Heat radiating fan and power supply device

A heat dissipation fan and power supply device technology, which is applied in the direction of measuring devices, data processing power supplies, and electrical digital data processing, etc., can solve problems such as increasing air flow resistance, reducing air flow, and large circuit board changes, so as to improve work efficiency. The effect of improving quality, improving service life and saving internal space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The following descriptions of the various embodiments refer to the accompanying drawings to illustrate specific embodiments in which the present invention can be practiced. The directional terms mentioned in the present invention, such as "up", "down", "front", "back", "left", "right", "inside", "outside", "side", etc., are for reference only The orientation of the attached schema. Therefore, the directional terms used are used to illustrate and understand the present invention, but not to limit the present invention.

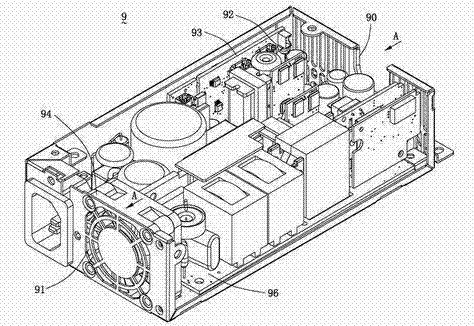

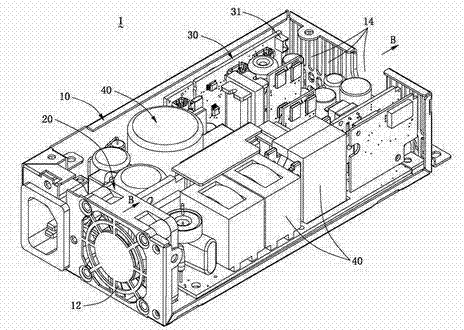

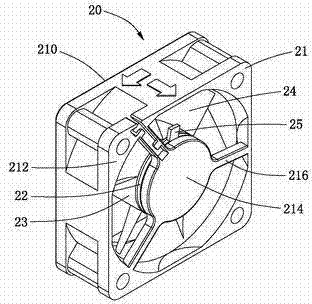

[0048] Please refer to figure 2 As shown, it shows the internal structure of one embodiment of the power supply device 1 of the present invention and the wind flow direction B inside the power supply device 1 . The power supply device 1 of the present invention includes an outer casing 10 , a cooling fan 20 installed in the outer casing 10 , a control circuit board 30 installed in the outer casing 10 , and a plurality of electronic components 40 . Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com