Small hydraulic buffer impact test method and device

A hydraulic buffer and impact test technology, which is applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of not intuitively reflecting the buffer performance of the buffer, affecting the service life of the buffer, and high difficulty coefficient of the test, so as to achieve the test results Accurate and reliable, small workload and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The small hydraulic buffers in this embodiment refer to RB0604, RJ0805 and other series products.

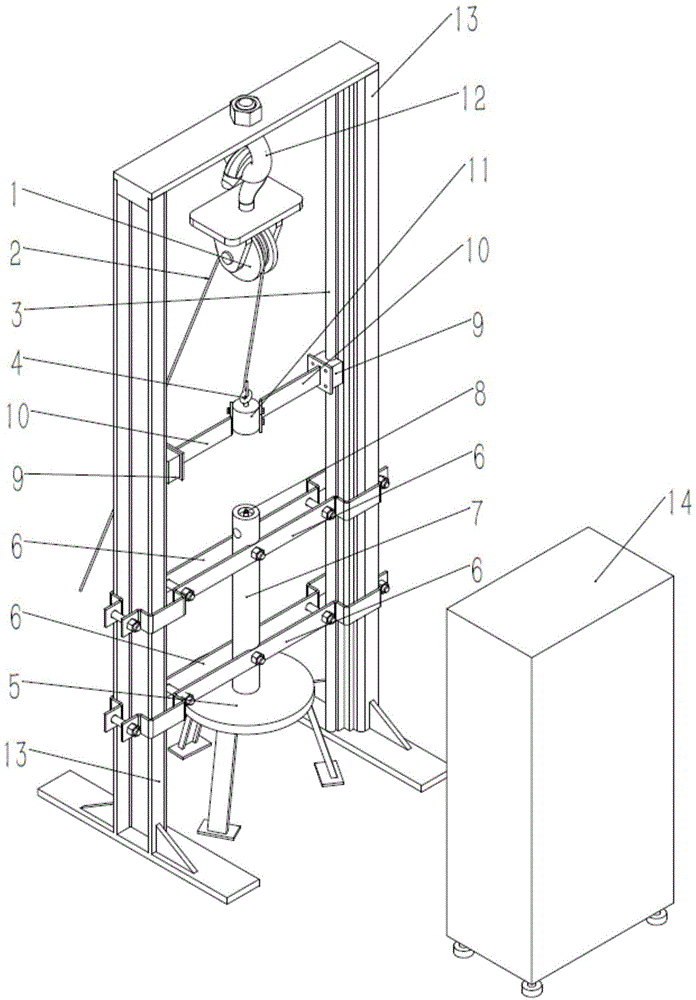

[0030] see figure 1 , Figure 2a and Figure 2b , the structural form of the small hydraulic buffer impact test device in the present embodiment is:

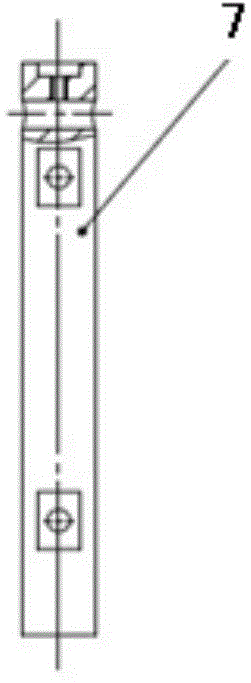

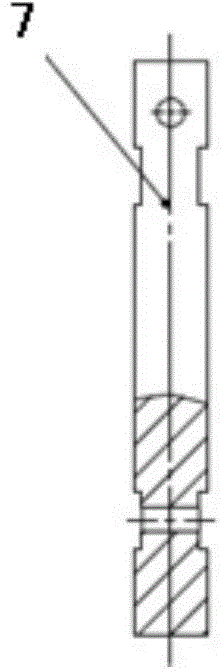

[0031] A door-shaped frame 13 composed of vertical rods 3 on both sides and cross beams connected to the tops of the vertical rods 3 on both sides is provided. In the frame 13, it is located at the lower part of the frame 13 and is fixed horizontally between the vertical rods on both sides. A splint 6 is provided, and the installation rod 7 standing upright on the support platform 5 is clamped in the splint 6. The splint 6 can be set as two upper and lower lines parallel to each other. To ensure that the hydraulic shock absorber is installed vertically and does not move axially or radially during the impact; a fixed pulley 1 is suspended on the beam by using the top ring 12, and one end of the wire rope 2 bypassing the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com