Automatic deviation adjusting wellhead sealing device

A wellhead sealer, automatic technology, applied in the direction of sealing/packing, wellbore/well parts, earthwork drilling and production, etc., can solve the problems of frequent packing replacement, lower production efficiency, shortened service life of sealing devices, etc., to avoid Effects of crude oil loss, improvement of production efficiency, and extension of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

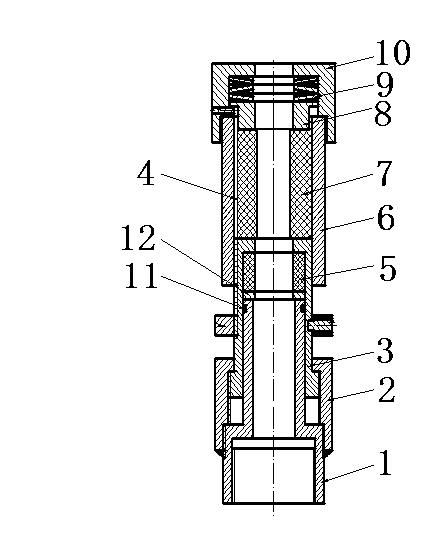

[0011] combined with figure 1 , to further describe the present invention:

[0012] The present invention is mainly composed of a connector 1, a fixed cap 2, a lower pressure cap 3, a lower packing 5, an upper stuffing box 6, an upper packing 7, a gland 8, and a pressure cap 10. The lower part of 2 is connected by thread, the upper part of connector 1 is provided with lower packing 5, the upper part of fixed cap 2 and the lower end of lower pressure cap 3 are connected by thread, and the upper part of lower pressure cap 3 is fixed with upper stuffing box 6, upper plate The root 7 is fixed in the upper stuffing box 6, the top of the upper packing 7 is fixed with the gland 8, the gland 10 and the upper stuffing box 6 are threaded, and the contact between the inner wall of the upper stuffing box 6 and the upper packing 7 A plurality of grooves 4 are provided on the surface, disc springs 9 are arranged in the pressure cap 10 and the gland 8 , and a gasket 12 and a sealing ri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com