Automatic detecting and packing equipment

A packaging equipment, automatic detection technology, applied in packaging, packaging protection, transportation and packaging, etc., can solve problems such as low work efficiency, hidden dangers, poor quality products, etc., to save labor costs, prevent man-made damage, and high work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

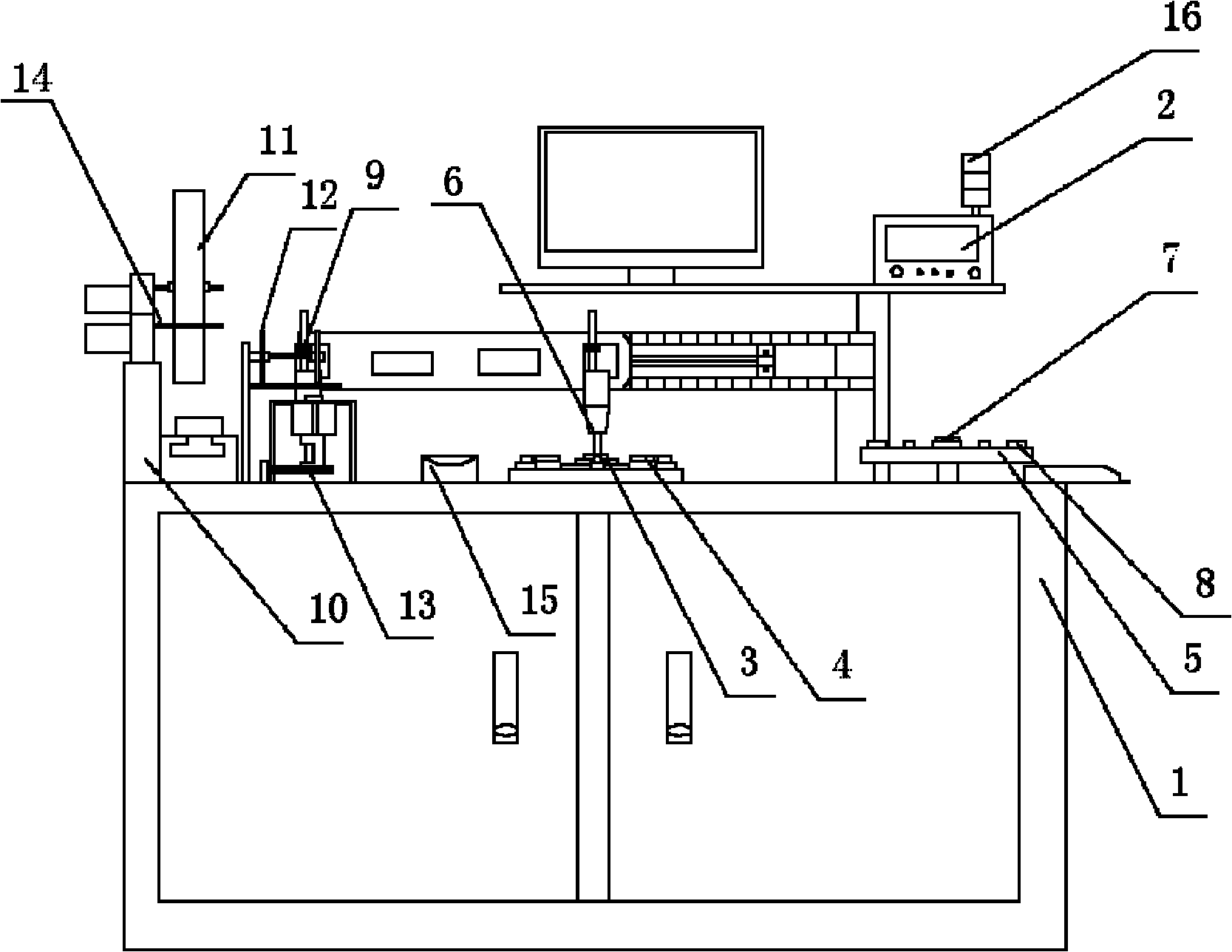

[0015] Embodiment: A kind of automatic detection packaging equipment, comprises frame 1, feeding device, detection device, controller 2, material receiving device and packaging device, take use direction as reference, feeding device, detection device, material receiving device and packaging device Fixedly arranged in sequence on the frame 1, the detection device is provided with a product positioning reference plane 3, and at least one camera 4 is also fixed on the detection device, and the camera 4 is fixedly positioned on the outer side of the product positioning reference plane 3 circumference, and the feeding device can Place the product on the product positioning reference surface 3 of the detection device, the camera 4 can sense the gap image between the product and the product positioning reference surface 3 and send a signal to the controller 2, and the controller 2 can compare the gap image with the standard value Comparing and making a judgment, the controller 2 can c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com