Three-closed-loop control method for DC electronic load limiting rail voltage

A technology of DC electronic load and electronic load, which is applied in the direction of control/regulation system, adjustment of electrical variables, instruments, etc., and can solve problems such as large impact, stray current, and electric sparks in the DC traction power supply system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

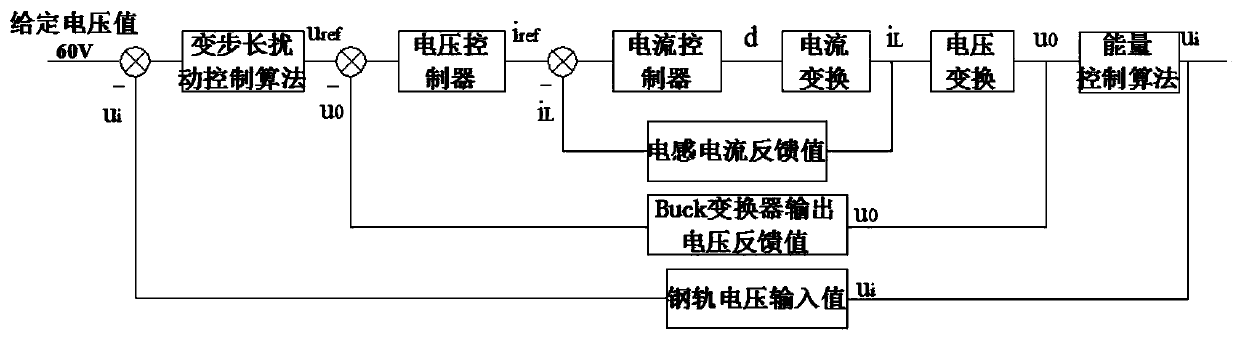

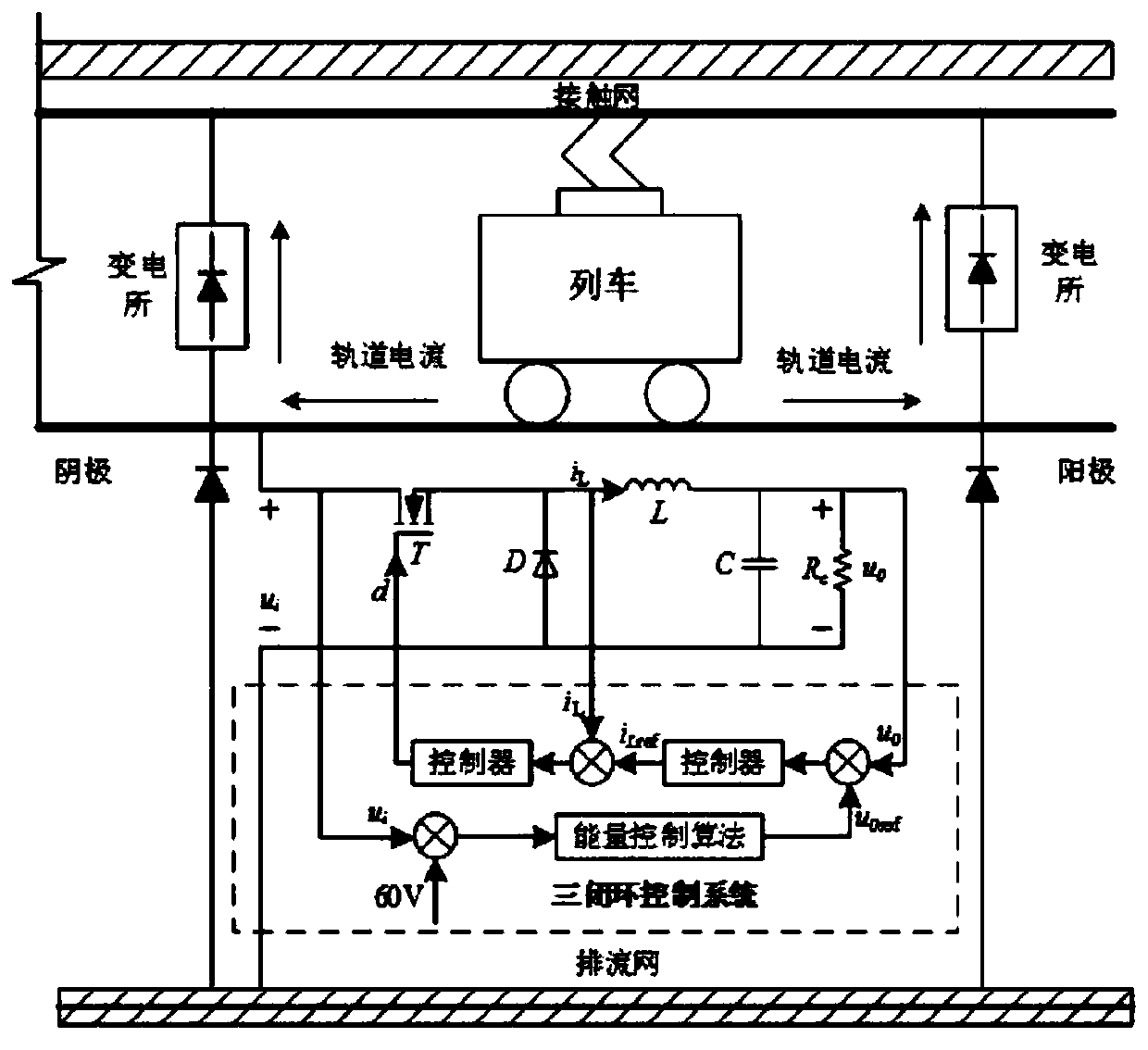

[0057] A three-closed-loop control method for DC electronic loads with rail voltage limitation, the specific steps are as follows:

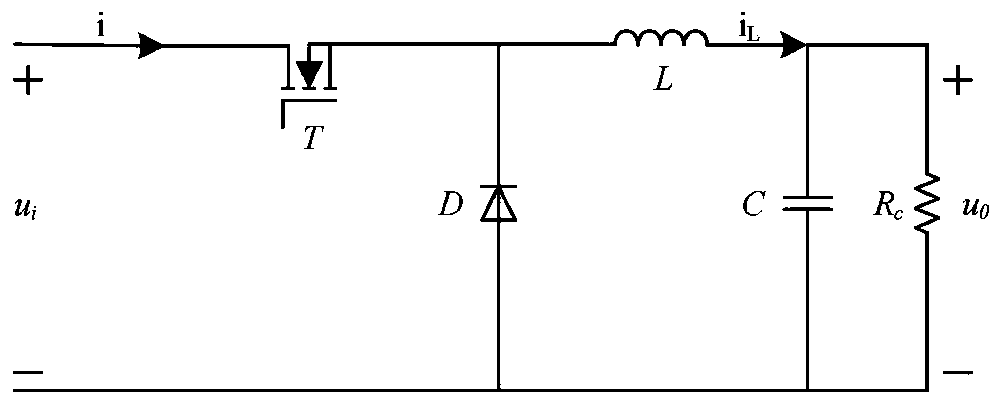

[0058] Step 1: Use the state-space averaging method to perform small-signal modeling on the Buck converter to obtain a small-signal model. The specific formula is as follows:

[0059]

[0060] Perform a pull transformation on the small-signal model to obtain the input-to-output transfer function:

[0061]

[0062]

[0063] Step 2: Establish the traditional double closed-loop control system of the Buck converter, the inner loop is the inductor current control loop, the outer loop is the output voltage control loop, and the parameters of the PI regulator are determined.

[0064] Step 3: Sampling the rail voltage and comparing it with the set safe voltage value of 60V to determine the working status of the electronic load device.

[0065] Step 4: Use a fixed step size ΔU to disturb the terminal reference voltage, and add the disturbance to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com