Elevator system

An elevator system and elevator car technology, which is applied to elevators, textile cables, transportation and packaging in buildings, etc., can solve the problems of increasing the height and size of the lift passage, and achieve the effect of reducing the height size and reducing the cross-sectional area of the passage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

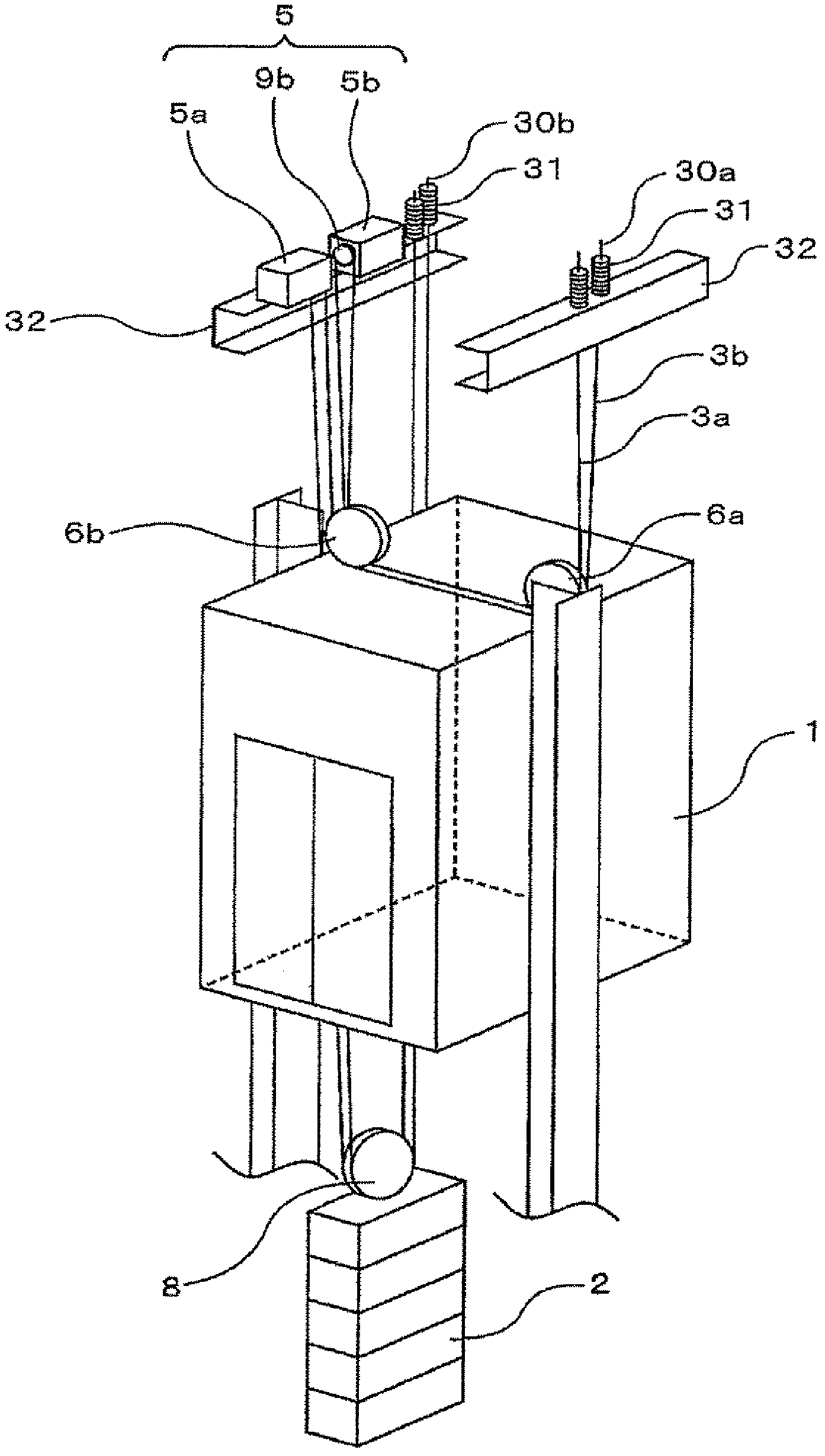

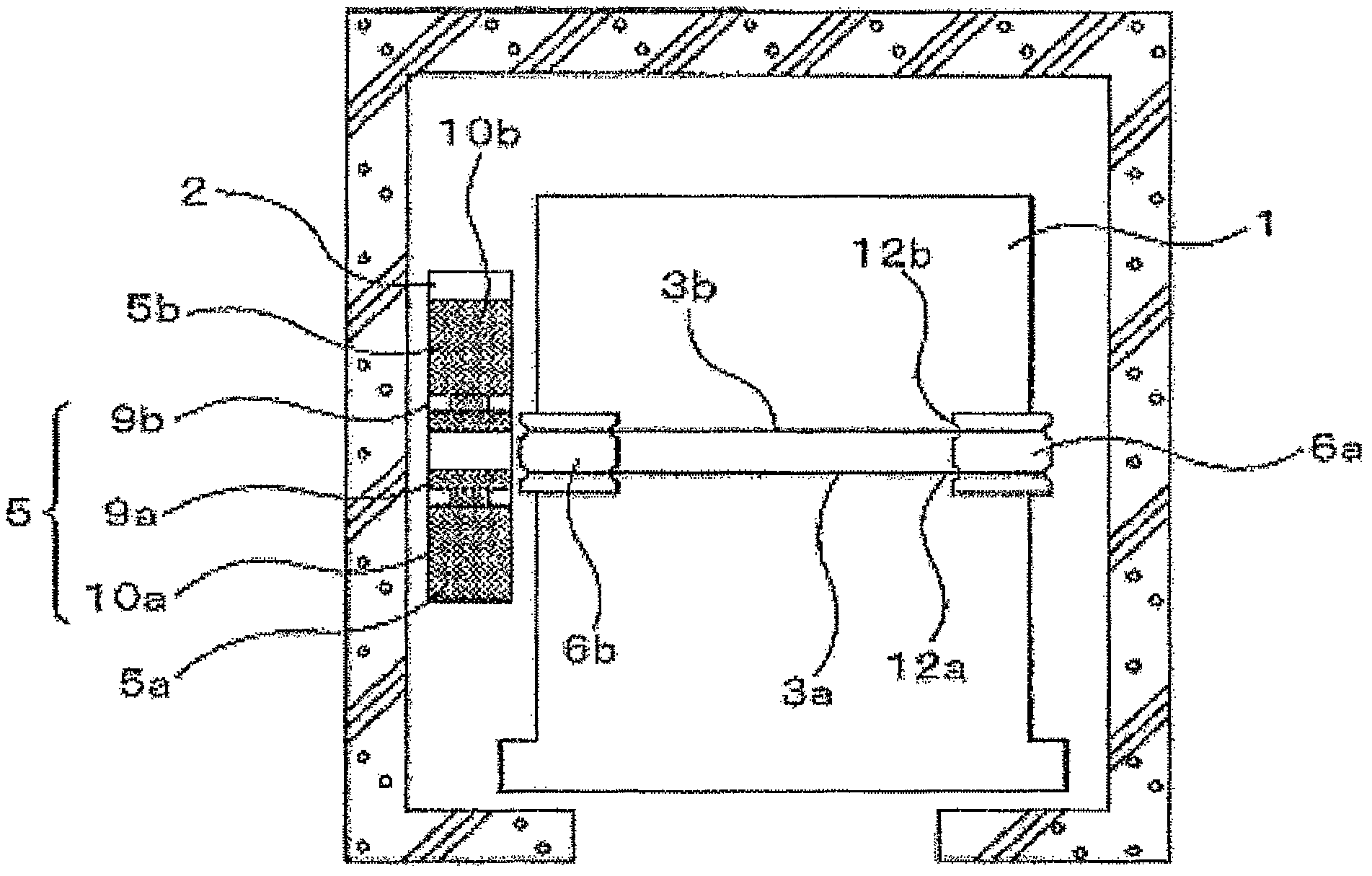

[0036] Hereinafter, the configuration of an elevator according to an embodiment of the present invention will be described with reference to the drawings. First refer to figure 1 and figure 2 Give a rough explanation.

[0037] In a general elevator, the main rope 3 is used to connect the elevator car 1 and the counterweight 2, and the hoist 5 is installed in the middle of the main rope 3, and the main rope is hoisted by the hoist 5, and the hoist The action causes the elevator car 1 and the counterweight 2 to go up and down in opposite directions.

