Method for improving 60 DEG C dynamic viscosity of pavement petroleum asphalt

A technology of road asphalt and dynamic viscosity, which is applied in the petroleum industry and hydrocarbon oil treatment, and can solve the problems of high production cost and complicated processing technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

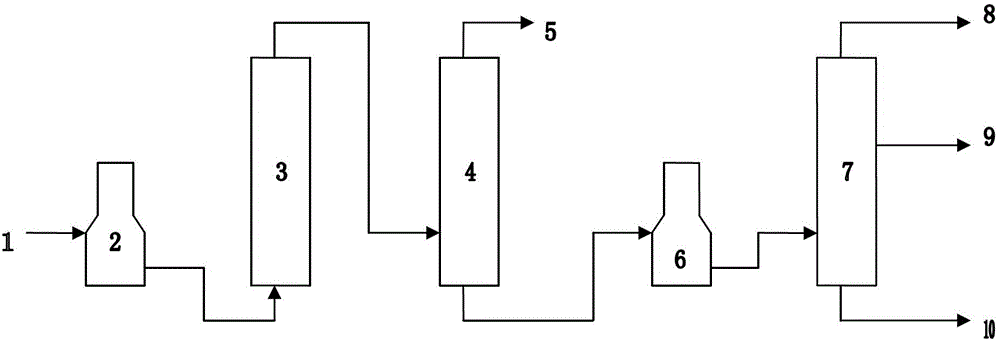

Method used

Image

Examples

Embodiment 1

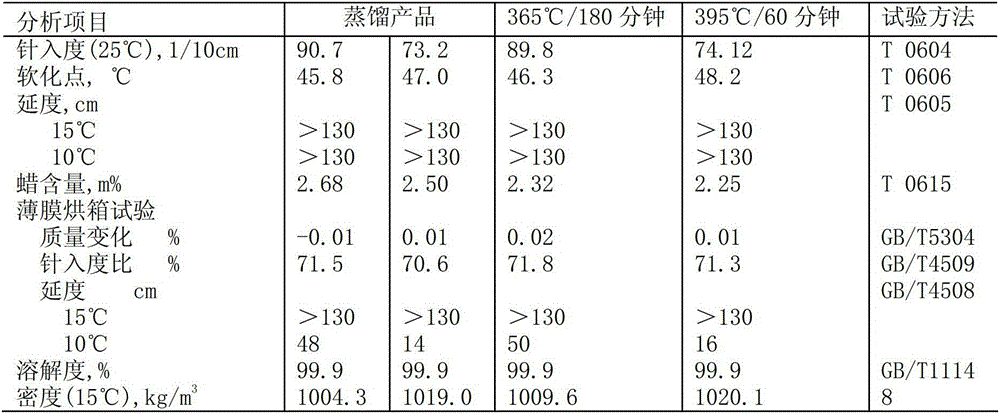

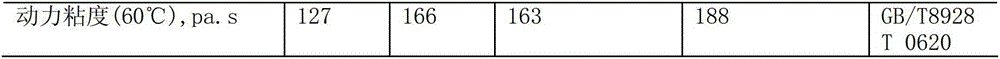

[0018] A low-condensation naphthenic crude oil and a heavy oil (mass mixing ratio 3:1) obtained by vacuum distillation of 90% # 、70 # The dynamic viscosities of asphalt at 60°C are 127 and 166pa.s respectively, and the vacuum residue of the mixed crude oil is used as raw material, and the reaction is carried out under the conditions of 365°C / residence time of 180 minutes and 395°C / residence time of 60 minutes. The product obtained after flash distillation and vacuum fractionation 90 # 、70 # The dynamic viscosities of asphalt at 60°C increased to 163 and 188 pa.s respectively.

Embodiment 2

[0020] A kind of naphthene-intermediate base crude oil obtains through vacuum distillation 90 # The dynamic viscosity of asphalt at 60°C is 97pa.s. Using the atmospheric residue of the crude oil as raw material, the temperature of 370°C / residence time is 160 minutes, 400°C / residence time is 100 minutes, and 410°C / residence time is 60 minutes The reaction product under the conditions obtained after normal pressure fractionation and vacuum fractionation 90 # The dynamic viscosities of asphalt at 60°C increased to 155, 166, and 161pa.s, respectively.

Embodiment 3

[0022] Another naphthene-intermediate base crude oil obtained by vacuum distillation # The dynamic viscosity of asphalt at 60°C is 130pa.s. Using the atmospheric residue of the crude oil as raw material, the temperature is 360°C / residence time of 200 minutes, 385°C / residence time of 70 minutes, and 410°C / residence time of 40 minutes. The reaction product under the condition of the 90 # The dynamic viscosities of asphalt at 60°C increased to 161, 159, and 168 pa.s, respectively.

[0023] Example 1

[0024]

[0025]

[0026] Example 2

[0027]

[0028] Example 3

[0029]

[0030]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com