Running wheel of centrifugal machine

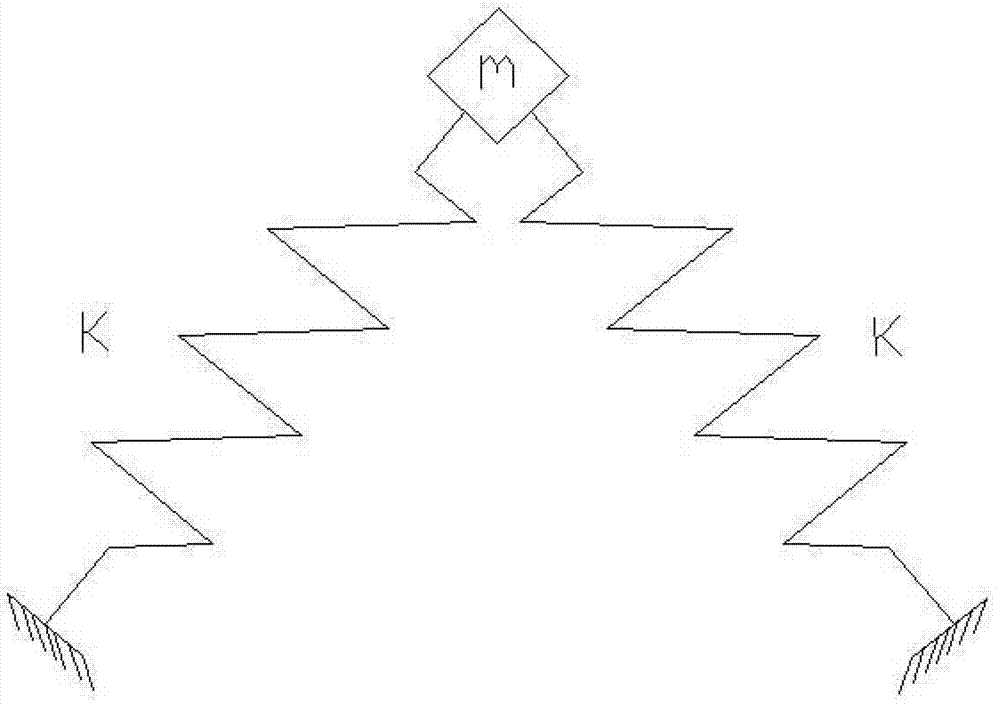

A centrifuge and running wheel technology, applied in the field of centrifuge accessories, can solve problems such as severe impact, and achieve the effect of eliminating high-frequency vibration and reducing radiation noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Method used

Image

Examples

Embodiment 1

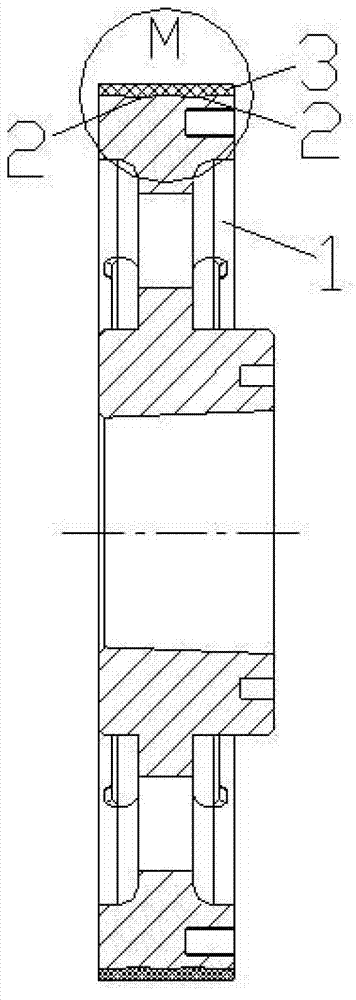

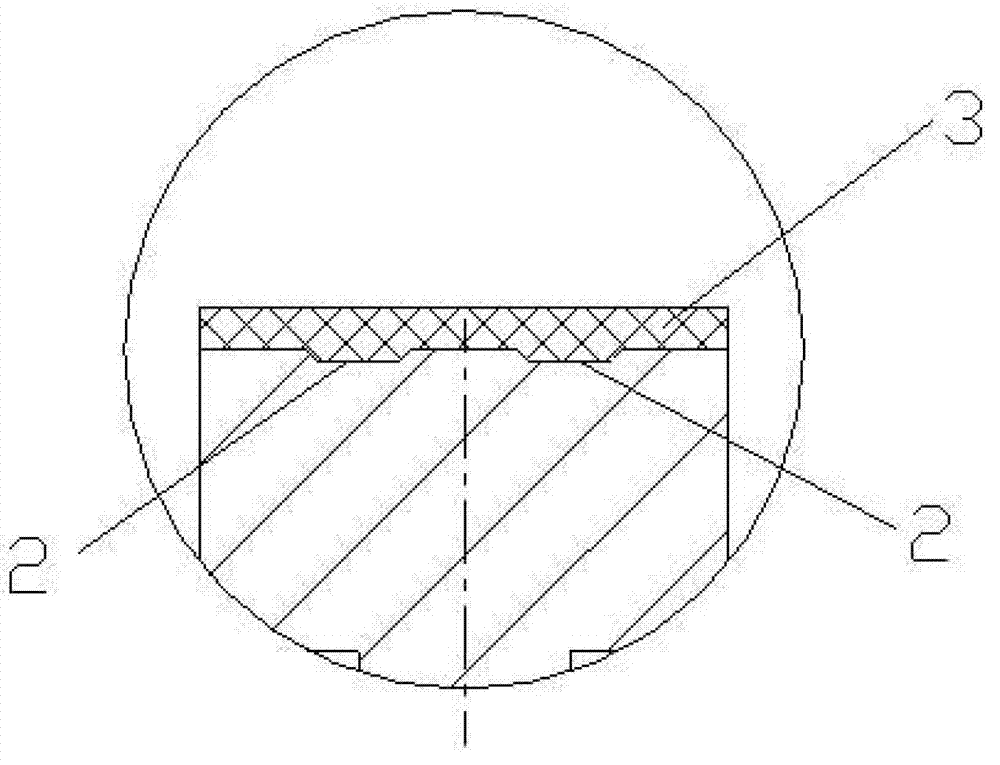

[0025] like figure 1 , figure 2 As shown, a centrifuge running wheel includes a wheel body 1, and more than one groove 2 is provided on the outer edge of the wheel body 1 and along the circumference of the outer edge, and the outer edge with the groove 2 is coated with wear-resistant elastic Layer 3, wherein the wear-resistant elastic layer 3 is made of polyurethane, so that the wear-resistant elastic layer 3 is arranged on the groove 2 and increases the holding force of the polyurethane, while minimizing the internal heat dissipation of the polyurethane material.

[0026] When there are more than two grooves 2 on the wheel body 1, the grooves 2 are symmetrically distributed on the wheel body 1.

[0027] The depth of each groove 2 is 1-5 mm, and the thickness of the wear-resistant elastic layer 3 is 6-12 mm, where the thickness of the wear-resistant elastic layer 3 does not count the groove depth. The shape of each groove 2 is an inverted isosceles trapezoid, and the acute ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com