Temperature control device for sending mold

A temperature control device and mold technology, applied in temperature control, measuring device, optical radiation measurement, etc., can solve the problem that the temperature sensing element cannot truly reflect the actual temperature of the mold, and achieve accurate mold temperature, rapid heating, and accurate measurement Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

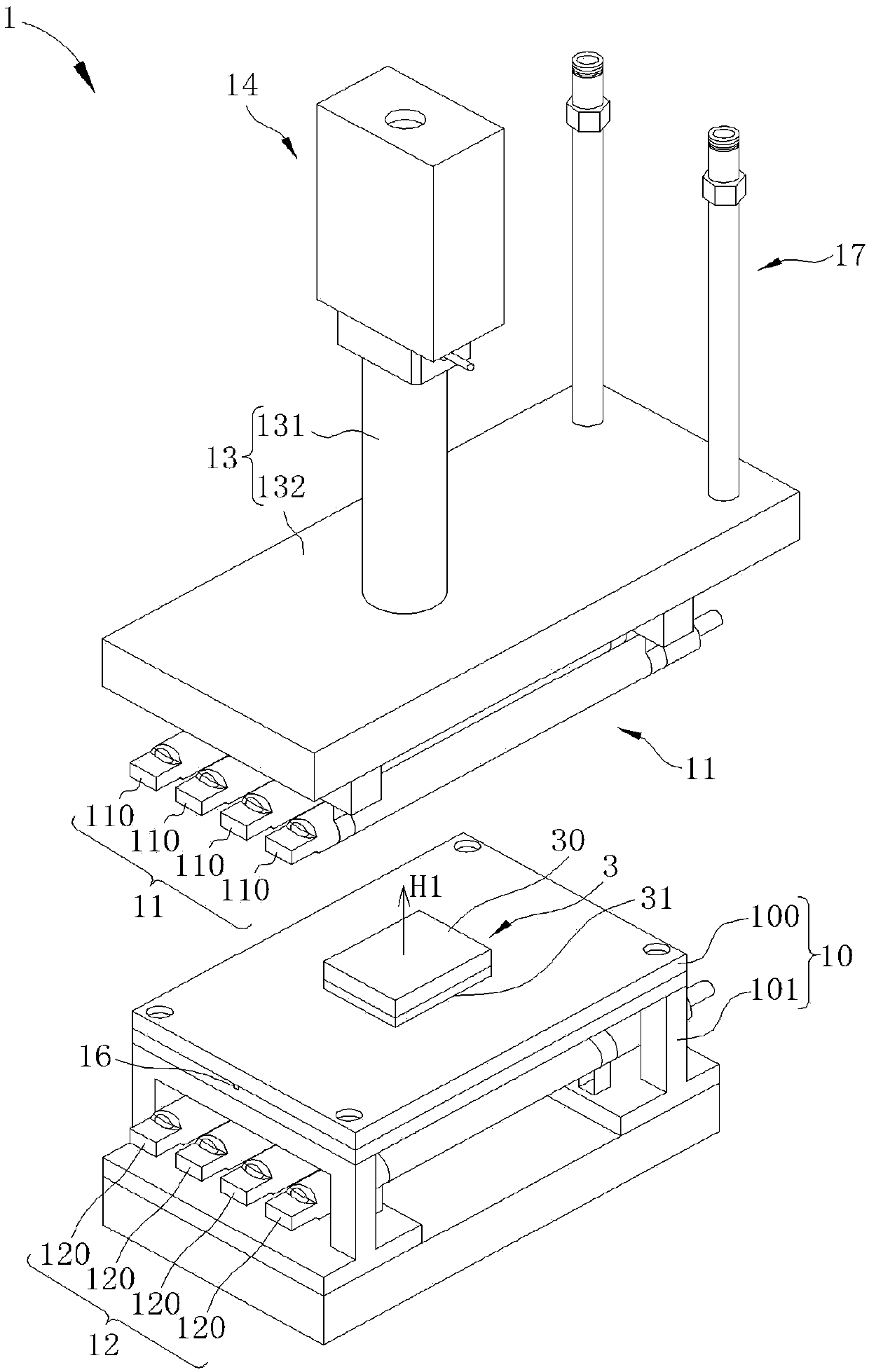

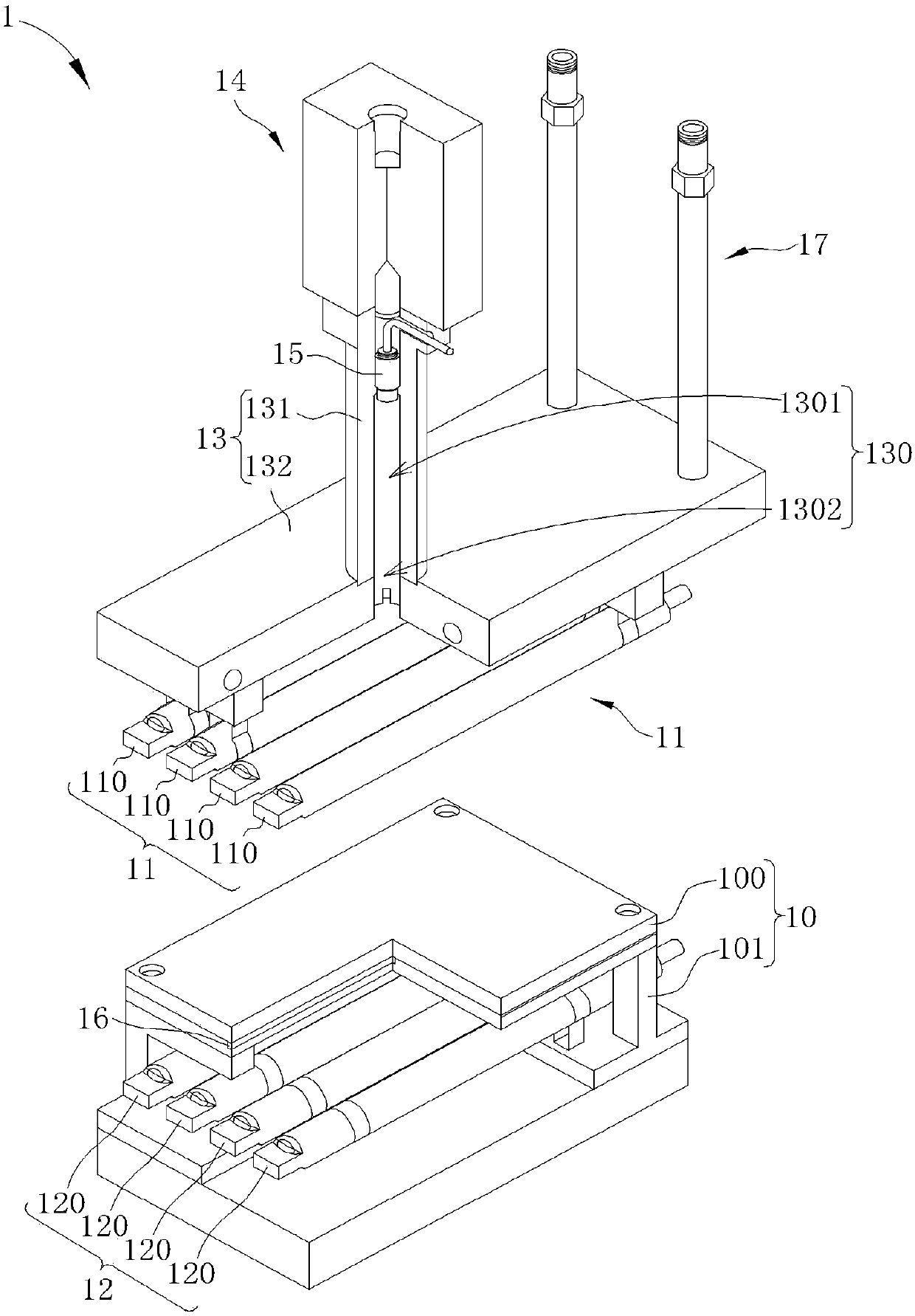

