Microcrystalline ceramic composite electrothermal material and method for preparing far-infrared ceramic electrothermal plate by using same

A technology of far-infrared ceramics and electric heating materials, applied in the field of high-performance electric heating materials and the production of far-infrared ceramic electric heating plates with this material, can solve the problems of poor electrical insulation performance, short working life, unstable electrical parameters, etc., and achieve insulation Good performance and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

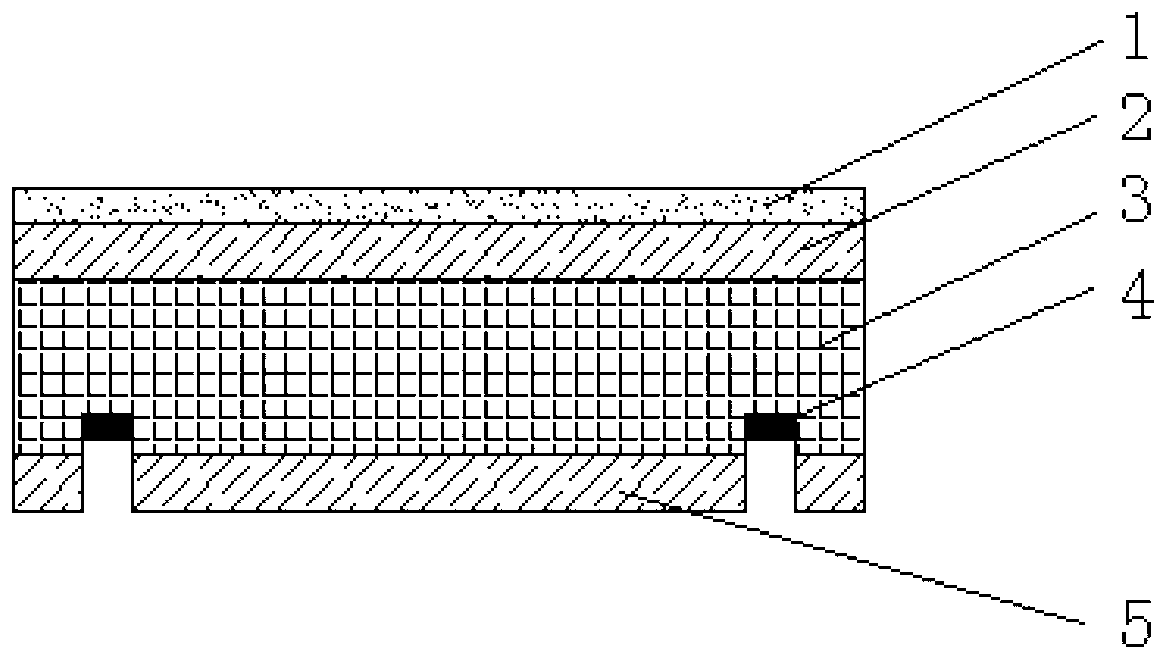

Image

Examples

specific Embodiment approach 1

[0023] In this embodiment, the microcrystalline ceramic composite electric heating material is composed of graphite microcrystals with a particle size of 30-50 μm, accounting for 59.5% of the total weight, and destatic graphitized carbon crystals accounting for 0.5% of the total weight, accounting for 40% of the total weight. Carbon SiC-B 4 C composite powder forms a solid phase mixture, and then mixes it with water and polyacrylic acid sodium salt at a mass ratio of 100:35:0.5 to make a slurry, which is sanded and homogenized by a horizontal sand mill for 2 hours, and then dried Dry and pulverize to obtain a composite electric heating material. The described destatic graphitized carbon crystal is composed of polyacrylonitrile-based carbon fibers with a count of 12K and a diameter of 7 μm, cut into carbon fibers with a length of 3 to 6 mm, and graphite crystallites with a particle size of 1 to 2 μm by weight Mixed at a ratio of 20:1, and processed by ball milling into destati...

specific Embodiment approach 2

[0024] The difference between this embodiment and specific embodiment 1 is that the microcrystalline ceramic composite electrothermal material is composed of graphite microcrystals accounting for 40% of the total weight, destatic graphitized carbon crystals accounting for 1% of the total weight, accounting for 59% of the total weight SiC-B with excess carbon 4 C composite powder composition. Others are the same as the first embodiment.

specific Embodiment approach 3

[0025] The difference between this embodiment and specific embodiment 1 is that the microcrystalline ceramic composite electrothermal material is composed of graphite microcrystals accounting for 50% of the total weight, destatic graphitized carbon crystals accounting for 5% of the total weight, and 45% of the total weight. SiC-B with excess carbon 4 C composite powder composition. Others are the same as the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com