High-strength steel sheet excellent in workability and cold brittleness resistance, and manufacturing method thereof

A manufacturing method and steel plate technology, applied in the direction of manufacturing tools, furnace types, furnaces, etc., can solve the problems of insufficient assurance of low-temperature brittleness and deterioration of low-temperature brittleness, and achieve the effect of excellent strength and ductility and excellent balance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

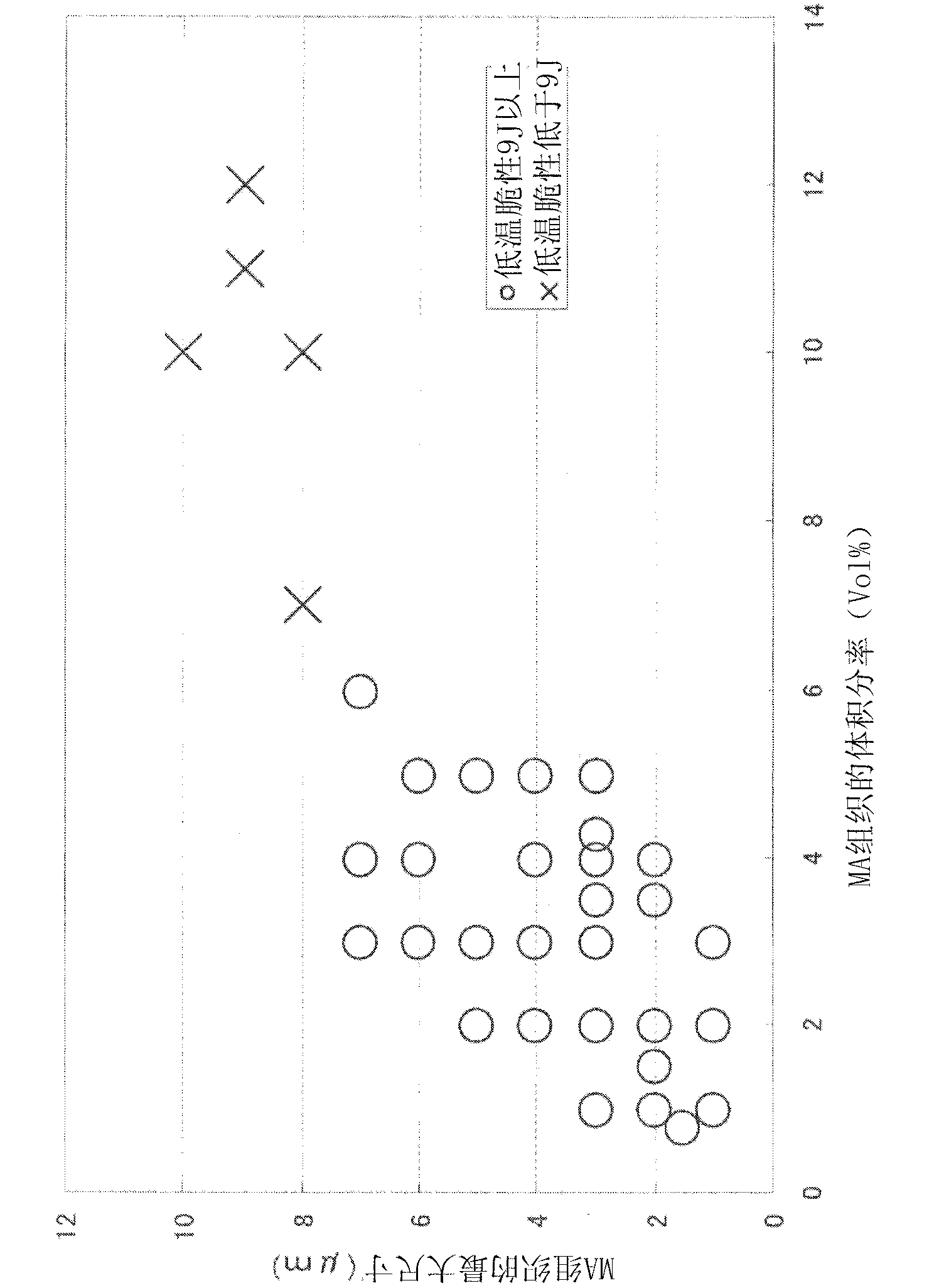

