Method for deacidifying through utilizing soluble tetraborate in supercritical CO2 state

A tetraborate, soluble technology, applied in the direction of waste paper post-processing, etc., to achieve the effect of low viscosity, good heat and mass transfer effect, and improved tear and folding resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

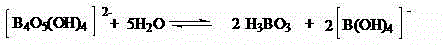

Method used

Image

Examples

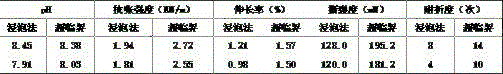

Embodiment 1

[0038] Take about 126g of New York Times newspaper in 1989 and put it into 2L supercritical CO 2 In the treatment kettle, under the conditions of 25MPa and 36°C, inject 700ml of the deacidification agent potassium tetraborate saturated aqueous solution-ethanol mixed solution (volume ratio 60:40) from the auxiliary pump, and treat for 1.8h, CO 2 The flow rate of the fluid is 0.002t / h. Take the deacidification agent with the same proportion and volume, and use the soaking method to treat the paper of the same quality as a reference. Supercritical CO 2 After treatment, the pH value of the paper is 8.38 (8.45 by soaking method), and the pH is well preserved after aging; the tensile strength of the paper is 2.72 (1.94 by soaking method), which is 58.2% higher than that before deacidification; the elongation is 1.57 (1.94 by soaking method 1.21), 80.4% higher than before deacidification, tearing degree 195.2 (128.0 by immersion method), 60% higher than before deacidification; fold...

Embodiment 2

[0042] Take about 106g of New York Times newspaper in 1989 and put it into 2L supercritical CO 2 In the treatment kettle, under the conditions of 24MPa and 36°C, inject the deacidification agent tetraborate (sodium tetraborate, potassium tetraborate, calcium tetraborate, etc.) saturated aqueous solution-ethanol mixed solution (volume ratio of 50:50) 800ml, treatment 2h, CO 2 The flow rate of the fluid is 0.002t / h. Take the saturated aqueous solution of the deacidification agent listed in the table below, mix it with ethanol according to the same solvent volume ratio, and use the same supercritical condition to treat the paper as a reference. From the comparison of deacidification results, it can be seen that the deacidification effect using borate is significantly better than that obtained in patent 200910039000.1. After aging at 105℃ for 72 small tests, the strength remains good.

[0043] The pH comparison after deacidification is shown in the table below:

[0044] ...

Embodiment 3

[0046] Take about 308g of New York Times newspaper in 1989 and put it into 2L supercritical CO 2 In the treatment kettle, under the conditions of 24MPa and 36°C, inject the deacidification agent from the auxiliary pump, each saturated aqueous solution of sodium tetraborate-ethanol mixed solution (50:50 by volume) 2000ml, treat for 4h, CO 2 The flow rate of the fluid is 0.002t / h. Take the deacidification agent with the same proportion and volume, and use the soaking method to treat the paper of the same quality as a reference. After supercritical treatment, the pH value of the paper is 8.33 (8.21 by soaking method), and the pH is well preserved after aging; the tensile strength of the paper is 2.70 (2.34 by soaking method), which is 56.9% higher than that before deacidification; the elongation is 1.54 (soaked method 1.21), which is 77.0% higher than before deacidification; tearing degree is 194.0 (soaking method 171.2), which is 59.0% higher than before deacidification; foldin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com