Composite vacuum glass with built-in shutters, and use method of composite vacuum glass

A technology of vacuum glass and shutters, applied in the direction of windows/doors, door/window protection devices, building components, etc., can solve the problems of unsatisfactory heat insulation effect and inability to adjust, and achieve good sound insulation effect, good sound insulation, and good heat insulation. effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

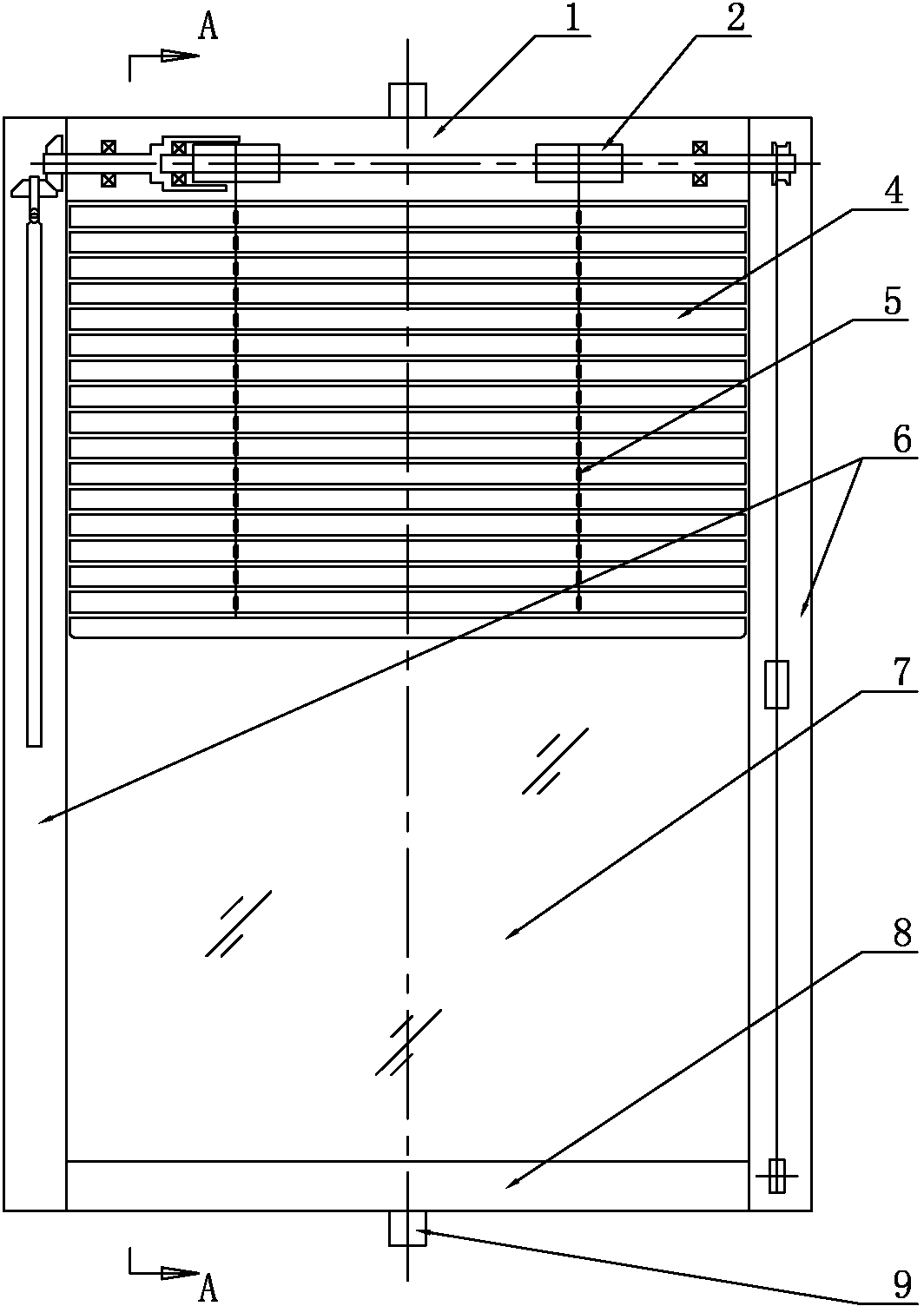

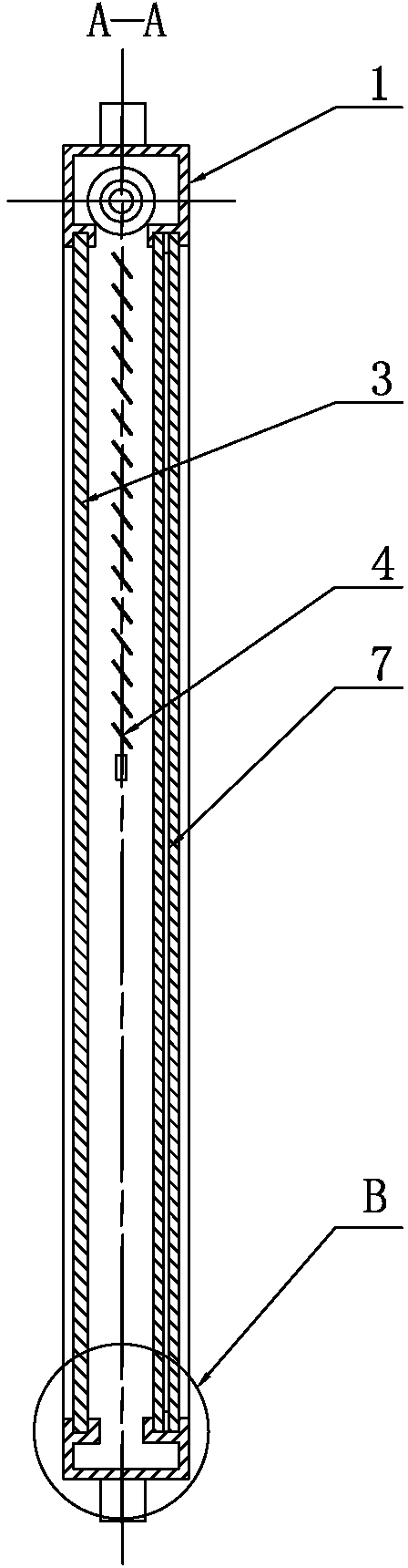

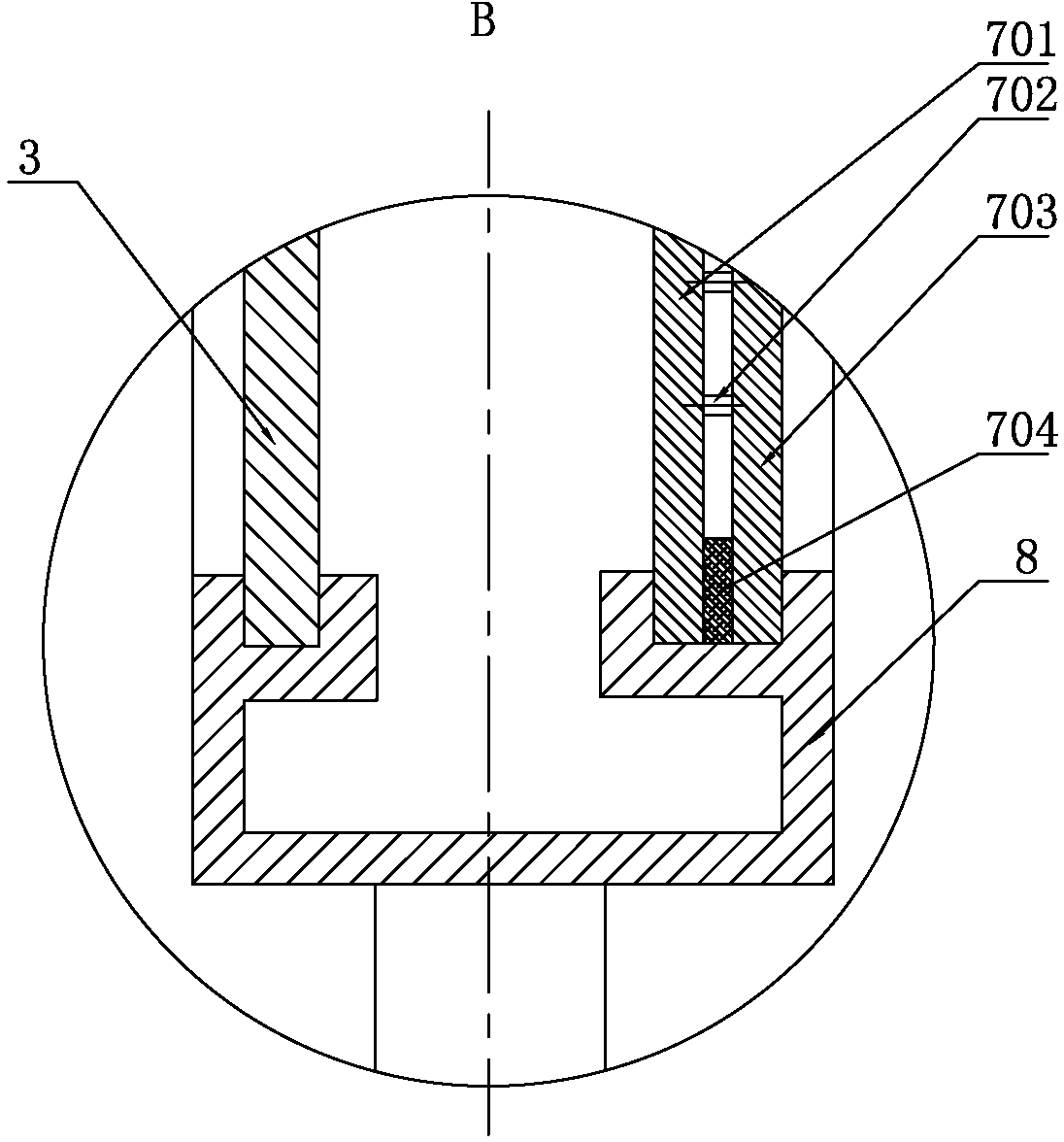

[0012] Such as Figure 1-3 As shown, it is a composite vacuum glass with built-in louvers, which includes a window frame surrounded by an upper frame 1, a bottom frame and two side frames 6. Two glass lines are arranged in parallel in the window frame, and a louver 4 is arranged between the two glass lines. , the upper frame 1 is provided with a winding mechanism 2 connected to each blade of the shutter 4 through a suspension rope 5, one of the two glasses is a vacuum glass 7, and the other is an ordinary flat glass 3, and the vacuum glass 7 includes an outer layer Glass 703 and inner layer glass 701, between the outer layer glass 703 and inner layer glass 701 is a vacuum chamber, in the vacuum chamber, several support columns 702 are arranged between the outer layer glass 703 and the inner layer glass 701, the outer layer glass 703 and the inner layer glass 701 The periphery of the layer glass 701 is sealed by edge sealing solder 704; the center of the upper frame 1 and the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com