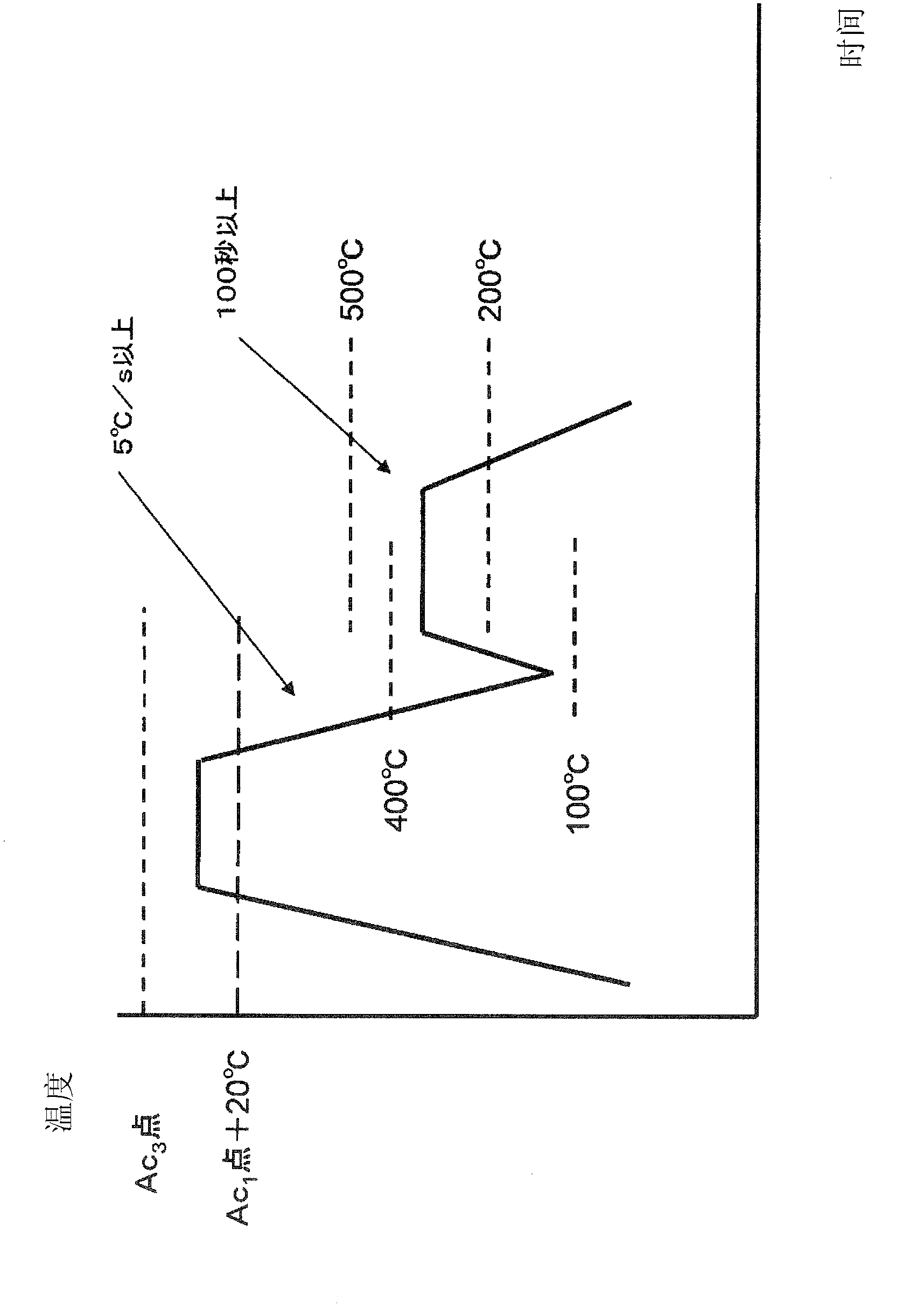

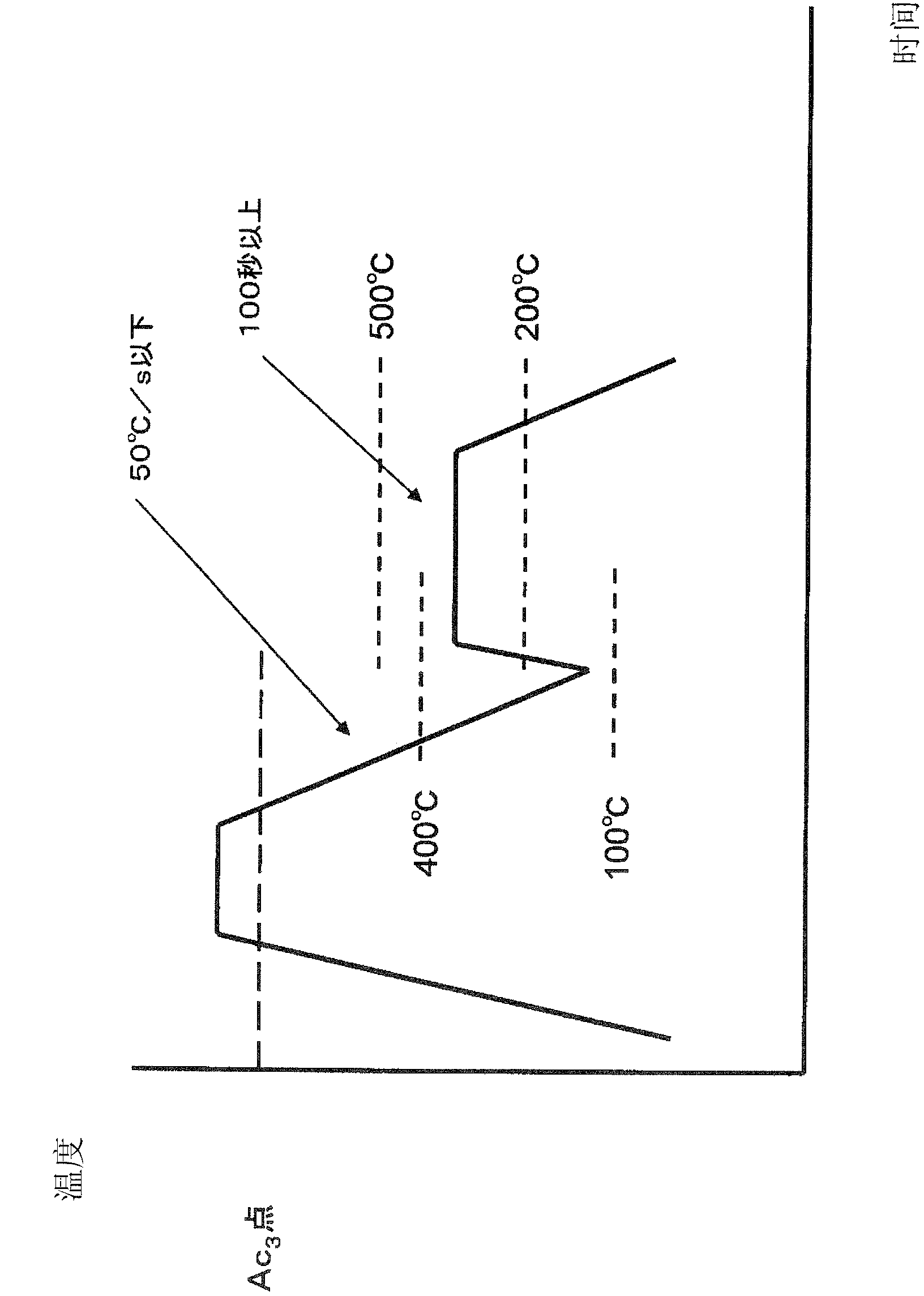

[0022] The inventors of the present invention have made intensive studies in order to improve the workability and low-temperature brittleness of high-strength steel sheets having a tensile strength of 1180 MPa or more. As a result, it was found that in order to obtain a high-strength steel sheet that not only maintains a high strength of 1180 MPa or more, but also has excellent workability and low-temperature brittleness, if the composition is properly controlled, the metal structure of the steel sheet can be changed to ferrite in a specific ratio. body, retained austenite (hereinafter referred to as "retained γ"), MA structure, bainitic ferrite and / or tempered martensite, if the metal structure is properly controlled, both strength and workability can be ensured , and can improve the low-temperature brittleness, thereby completing the present invention. In particular, the present invention is characterized in that it is found that a mixed structure (MA structure: Martensite-A...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com