Central distribution quantitative filling machine

A filling machine and rack technology, which is applied in the field of central distribution and quantitative filling machines, can solve the problems that the output of materials cannot be effectively controlled, the disassembly and assembly are inconvenient, and the structure of the filling valve is complicated, so as to facilitate thorough cleaning. , Simple structure, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

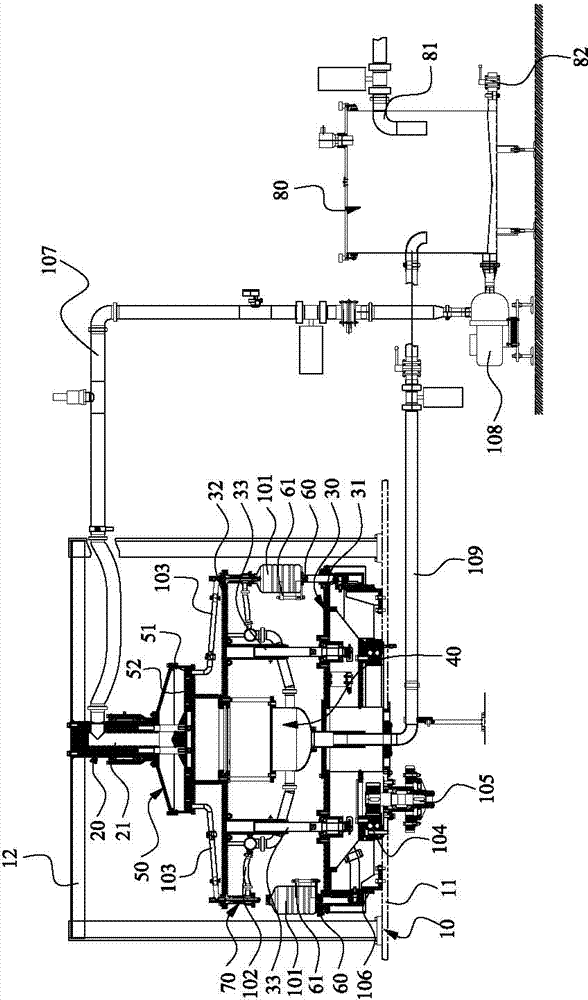

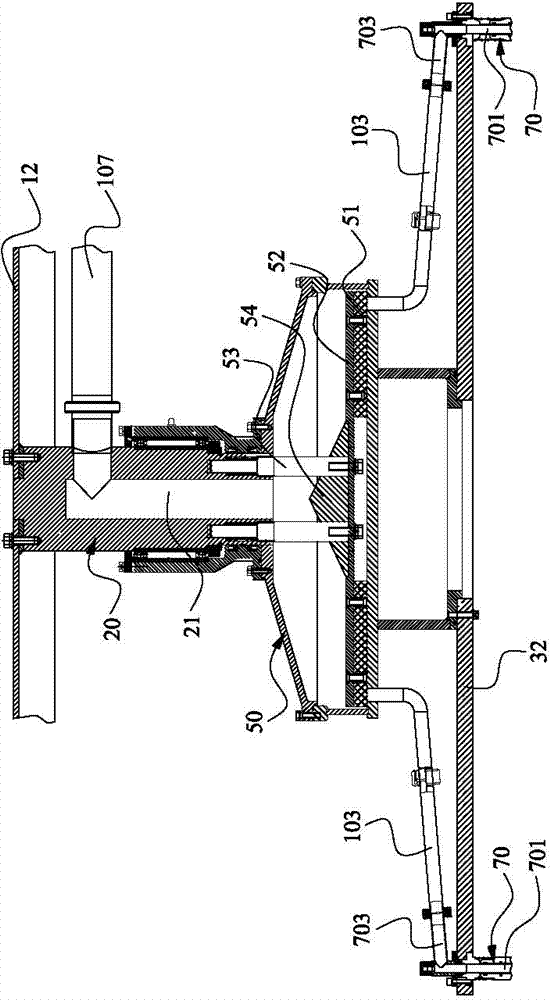

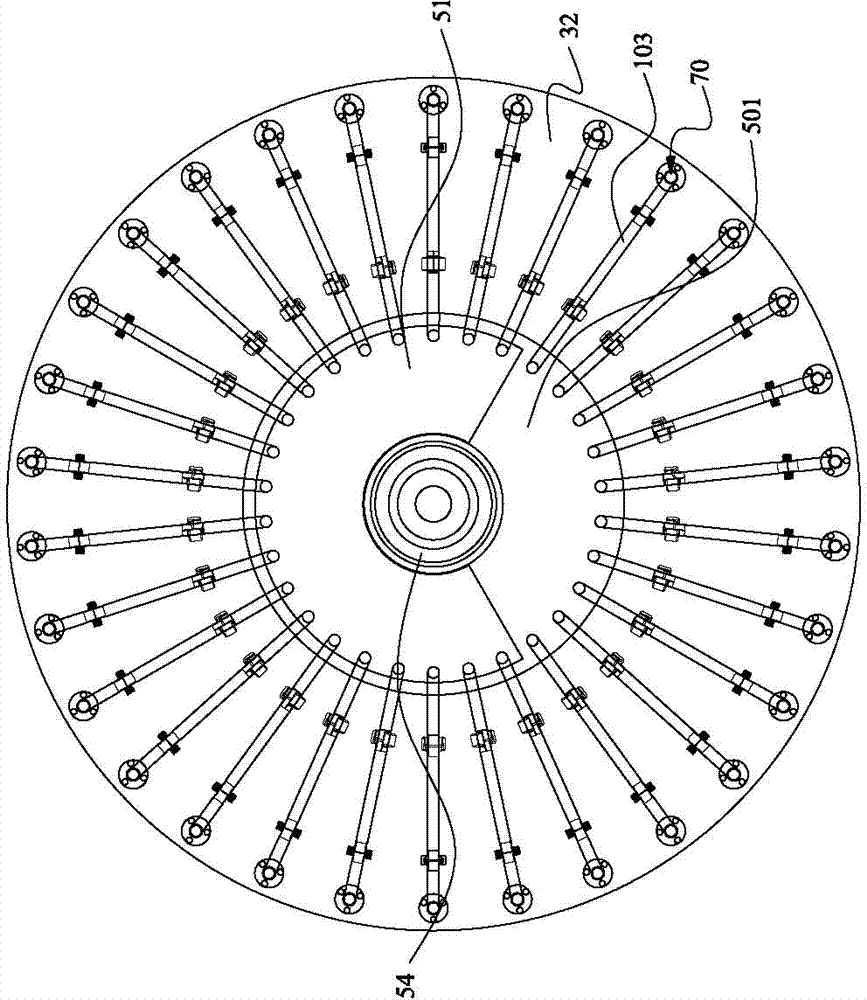

[0055] Please refer to Figure 1 to Figure 5 As shown, it shows the specific structure of the preferred embodiment of the present invention, including a frame 10, a rotating assembly 30 rotatably arranged on the frame 10, a return cylinder 40 arranged on the rotating assembly 30, and a The material cylinder 50 rotatably installed on the rotating assembly 30 and rotates synchronously with the rotating assembly 30 and the mandrel 20 supported on the return cylinder 40 and fixed on the frame 10 at the same time.

[0056] Wherein, the frame 10 includes a platform 11 and an anti-rotation frame 12 erected on the platform 11, the mandrel 20 is vertically fixed on the anti-rotation frame 12, and the anti-rotation frame 12 consists of a horizontal frame and two vertical The two ends of the horizontal frame are connected with two vertical columns by bolts. There are long holes in the two vertical columns at the joint. After loosening the bolts, the horizontal frame can be adjusted up an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com