Chain-type pin wheel transmission device

A transmission device and pin wheel technology, which is applied in the direction of transmission device, friction transmission device, belt/chain/gear, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

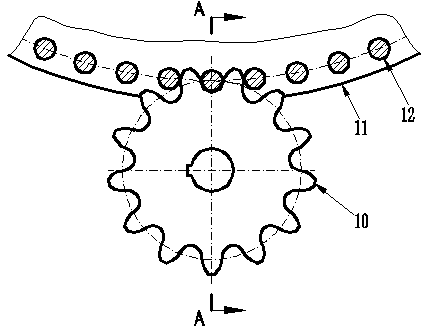

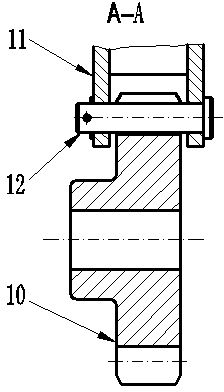

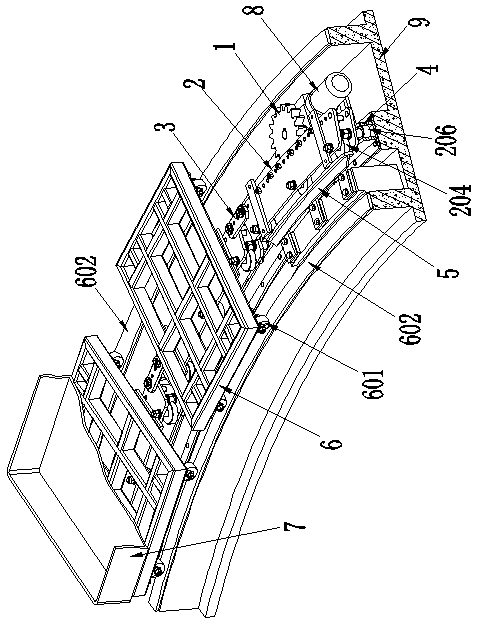

[0133] A chain pin wheel drive (see Figure 3 ~ Figure 5 ), which includes a chain pin wheel and a gear 1, and a guide device 4; the chain pin wheel is composed of 37 pin wheel units; each pin wheel unit is sequentially connected in series, and the specific connection method is hinged; each pin wheel hinged in series The unit is arranged along the gourd-shaped running path E provided by the guide device 4 to form a chain pin wheel (see Figure 10 , Figure 11 ).

[0134] The chain pin wheel is also specifically provided with a transmission pin 201 fixed on the pin wheel unit for meshing with the gear 1, and the distance between every two adjacent transmission pins 201 in the chain pin wheel is equal and together constitutes The gear teeth of the chain pin wheel; the gear 1 forms a multi-section movable pin tooth transmission structure through the transmission pin 201 and the chain pin wheel.

[0135] Present embodiment also comprises following preferred content:

[0136] I...

Embodiment 2

[0184] This embodiment is mostly the same as Embodiment 1, the difference is:

[0185] 1. A chain type pin wheel transmission device, the chain type pin wheel is composed of 10 pin wheel units; the series hinged pin wheel units are arranged along the closed elliptical running path E provided by the guide device 4 to form a chain type pin wheel (see Figure 9 );

[0186] 2. The main rack 2 and the short rack 3 of the pin wheel unit meet the following requirements:

[0187] The length ratio of the main tooth span M to the short tooth span N, that is, M / N, is 6; the two adjacent main racks 2 can swing relative to each other, and the range of the relative swing angle, that is, the swing angle β, is +27.6° ~+48.6°; the distribution line D of the transmission pin of the main rack 2, the distribution line U of the guide wheel and the distribution line H of the balance wheel are concentric arcs; the number of transmission pins 201 on the main rack 2 is 18, and the short rack 3. The ...

Embodiment 3

[0214] This embodiment is mostly the same as Embodiment 1, the difference is:

[0215] 1. A chain-type pin-wheel transmission device, the chain-type pin-wheel is composed of 200 pin-wheel units; the pin-wheel units hinged in series are arranged along the rectangular closed running path E provided by the guide device 4 to form a chain type pin wheel (see Figure 12 ).

[0216] 2. Selection of the driving section F in the chain pin wheel drive:

[0217] The running path E of the chain-type pin wheel transmission device is composed of four straight lines and four circular arcs sequentially combined in series; the straight line and the circular arc in the path are connected tangentially to form a continuous running path E. This embodiment is based on The characteristics of the running path E, a driving section F is set in the middle of the four straight lines in the running path E, and the transmission type of the pin-rack meshing is adopted.

[0218] 3. The main rack 2 and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com