Super-heated steam meat food baking machine

A technology of superheated steam and meat food, applied in food ovens, baking, food science and other directions, can solve the problems of not maximizing the retention of meat nutritional value, easily destroying meat protein components, and long baking time. , to achieve the effect of simple structure, fast speed and sufficient heating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

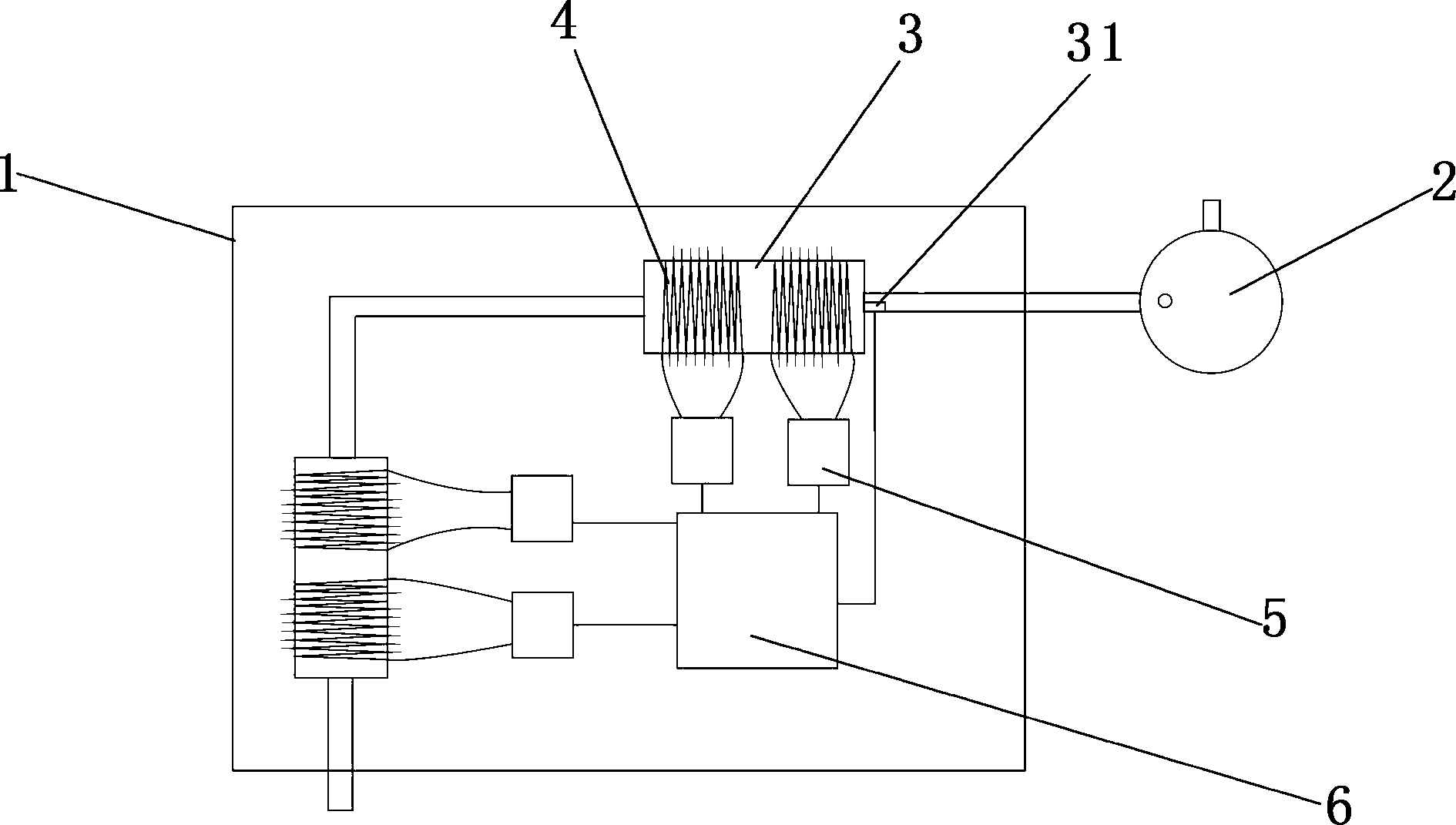

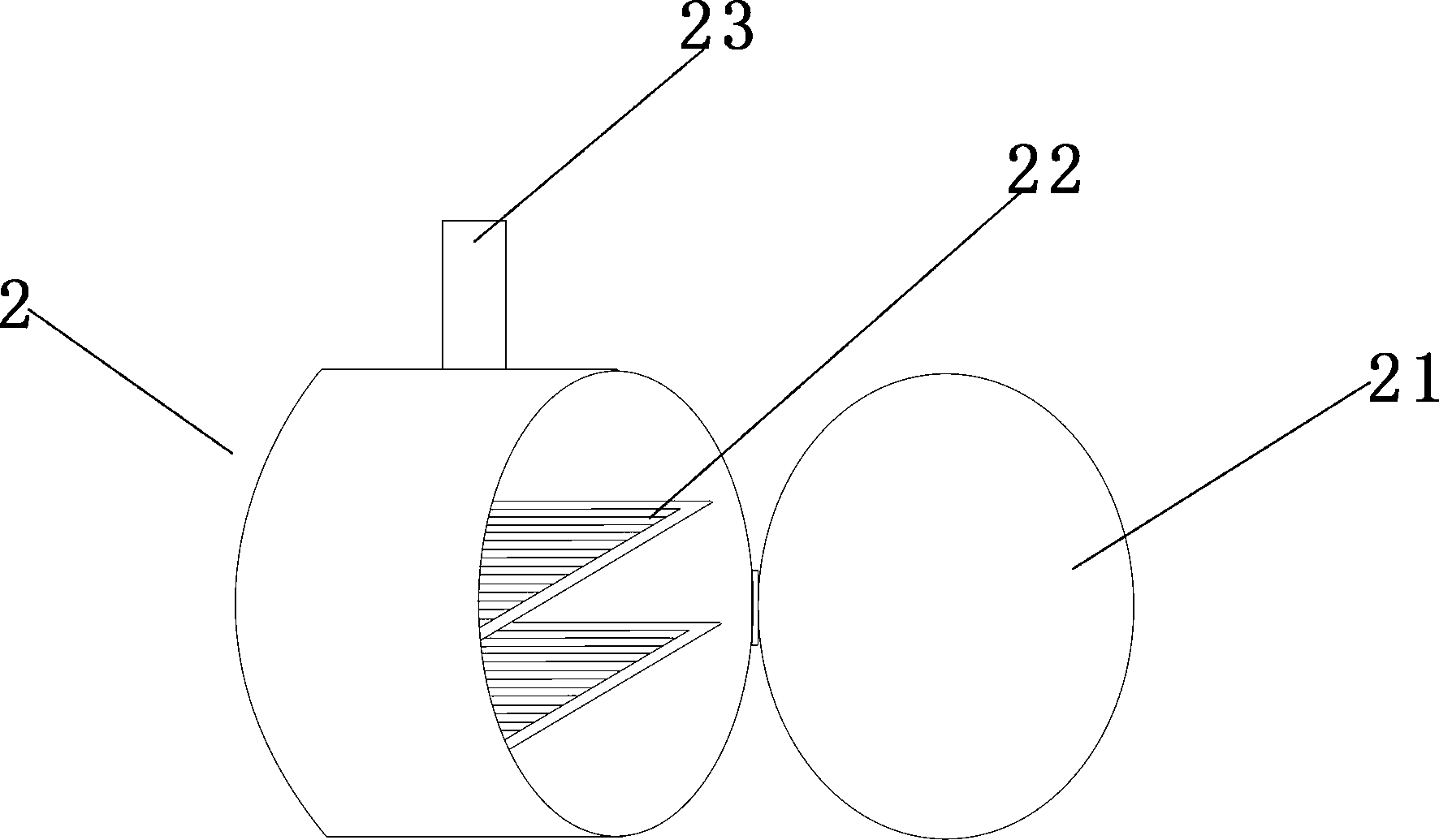

[0010] Such as figure 1 , figure 2 As shown, a superheated steam meat roasting machine includes a box body 1, a superheated steam generator installed inside the box body 1, and an oven 2 connected to the steam output end of the steam generator, and is characterized in that: The superheated steam generator is composed of two electromagnetic induction heating cylinders 3 in series. The electromagnetic induction heating cylinder 3 is cylindrical. Two sets of coils 4 are wound on the outside of the cylinder wall, and the coils are each connected to the corresponding high-frequency generator 5. , The high-frequency generator 5 is connected to the PLC controller 6; the oven 2 has a cylindrical barrel structure, and the steam output pipe of the superheated steam generator is connected to the circumferential wall of the oven 2. A door 21 that can be opened and closed is arranged on the bottom surface, a grill 22 for placing meat is arranged in the oven, and an exhaust hole 23 is opene...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com