Bolt locking and looseness-preventing device

A bolt and anti-loosening technology, which is applied in the direction of bolts, threaded fasteners, locking fasteners, etc., can solve the problems of easy loosening of assembly parts, difficulty in controlling the assembly gap, and unqualified assembly, so as to eliminate the assembly gap Difficult to control, precise locking positioning, strong applicability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

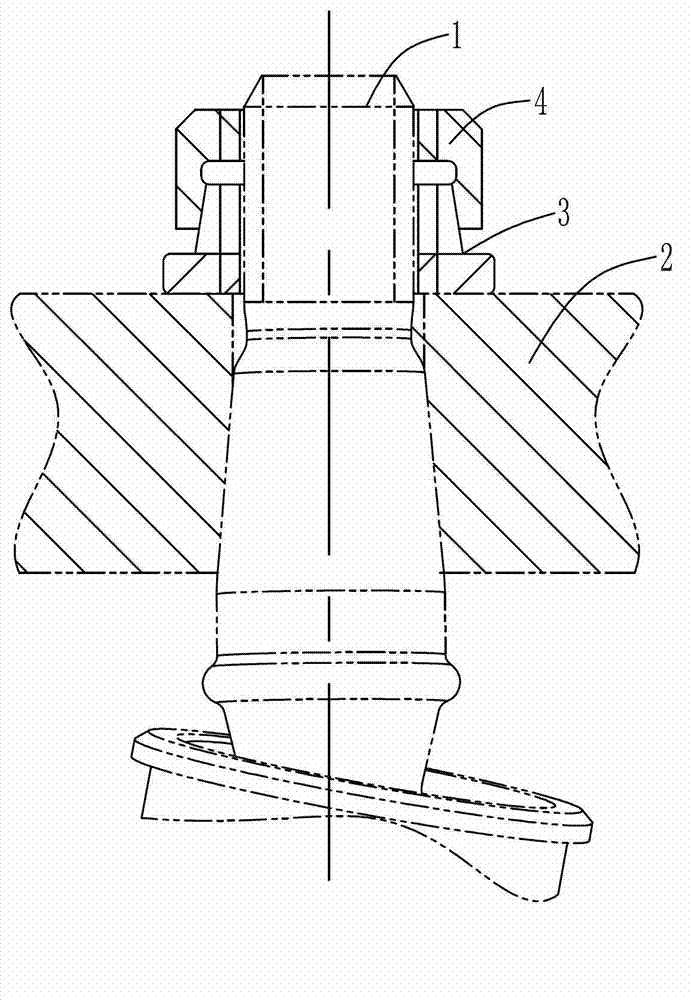

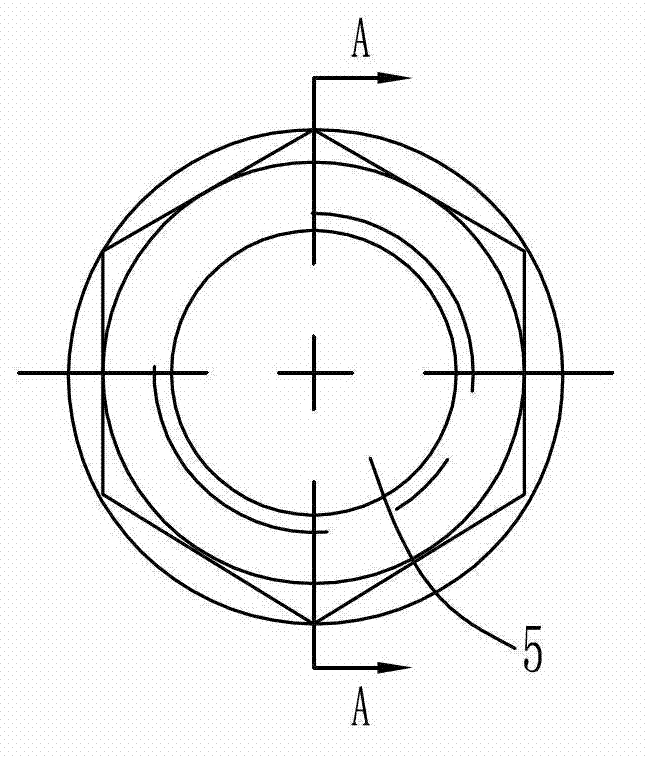

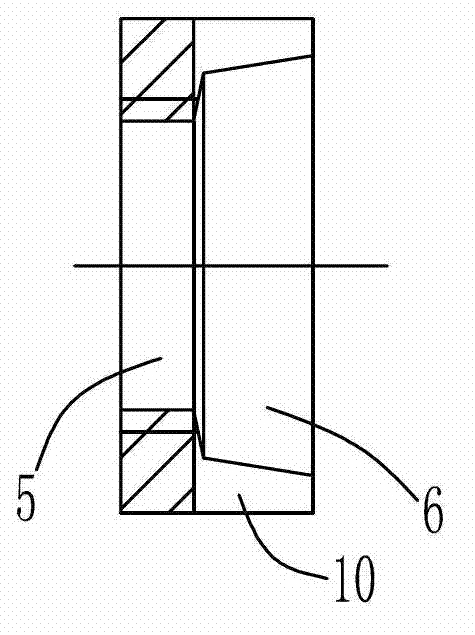

[0025] Such as figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 As shown, the present invention is made of bolt 1, lock nut 4, lock seat 3 and fitting 2 etc., the end of bolt 1 passes through fitting 2, and the end of bolt 1 is sleeved with lock nut 4. One end of the inner hole of the locking nut 4 is a screw hole section 5 , and the other end is a tapered hole section 6 . The lock nut 4 is threadedly matched with the bolt 1 through the screw hole section 5, and the outer contour of the screw hole section 5 is a regular hexagon, so as to be operated by a wrench. The tapered hole section 6 of the lock nut 4 is close to the fitting 2, and the inner wall of the tapered hole section 6 is a tapered surface with a small inside and a big outside, and the taper is 15°-20°. A plurality of openings are formed in the axial direction on the inner wall of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com