Small volume electrical connector assembly and its plug and socket

An electrical connector, small-volume technology, applied in the parts, connections, electrical components and other directions of the connecting device, can solve the problem that it is difficult to meet the requirements of miniaturization and portability, the electrical connector components are difficult to meet the requirements of vibration, impact, electrical components, etc. Problems such as bloated connector components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

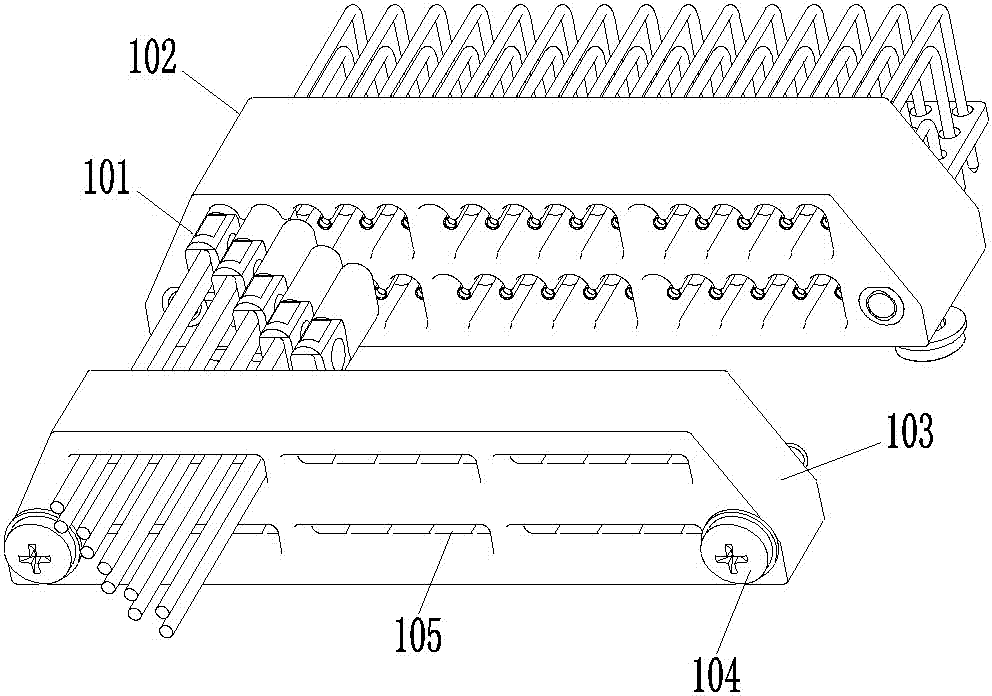

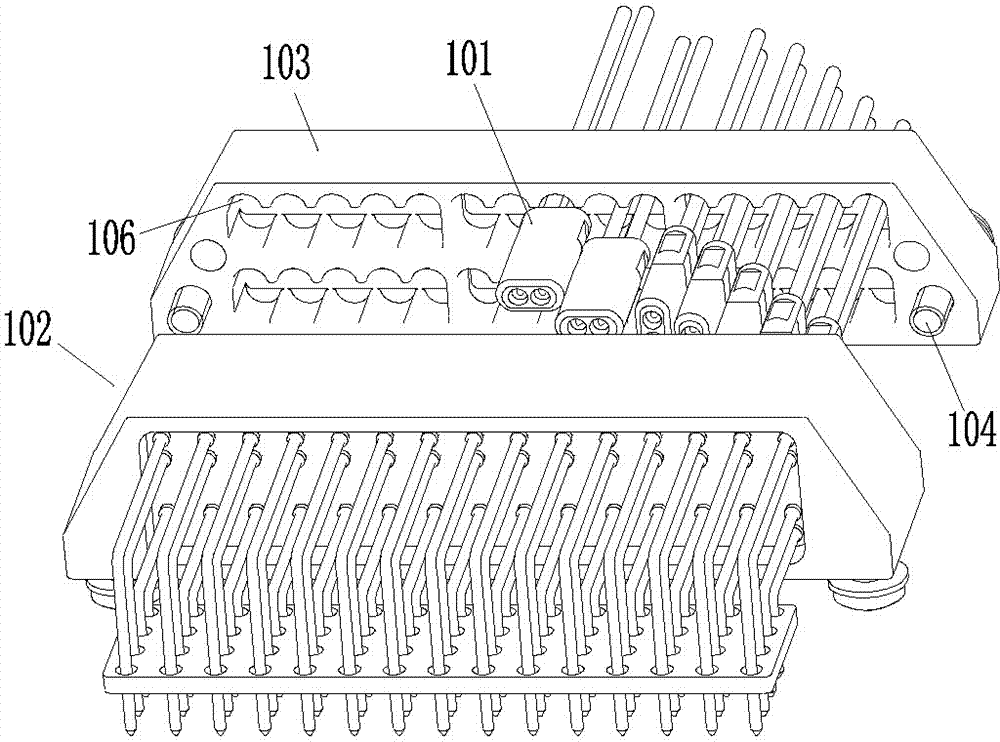

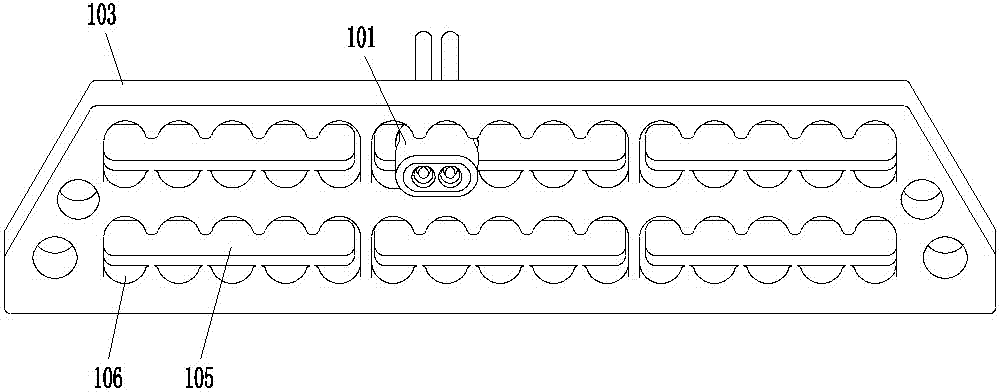

[0022] Examples of low volume electrical connector assemblies, such as Figure 1-3 As shown, it includes a plug 101 and a socket. In this embodiment, there are several plugs 101 and they are matched with the socket 102. The matching of the plug 101 and the socket 102 here means that each plug can find a matching plug on the socket. Each plug can be mated with the socket at the same time.

[0023] The plug 101 uses the front end as the plug-in end, which includes a plug shell, which is in the shape of a cuboid and has a backstop. The so-called backstop is a structure that cooperates with the socket 102 to prevent the plug from being automatically disengaged relative to the socket. In an example, the stop portion of the plug 101 is formed by its rear end surface.

[0024] The socket 102 uses the front end as the plug-in end, which has a socket shell, and a pressure plate 103 is fixedly mounted on the plug-in end of the socket shell, and the pressure plate 103 is detachably moun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com