Clamping piece lifting mechanism

A lifting mechanism and clip technology, applied in the direction of lifting devices, etc., can solve the problems of low safety and reliability of actions, poor running stability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

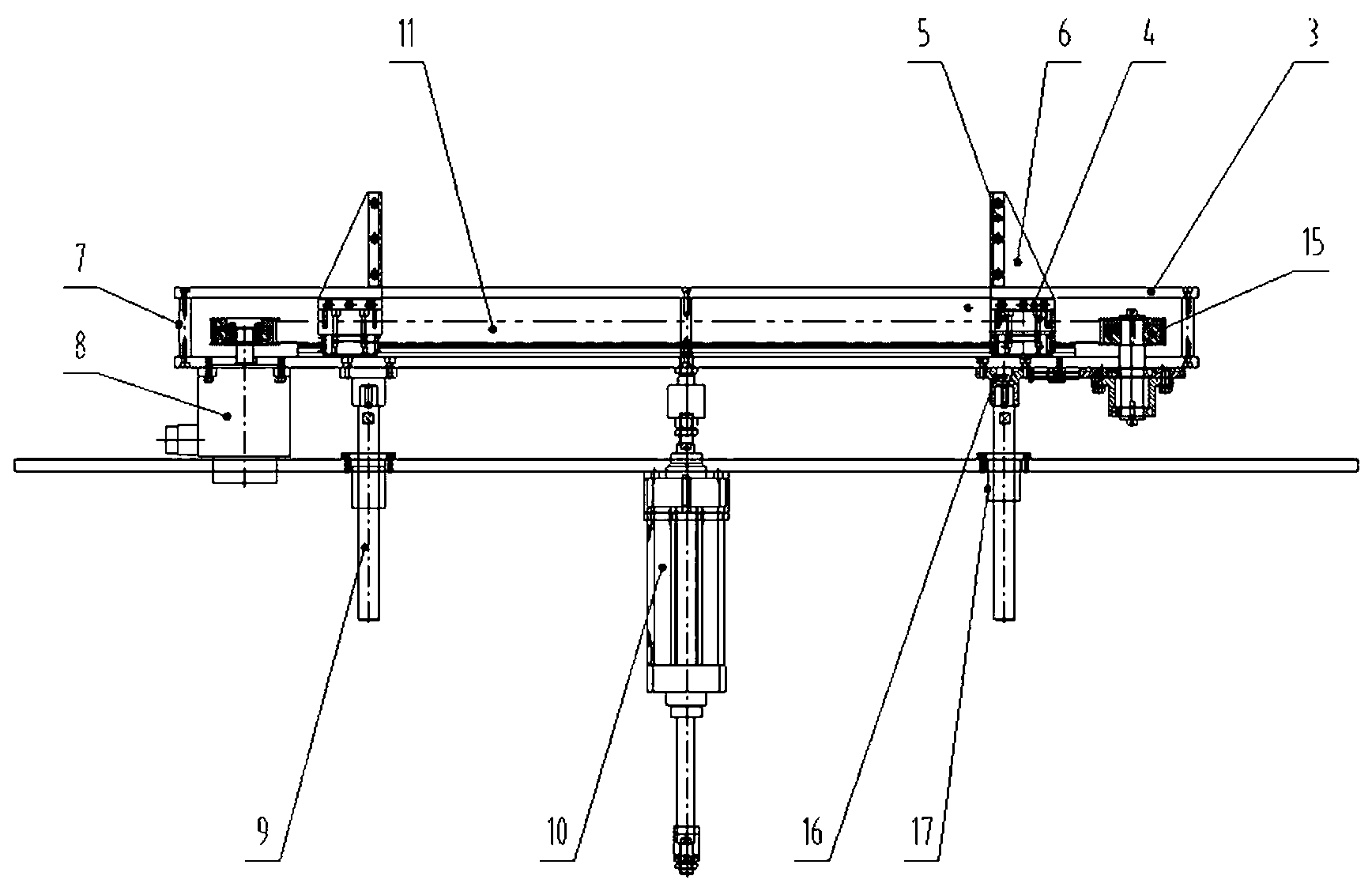

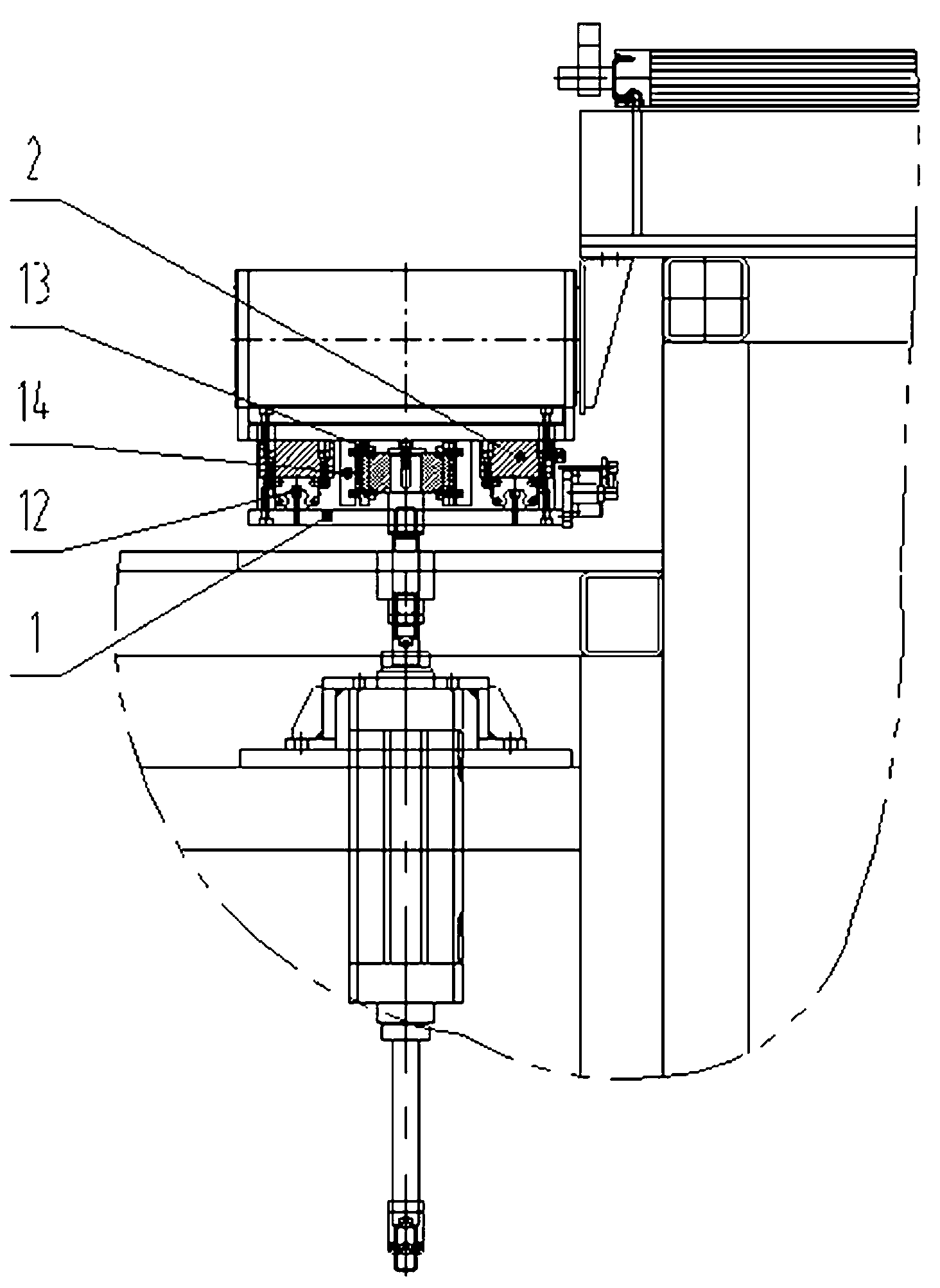

[0009] The present invention mainly comprises frame, and is located on the servomotor 8 on the frame, and its difference with the prior art is: the frame is provided with elevating device, and elevating device is set up with clip lifting platform. The clip lifting mechanism moves up and down relative to the frame under the influence of the cylinder, and the lifting guide rod guides the movement of the cylinder, which can enhance the smoothness and stability of this movement.

[0010] Lifting device is made of cylinder 10 and the elevating guide rod 9 that is located at both sides of cylinder respectively, and elevating guide rod is inserted in the linear bearing seat 17, and links to each other with clip lifting platform by guide rod seat 16. The clip lifting platform is composed of the rigid frame part of the clip lifting platform, the moving guide rai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com