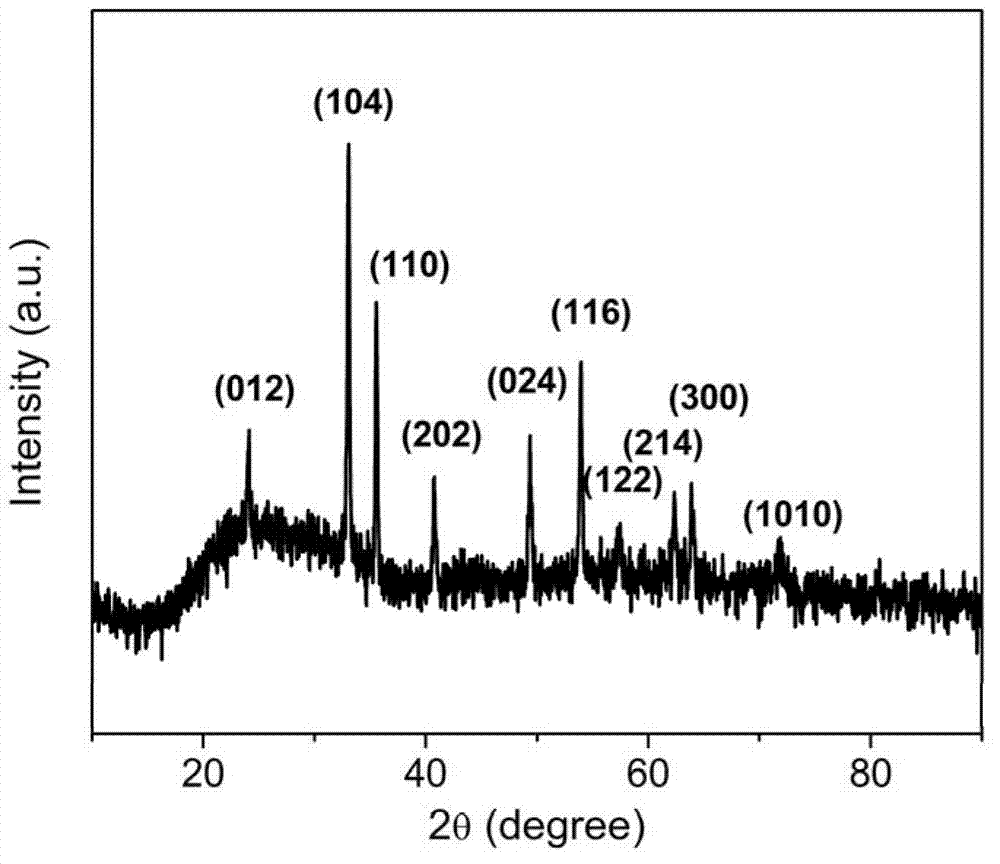

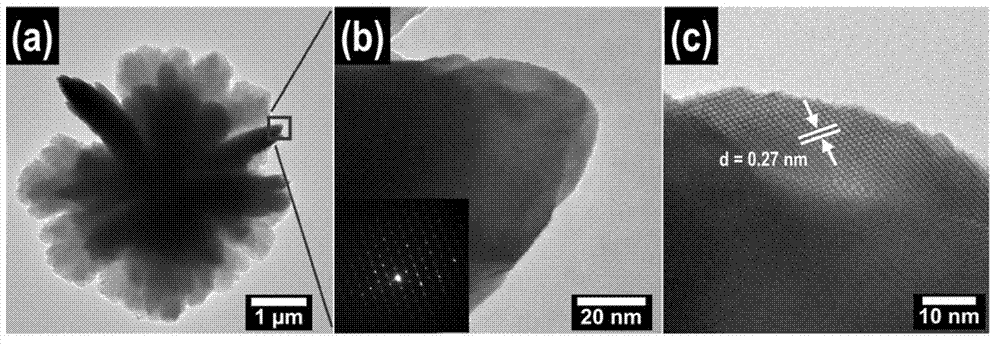

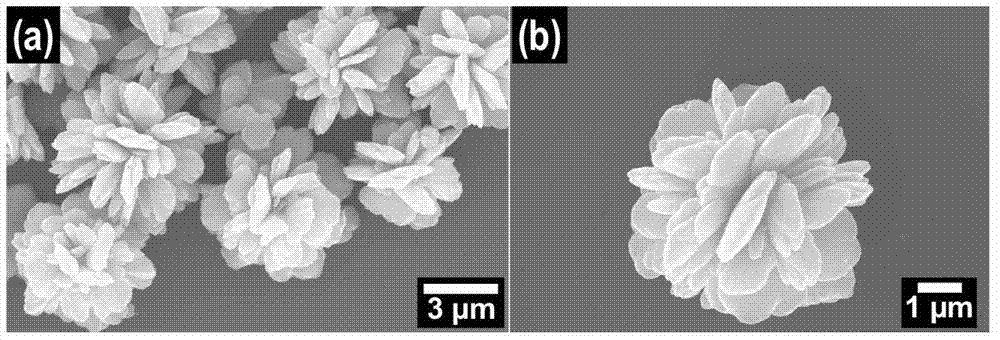

Preparation method of three-dimensional flower-shaped structure alpha-type ferric oxide

A ferric oxide, three-dimensional flower-like technology, used in iron oxide, iron oxide/hydroxide, nanotechnology for materials and surface science, etc., to achieve mild conditions, large output, and superior magnetic properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] (1) Weigh 0.33g (about 1mmol) of potassium ferricyanide, dissolve it in 10mL of deionized water, stir to dissolve it fully; prepare 10mL of 0.12g (3mmol) of sodium hydroxide solution, and mix it with Potassium ferricyanide solution mixed. The concentration of potassium ferricyanide in the mixed solution is 0.05M, and the concentration of sodium hydroxide is 0.15M.

[0022] (2) Add 0.384g (about 6.4mmol) of urea to the mixture, stir to dissolve it fully, and obtain a light yellow clear solution. The concentration of urea in the mixed solution is 0.32M.

[0023] (3) Transfer the above-mentioned yellow clear solution to a 50mL polytetrafluoroethylene-lined stainless steel reaction kettle, seal it and raise the temperature to 180°C for 12h.

[0024] (4) Cool down to room temperature naturally after the reaction is complete, centrifuge the sediment at the bottom of the kettle, wash with absolute ethanol and deionized water for 2 to 3 times, and dry the obtained product at ...

Embodiment 2

[0031] (1) Weigh 0.33g (about 1mmol) of potassium ferricyanide, dissolve it in 10mL of deionized water, stir to dissolve it fully; prepare 10mL of 0.08g (2mmol) of sodium hydroxide solution, and mix it with Potassium ferricyanide solution mixed. The concentration of potassium ferricyanide in the mixed solution is 0.05M, and the concentration of sodium hydroxide is 0.10M.

[0032] (2) Same as embodiment 1.

[0033] (3) The above-mentioned yellow clear solution was transferred to a polytetrafluoroethylene-lined stainless steel reaction kettle with a capacity of 50mL, sealed and heated to 180°C for 16h.

[0034] (4) Same as embodiment 1.

Embodiment 3

[0036] (1) Same as embodiment 1.

[0037] (2) Add 0.192g (about 3.2mmol) of urea to the mixture, stir to dissolve it fully, and obtain a light yellow clear solution. The concentration of urea in the mixed solution is 0.16M.

[0038] (3) Transfer the above-mentioned yellow clear solution to a stainless steel reaction kettle lined with polytetrafluoroethylene with a capacity of 50mL, seal it and raise the temperature to 180°C for 16h.

[0039] (4) Same as embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap