Rotary tiller with automatic clutch device

An automatic clutch and rotary tiller technology, which is applied in the field of rotary tillers, can solve problems such as hidden dangers in operation safety, operation accidents, and operational errors, and achieve the effects of good automation, elimination of hidden safety hazards, and accurate and reliable control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Below, the specific implementation manners of the present invention will be further described in conjunction with the accompanying drawings.

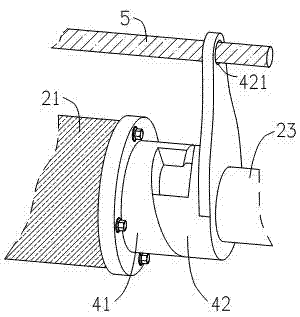

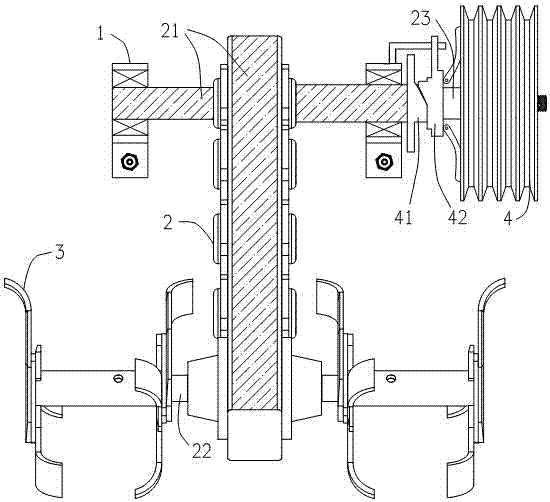

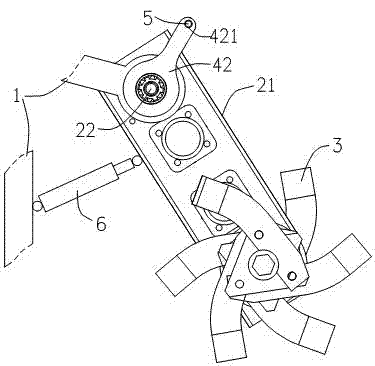

[0013] figure 1 It shows an embodiment of a rotary tiller with an automatic clutch device, including a liftable rotary tiller connected to the frame 1, and the rotary tiller includes a transmission box 2 and a rotary tiller installed on the output shaft 22 of the transmission box 2. Knife 3, transmission box 2 box body 21 is movable and hinged on the frame 1 with the transmission box 2 input shaft 23 as the axis, and the lifting mechanism is connected to the transmission box 2 box body 21, which can push the transmission box 2 box body 21 to rotate around the hinge axis With the working position of lifting rotary tiller 3; belt clutch wheel 4 is set on the transmission box 2 input shaft 23, and the separation seat 41 in the belt clutch wheel 4 is fixed on the transmission box 2 casing 21, and the separation claw in the belt clutc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com