Quantitative feeding device

A technology of feeding device and quantitative tray, which is applied in animal feeding device, poultry industry, animal husbandry and other directions, can solve the problems of poor quantitative accuracy, prone to failure, difficult operation, etc., and achieves low use cost and loss cost. Low, easy to clean and replace

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

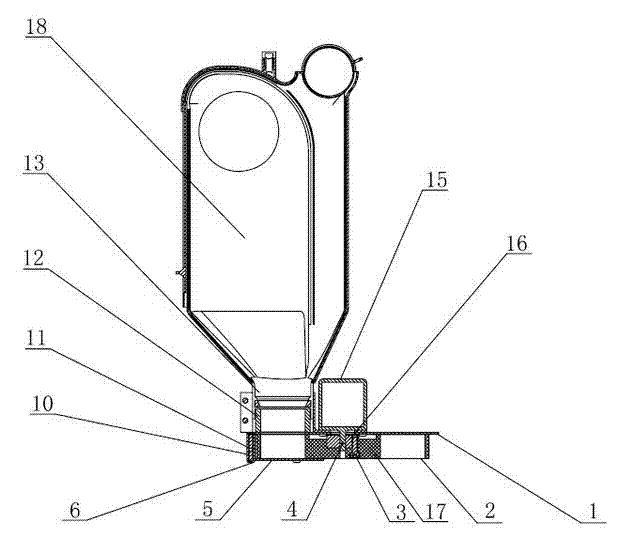

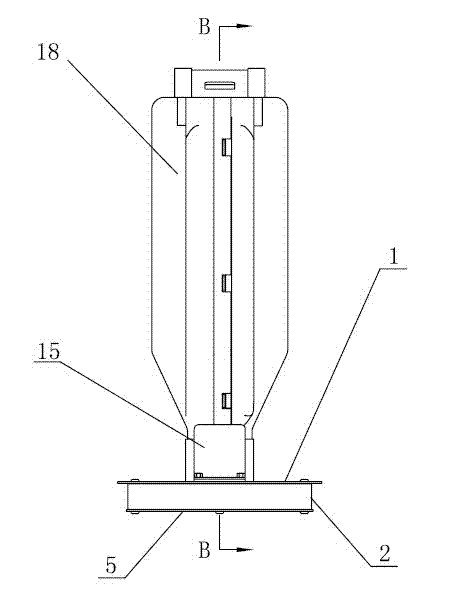

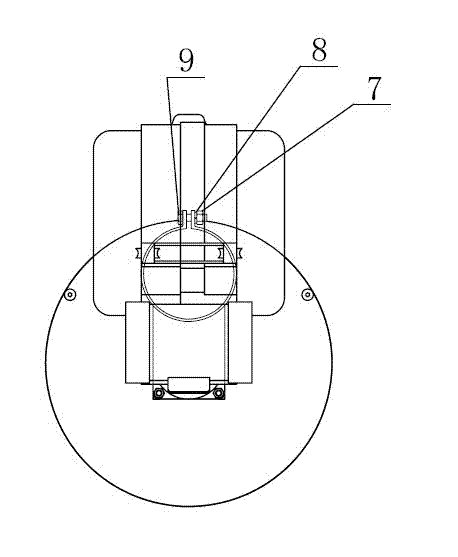

[0026] Such as Figure 1-3 As shown, a quantitative feeding device is arranged at the bottom of the feed cylinder 18, and the lower end of the discharge port at the bottom of the feed cylinder 18 is provided with a material guide cylinder 12 and a quantitative plate 2; the upper and lower ends of the quantitative plate 2 are open, and the upper end cover has a positioning Plate 1 is connected to the material guide cylinder 12 through the positioning plate 1; the lower end of the quantitative plate 2 is provided with a cover plate 5 corresponding to the position of the material guide cylinder 12, and the central axis of the quantitative plate 2 is provided with a central support block 17, and the quantitative plate 2 is connected to the cover. A material receiving space is formed between the material plate 5 and the central support block 17; the upper end of the central support block 17 has a driving device 15 for driving the quantitative disk 2 to rotate.

[0027] The fixed br...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com