Suction opening structure of compressor

A suction port and compressor technology, which is applied in the field of compressors, can solve the problems of ceramic tube length not being too long, high installation precision of liquid storage tank, and reduced heat insulation effect, so as to reduce adverse effects, easy to ensure assembly tolerance, The effect of increasing the insulating area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

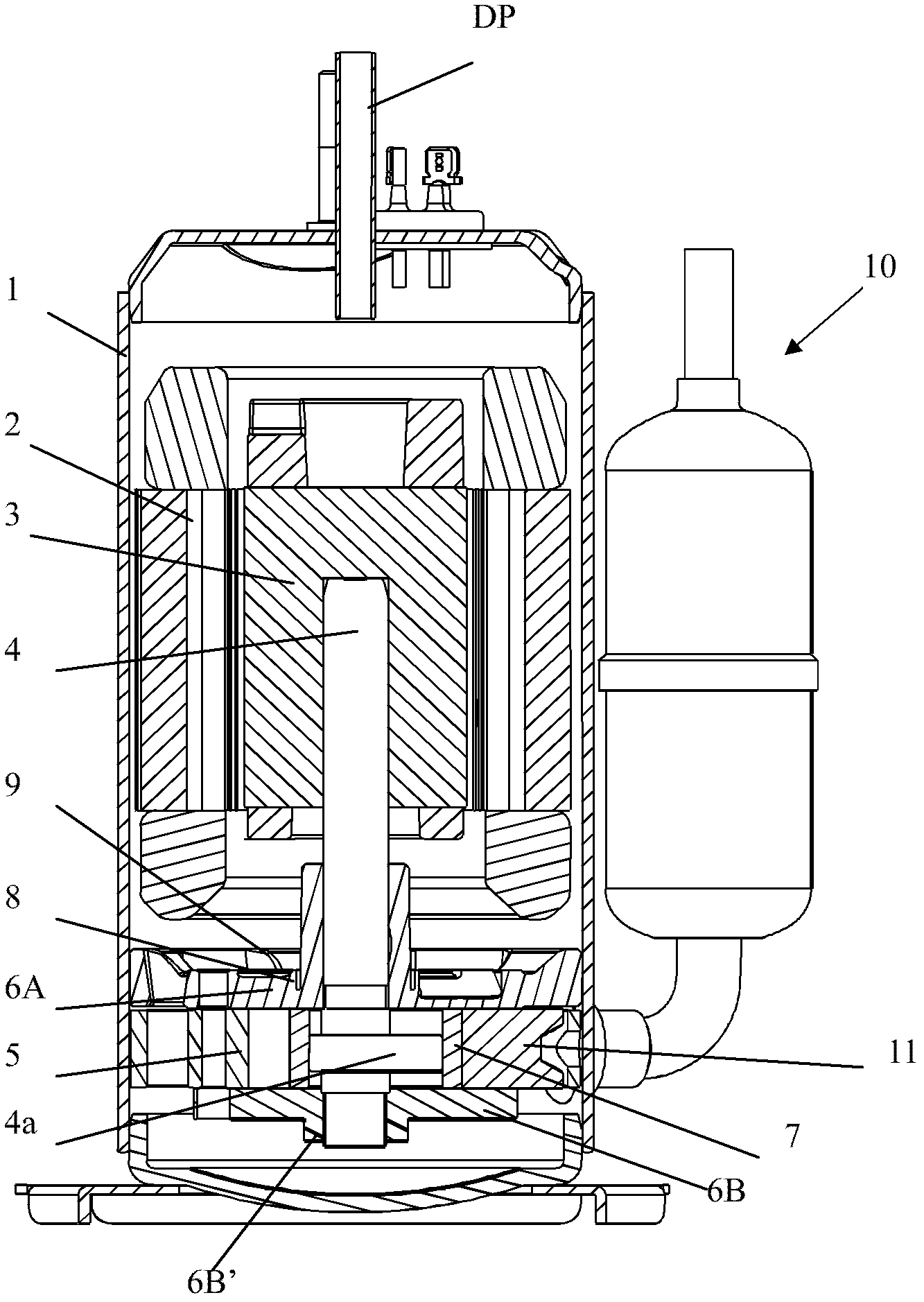

[0020] The structure of the rotary compressor of the present invention will be described in detail below with reference to the accompanying drawings.

