Energy-storing type energy-saving alternating-current contactor

An AC contactor, energy storage technology, used in relays, electrical components, circuits, etc., can solve the problems that the control circuit cannot be energized for a long time, the use environment is limited, and it cannot be released.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

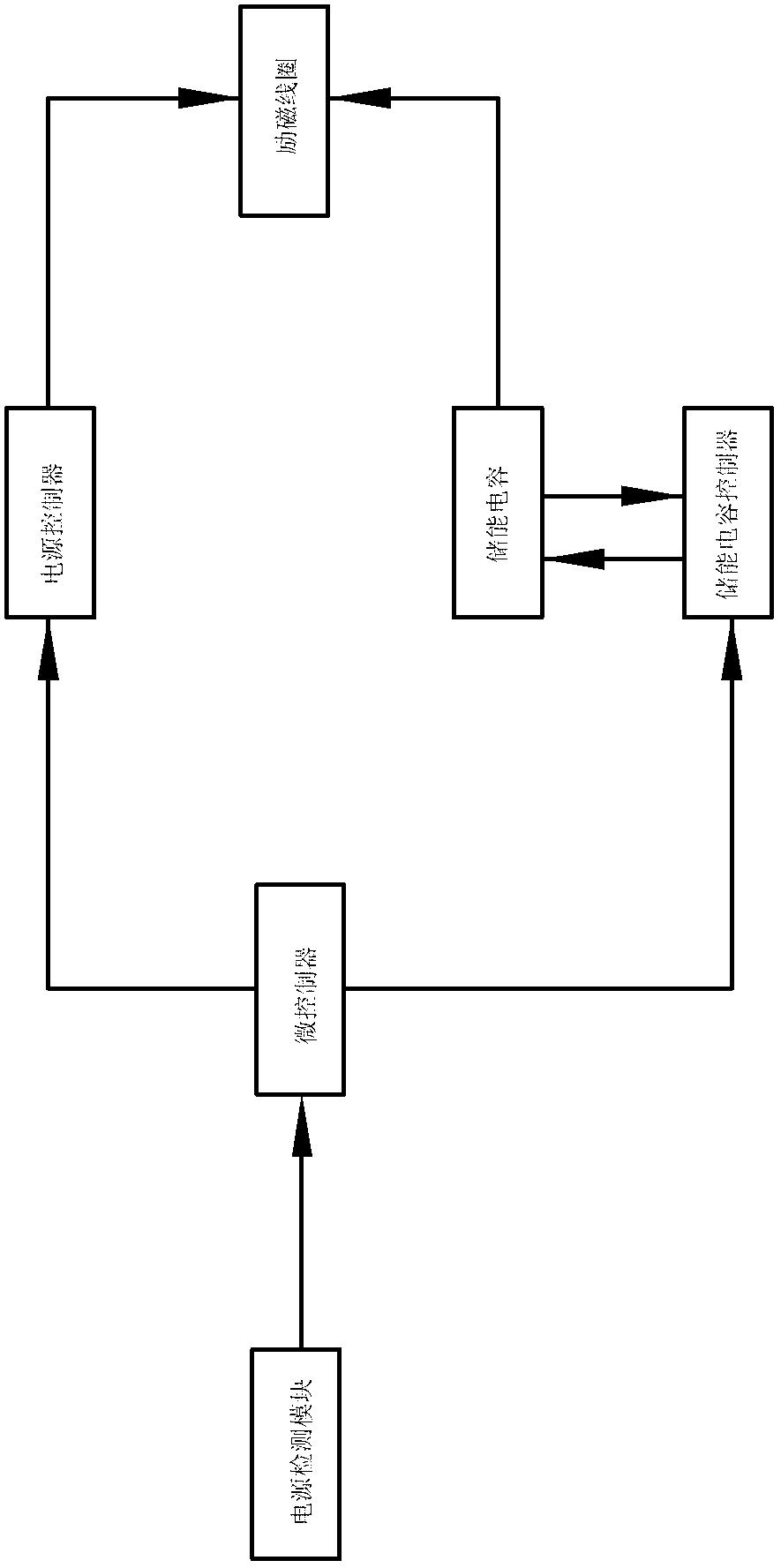

[0013] refer to figure 1 It can be seen that the output terminal of the power detection module is connected with the input terminal of the microcontroller, the output terminal of the microcontroller is connected with the power supply controller and the energy storage capacitor controller respectively, the output terminal of the power supply controller is connected with the excitation coil, and the energy storage capacitor The controller is connected to the energy storage capacitor, and the output terminal of the energy storage capacitor controller is connected to the exciting coil. After closing, the power supply is stopped, and the pull-in state is maintained by residual magnetism. When the power is cut off, the energy storage capacitor demagnetizes the excitation coil to achieve the purpose of release. During the whole process, only a little power is consumed, and the energy-saving effect is very obvious.

