Fastening connecting component of vehicle plastic part

A technology for fastening connections and plastic parts, applied in the direction of connecting components, pins, mechanical equipment, etc., can solve the problems of fatigue fracture of plastic parts, increase the difficulty of molds for plastic parts, and unguaranteed reliability, so as to reduce manufacturing costs and molds Simple, easy assembly and disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

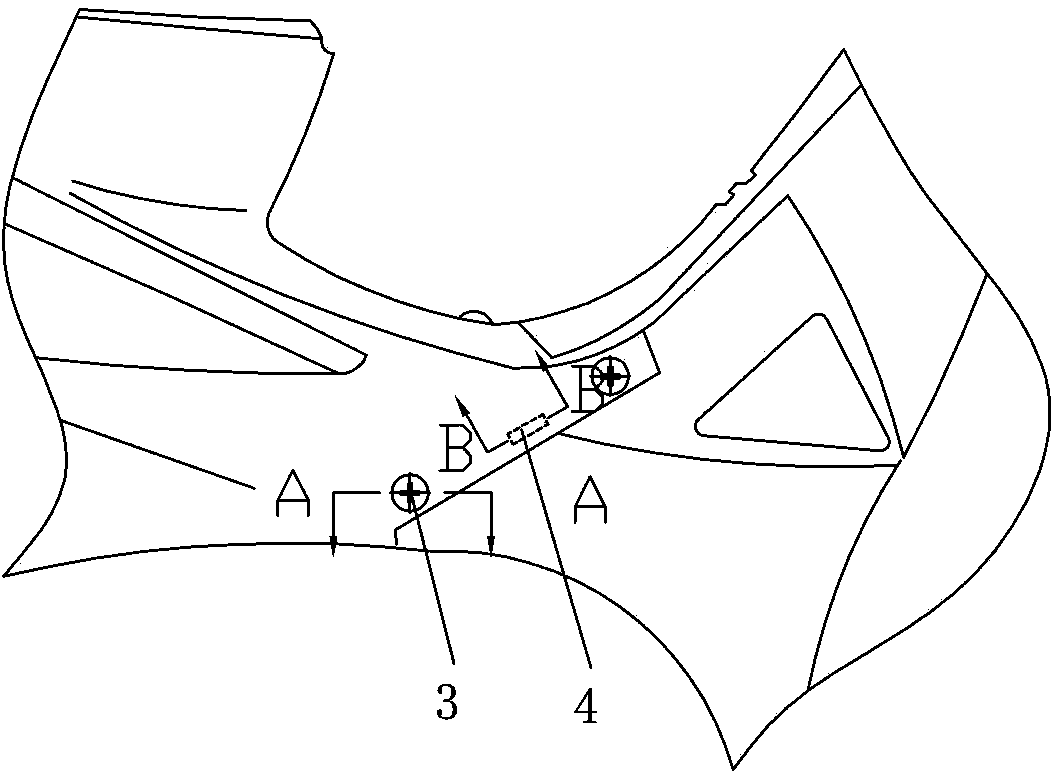

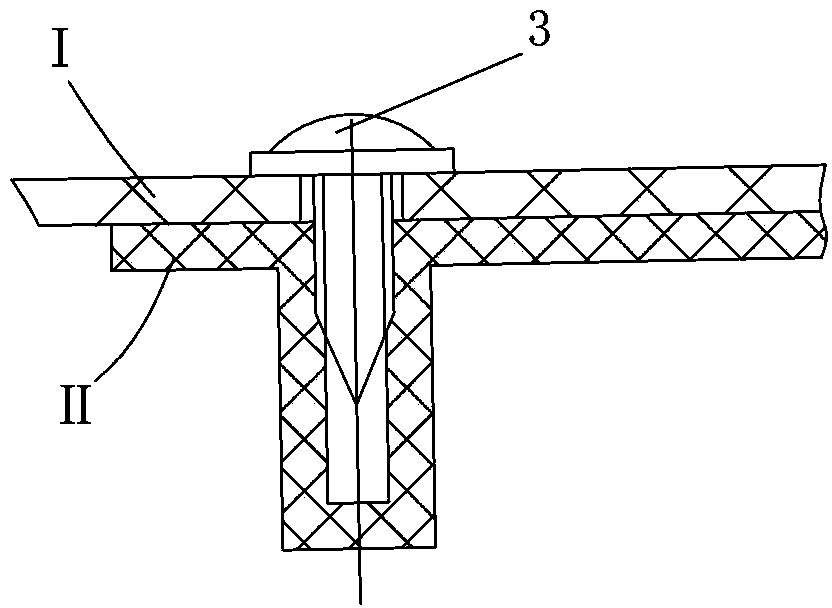

[0027] Such as Figure 4 The shown fastening and connecting assembly of plastic parts for vehicles is composed of quick-inserting nails 1 and quick-inserting sleeves 2, both of which are plastic parts. to combine Figure 5 It can be seen that the quick insertion screw 1 is composed of a first inverted cone 11 and a second inverted cone 12 arranged coaxially, the first inverted cone 11 is located above the second inverted cone 12, and the first inverted cone 11 and the second inverted cone 12 are connected. into one. A first annular boss 13 and a second annular boss 14 are arranged on the second inverted cone 12 , and the first annular boss 13 and the second annular boss 14 are spaced up and down and parallel to each other. to combine Figure 6 As shown, the