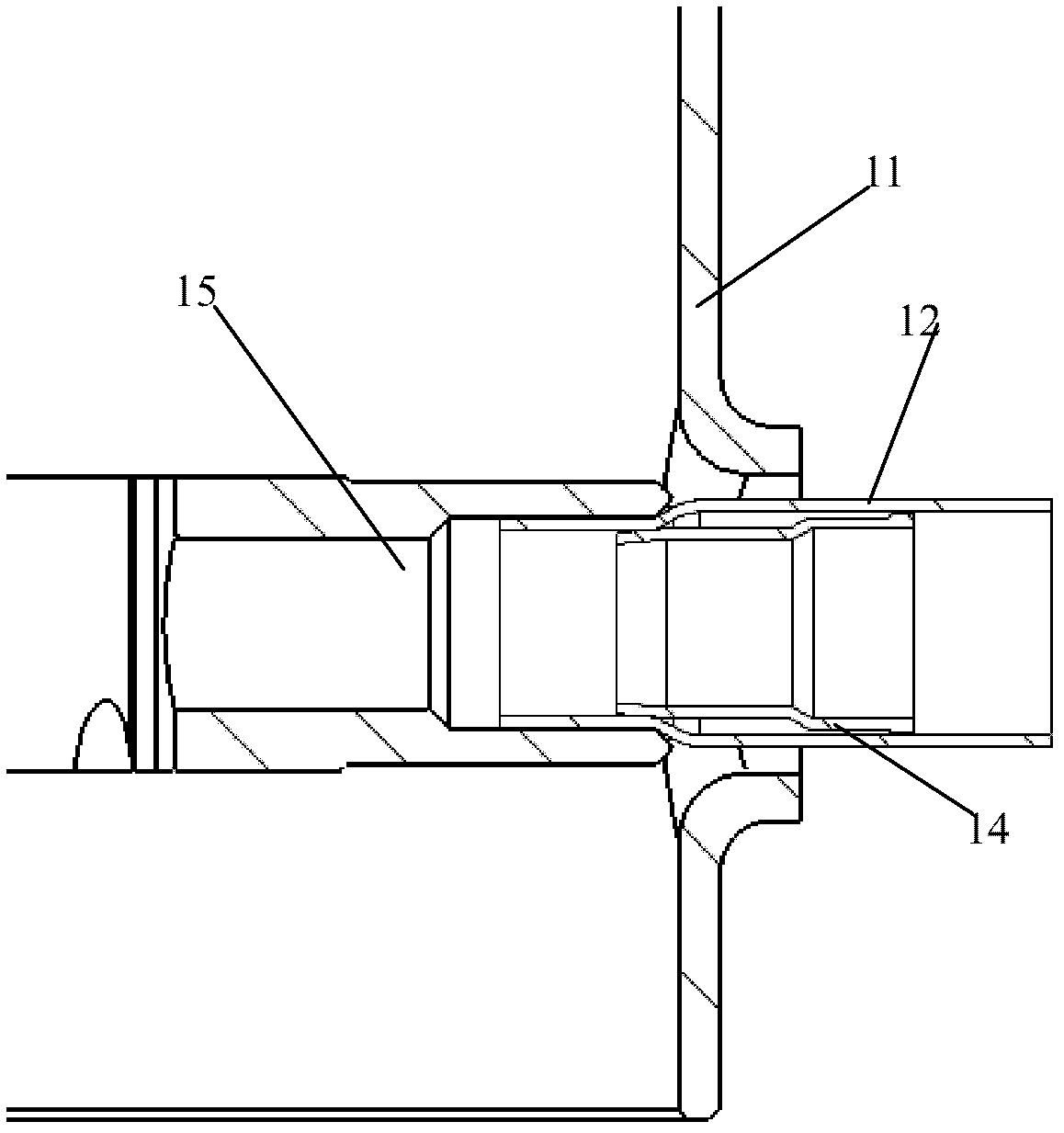

[0021] The structure of the compressor of the present invention is basically the same as that of the prior art, and its electric structural part includes: a stator, a rotor and a crankshaft. The stator and the rotor are arranged inside the casing, the center of the rotor is press-fitted and installed on the crankshaft, and the lower part of the crankshaft is provided with a compression structure for sucking and compressing the refrigerant gas. The compression structure part includes: a circular cylinder fixedly arranged on the inner peripheral surface of the casing; an upper bearing and a lower bearing which are closely fixed on the upper and lower sides of the cylinder while the crankshaft passes through and is supported; On the eccentric part, the roller ring rotates eccentrically in the cylinder under the action of the crank...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com