Work fixture applied to large plate-shaped workpiece

A tooling fixture and disc-shaped technology, which is applied in the field of tooling fixtures for large disc-shaped workpieces, can solve problems such as difficult vertical clamping and positioning of large disc-shaped workpieces, and inability to vertically clamp and position large disc-shaped workpieces.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

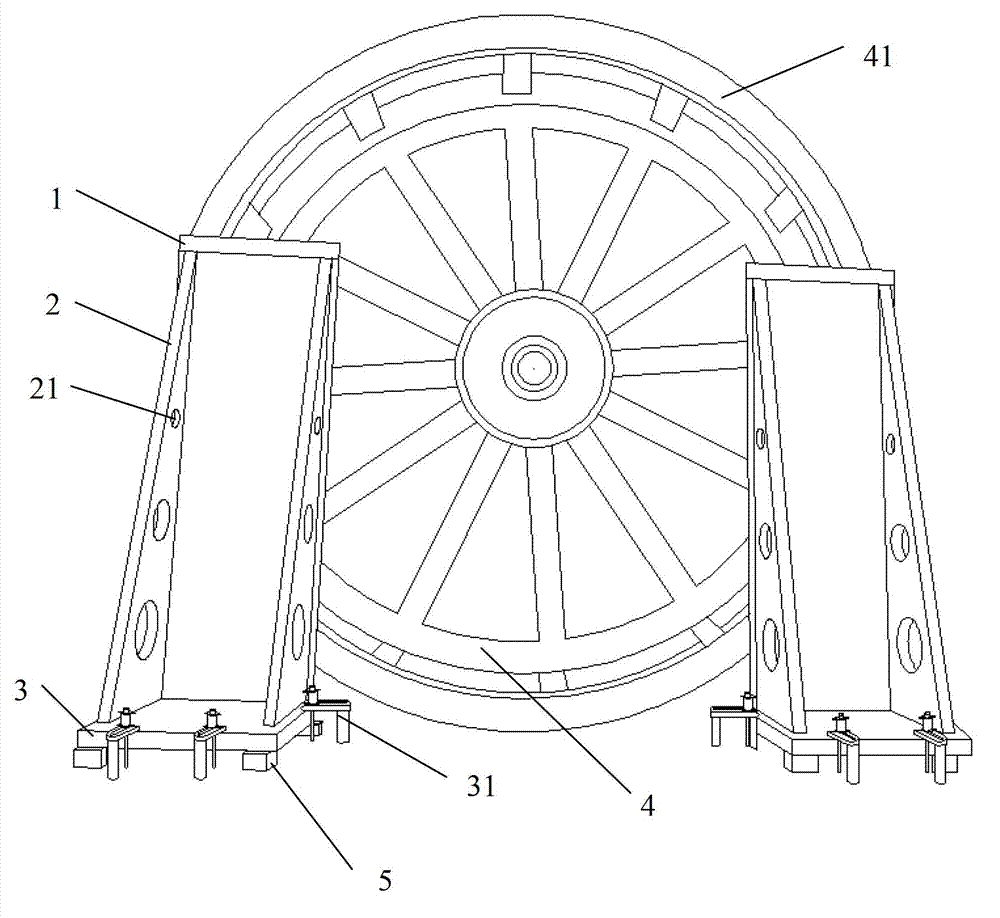

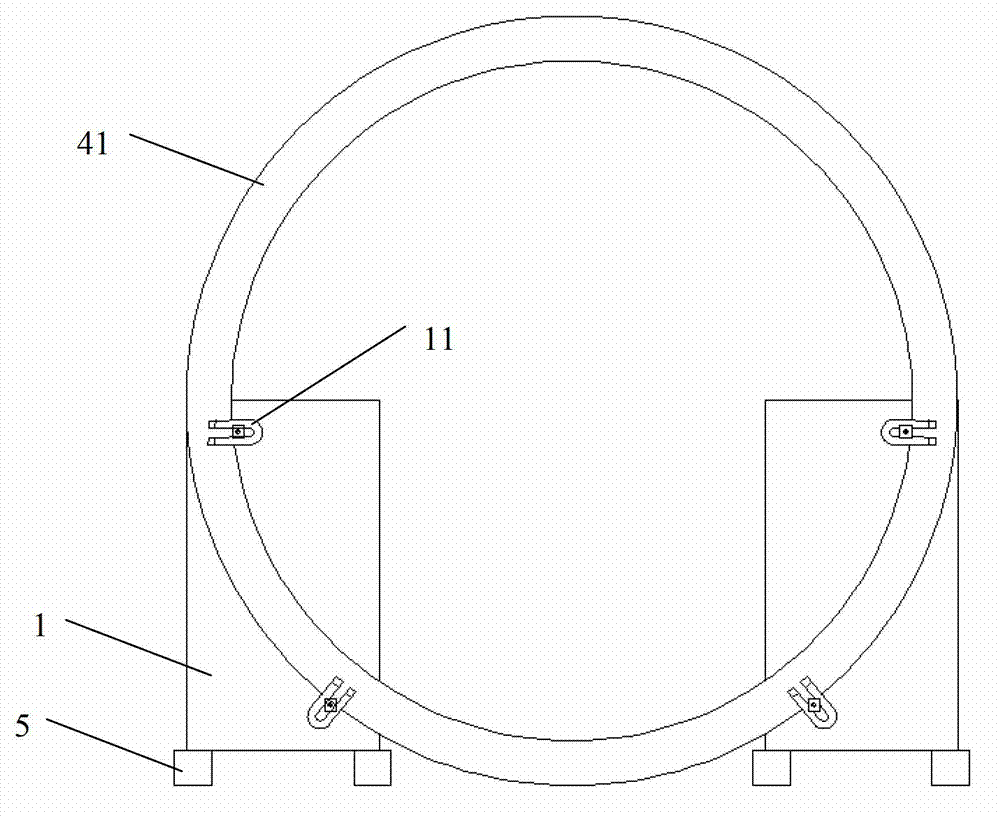

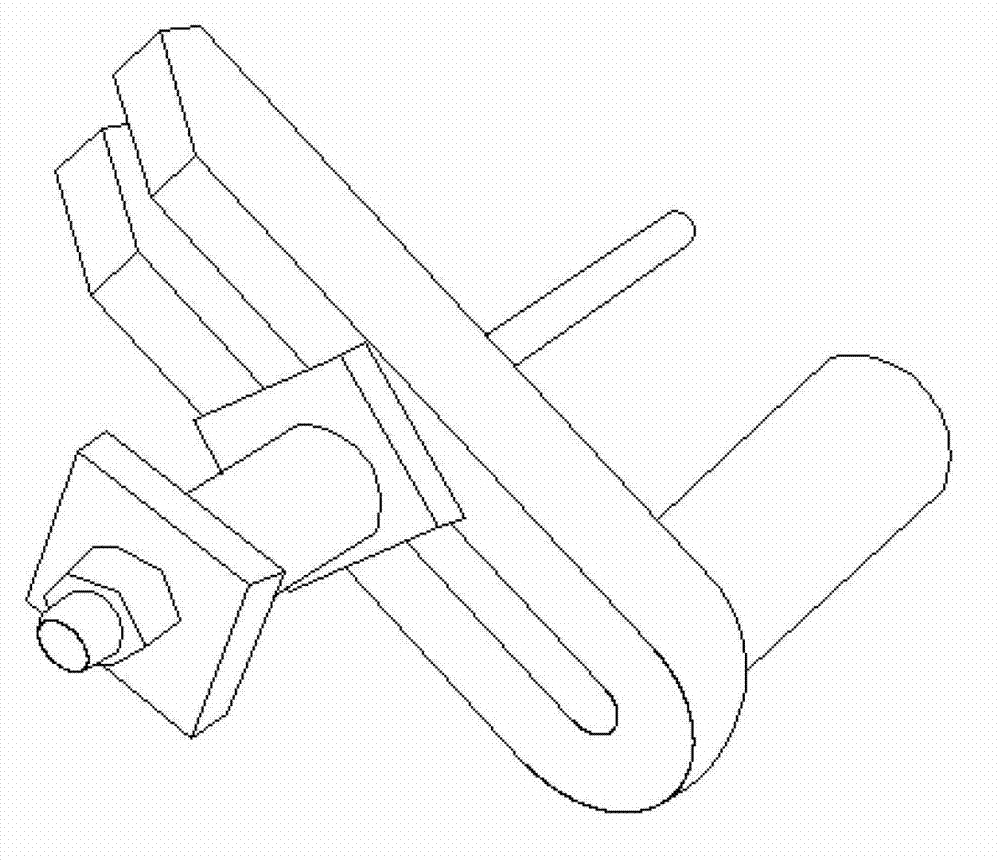

[0023] Such as figure 1 , 2 As shown, the present invention provides a kind of fixture for large disc-shaped workpiece, it is characterized in that: comprise bottom plate 3 and main board 1 perpendicular thereto, support plate 5 is connected between bottom board 3 and main board 1, the lower surface of bottom board 3 A number of support bases 5 are connected, a number of stabilizing frames 31 are arranged on the base plate 3 , and a number of buckles 11 are provided on the main board 1 .

[0024] The bottom plate 3, the main board 1 and the support plate 2 are integrally formed castings.

[0025] The bottom plate 3 is square.

[0026] The main board 1 is rectangular.

[0027] The number of said support plates 2 is 2, and its shape is a right triangle. The support plates are located at the edge of the base plate and the main board, and there are several hoisting holes 21 on the support plates.

[0028] The number of the hoisting holes 21 is three, and the radii of the hoist...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com