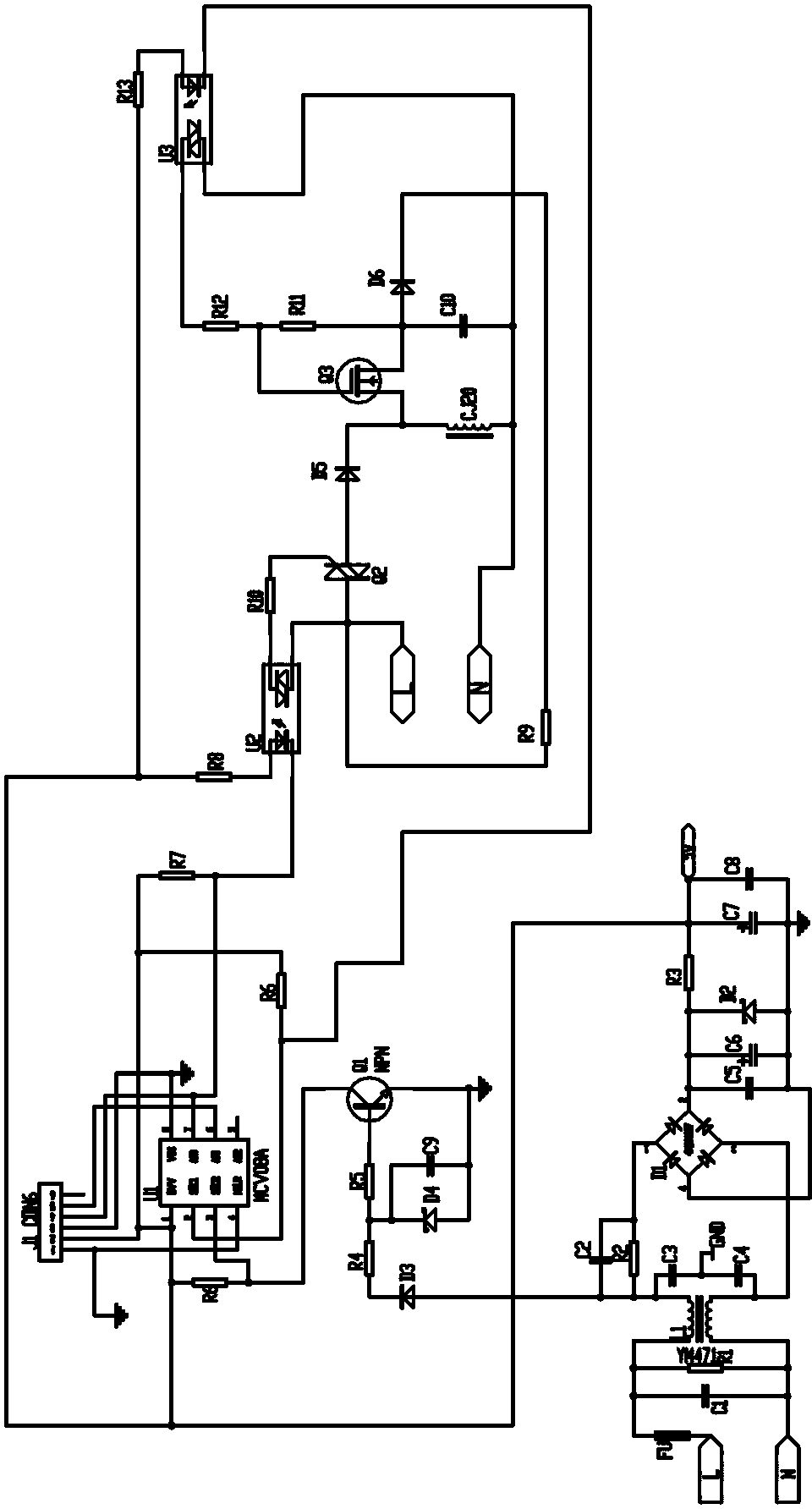

[0014] combine figure 2 It can be seen that the power input passes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com