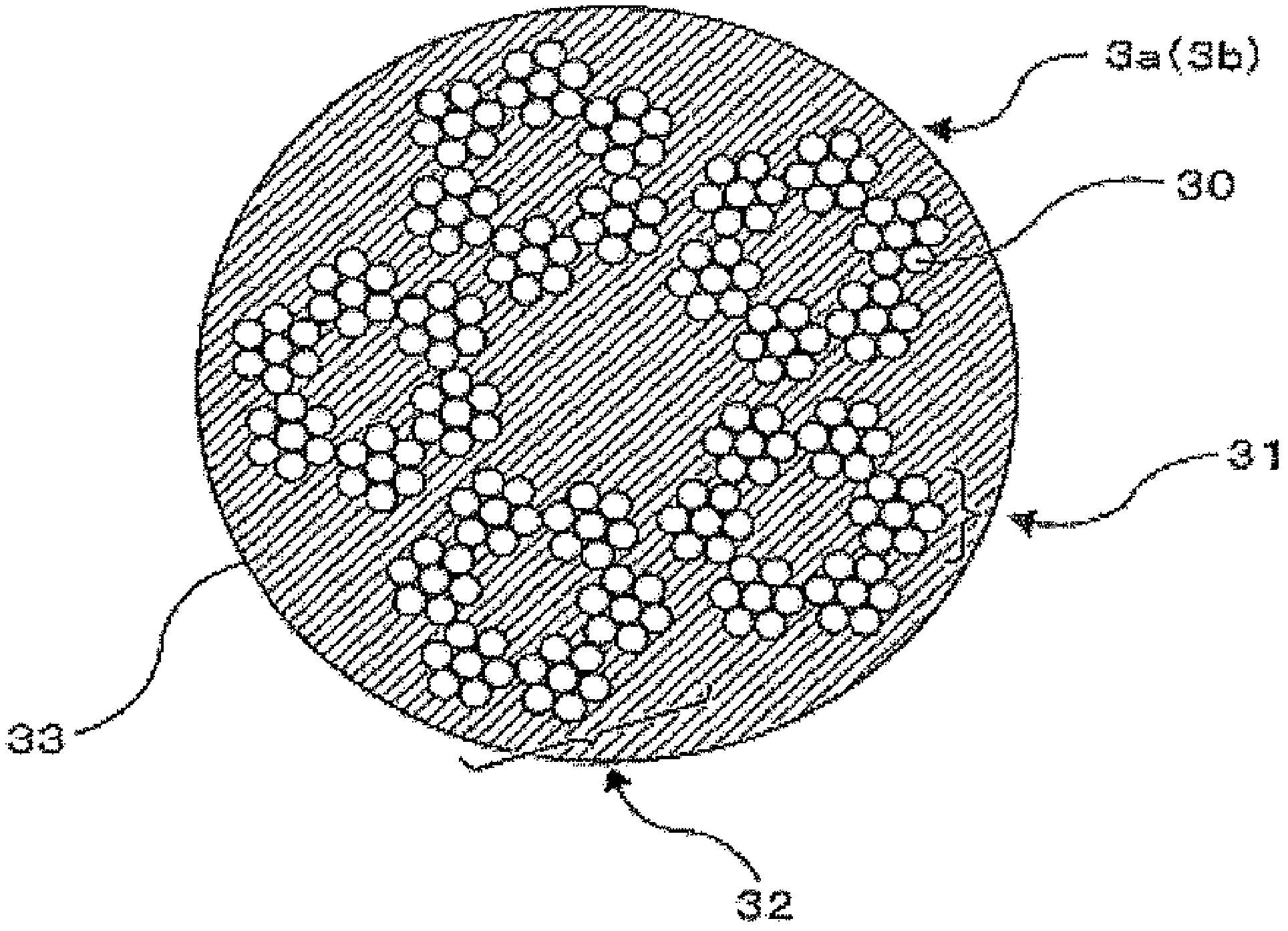

[0038] The main sling 3 of this embodiment uses two pairs of main slings, and a spring 31 for tension adjustment is provided at one end 30a of the main sling 3, and is suspended on a beam 32 fixed to the wall of the hoistway. In addition, the other end 30b of the main sling 3 is also provided with a spring 31 for tension adjustment, and is similarly suspended on a beam 32 fixed to the wall of the hoistway.

[0039] The top of ...

no. 2 example

[0076] Refer to the following Figure 4 Elevators according to other embodiments of the present invention will be described in detail. and figure 2 The embodiment shown differs in that in this embodiment the pulleys 6a and 6b of the pulleys 6 arranged at the top of the elevator car 1 form a set, and another set of pulleys is arranged at a distance That is, pulley 6c and pulley 6d.

[0077]Moreover, the sheave 9a and the sheave 9b of the hoisting machine 5a and the hoisting machine 5b are also installed in the beam 32 so that it may be spaced apart according to this predetermined distance.

[0078] The main rope 3a passes through the pulley 6a and the pulley 6b, the main rope 3b passes through the pulley 6c and the pulley 6d, and the main rope 3a and the main rope 3b are wound on the hoisting machine 5a and the sheave 9a and the sheave 9b of the hoisting machine 5b.

[0079] According to the above structure, the distance between the main rope 3a and the main rope 3b can be ...

no. 3 example

[0082] Refer to the following Figure 5 and Image 6 An installation example of the hoist 5a and the hoist 5b at the upper portion of the hoistway according to yet another embodiment of the present invention will be described.

[0083] exist Figure 1 to Figure 3 In the illustrated embodiment, the hoist 5a and the hoist 5b are fixed to the beam 32 in a state facing each other, so that the axial lengths of the hoist 5a and the hoist 5b are added together, so that the horizontal length of the hoist 5 becomes longer.

[0084] In contrast, the present embodiment is characterized in that a structure for reducing the lateral length (axial length) of the hoist 5 is proposed. In order to shorten the overall axial length L of the hoist 5, the hoist 5a and the hoist 5b are arranged as Overlap in the height direction.

[0085] Two hoisting machines, that is, hoisting machine 5a and hoisting machine 5b, are arranged to be staggered by a specified amount in the motor axial direction, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com