Production process of novel fuel and fabrication method of system device for producing novel fuel

A technology of system device and production process, which is applied in the field of fuel production process and system equipment, can solve the problems of low power consumption and low noise, and achieve the effect of low power consumption and low noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

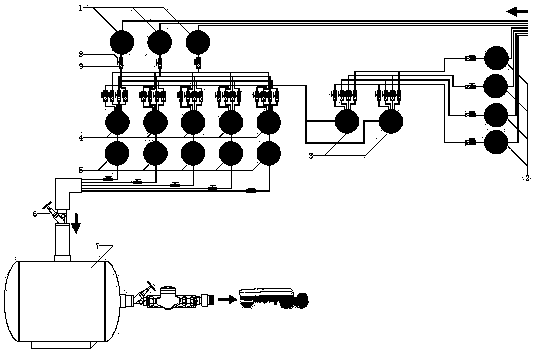

[0013] figure 1 The situation of the system device of the present invention is shown, as for the use of fuel production enterprises, at first the raw materials in the raw material tanks 1 and 2 are prepared sufficiently through the raw material delivery pipes, and all corresponding control valves 8 and electronic flowmeters 9 are opened simultaneously , and then make the raw materials enter the corresponding emulsification homogeneous stirring equipment 3, mixing tank 4 and emulsification homogeneous stirring equipment 5, and carry out primary to final object dispersion, emulsification, homogenization and other treatments, and the finished oil after homogenization treatment is controlled The valve 6 is sent to the refined oil storage tank 7 for use.

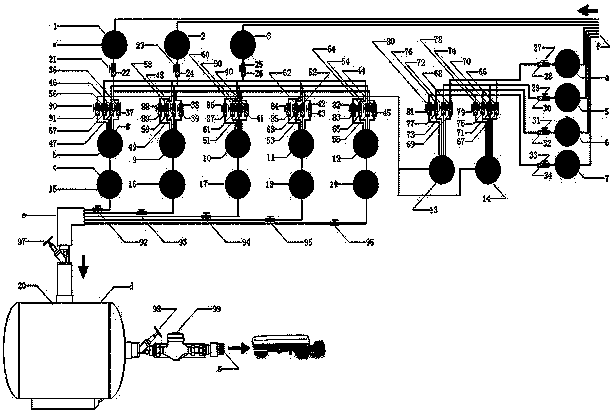

[0014] figure 2Among them, the system device is composed of raw material tank a, mixing tank b, emulsification homogeneous stirring equipment c, refined oil storage tank d and oil delivery system e, raw material tank a, mixing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com