upper end of the quick insertion sleeve 2 has an end 21 , the lower part of the quick insertion sleeve 2 is divided into petals, and the lower end of each petal is bent toward the axis of the quick insertion sleeve 2 to ...

Embodiment 2

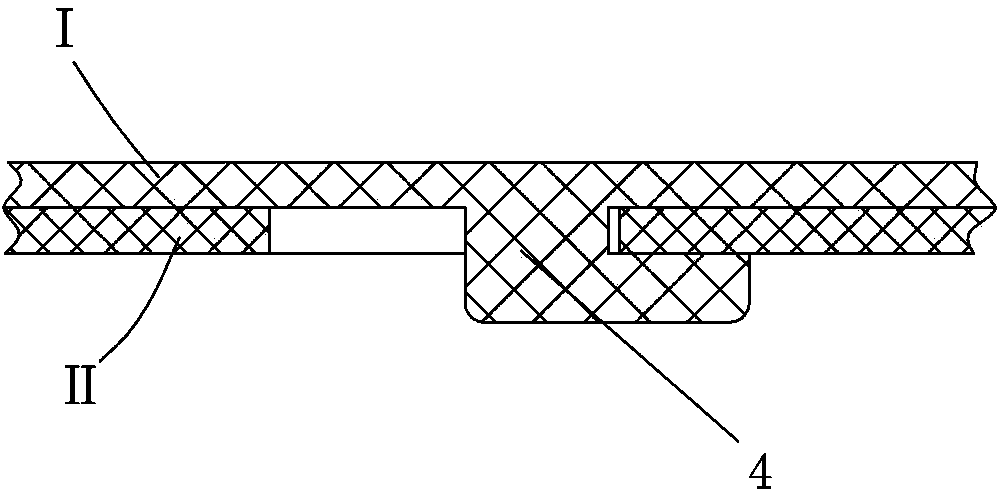

[0034] Such as Figure 8 , Figure 9 The shown fastening and connecting assembly of plastic parts for vehicles is composed of quick-inserting nails 1 and quick-inserting sleeves 2, both of which are plastic parts. The structure of the quick-insert sleeve 2 is the same as that of the quick-insert sleeve 2 in Embodiment 1, and will not be repeated here. The quick insertion screw 1 is composed of a first inverted cone 11, a second inverted cone 12 and a third inverted cone 15 arranged coaxially. The second inverted cone 12 is connected below the first inverted cone 11, and the third inverted cone 15 is connected to the Below the second inverted cone 12 , and the third inverted cone 15 is integrated with the first and second inverted cones 11 and 12 . The diameter of the upper end of the second inverted cone 12, the upper end diameter of the third inverted cone 15, the diameter of the first annular boss 13 and the diameter of the second annular boss 14 are all smaller than the dia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com