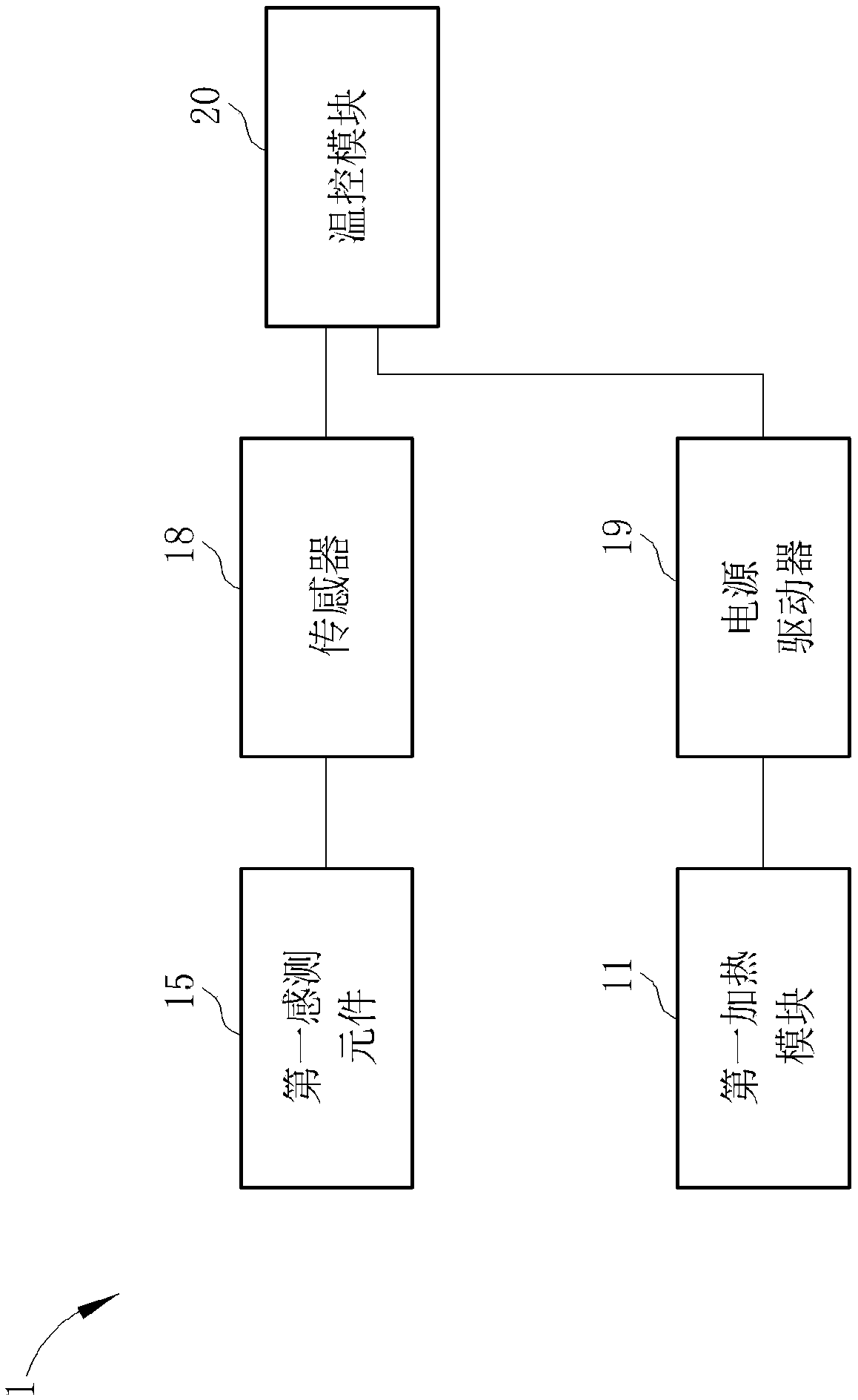

[0053] see Figure 1 to Figure 3 , figure 1 It is a schematic diagram of the appearance of the temperature control device 1 of the first embodiment of the present invention, figure 2 It is a partial sectional view of the temperature control device 1 according to the first embodiment of the present invention, image 3 It is a functional block diagram of the temperature control device 1 according to the first embodiment of the present invention. Such as Figure 1 to Figure 3 As shown, the temperature control device 1 includes a base 10, a first heating module 11, a second heating module 12, a fixing mechanism 13, an adjustment seat 14, a first sensing element 15, a second sensing element 16 . A cooling water circuit 17 , a sensor 18 , a power driver 19 and a temperature control module 20 .

[0054] The base 10 is used to support a mold 3, the first heating module 11 is arranged above the base 10 and spaced apart from the mold 3, the first heating module 11 heats an upper si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com