Lithium-ion battery anode pole piece and lithium-ion battery comprising the anode pole piece

A lithium ion battery and pole piece technology, which is applied in the field of lithium ion battery anode pole piece and lithium ion battery including the anode pole piece, can solve the problem of the expansion and release of the anode membrane, the impact of the membrane on the safety and reliability of the battery, Reduce the content of active substances and other problems, achieve high gram capacity and energy density, good electron conduction, and solve the effect of swelling and film removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

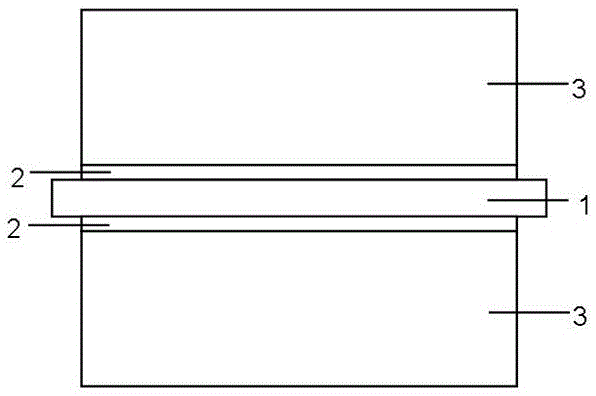

[0023] Embodiment 1: as figure 1 As shown, the anode sheet of a lithium ion battery provided in this embodiment includes a current collector 1 , a first coating 2 disposed on the surface of the current collector 1 , and a second coating 3 disposed on the surface of the first coating 2 . Wherein, the active substance in the second coating 3 is graphite, and the thickness of the second coating 3 is 20 μm; The ratio of the orthographic projection area is 1 (wherein, the orthographic projection area refers to the orthographic projection area of the plane where the length and width of the current collector 1 and the first coating 2 are located). And the first coating 2 is a composite material layer, and the composite material layer is composed of styrene-butadiene rubber and carbon powder, wherein the mass percentage of carbon powder to the total mass of the first coating is 90%.

[0024]During preparation, first disperse styrene-butadiene rubber into N-methylpyrrolidone to obta...

Embodiment 2

[0025] Embodiment 2: as figure 1 As shown, the anode sheet of a lithium ion battery provided in this embodiment includes a current collector 1 , a first coating 2 disposed on the surface of the current collector 1 , and a second coating 3 disposed on the surface of the first coating 2 . Wherein, the active material in the second coating 3 is a mixture of graphite and silicon (the mass ratio of the two is 7:3), and the thickness of the second coating 3 is 100 μm; the first coating 2 is a discontinuous coating layer, which includes several coating blocks distributed on the surface of the current collector 1, and the ratio of the sum of the orthographic projection areas of each coating block to the orthographic projection area of the current collector 1 is 0.5:1. The thickness of the first coating 2 is 1 μm, and the first coating 2 is a composite material layer, and the composite material layer is composed of polyvinylidene fluoride and carbon nanotubes, wherein the mass percen...

Embodiment 3

[0027] Embodiment 3: as figure 1 As shown, the anode sheet of a lithium ion battery provided in this embodiment includes a current collector 1 , a first coating 2 disposed on the surface of the current collector 1 , and a second coating 3 disposed on the surface of the first coating 2 . Wherein, the active material in the second coating 3 is a tin-carbon alloy, and the thickness of the second coating 3 is 50 μm; the first coating 2 is a discontinuous coating, which includes several smear blocks, and the ratio of the sum of the orthographic projection areas of each smear block to the orthographic projection area of the current collector 1 is 0.6:1. The thickness of the first coating 2 is 3 μm, and the first coating 2 is a composite material layer, and the composite material layer is composed of sodium carboxymethyl cellulose and vapor-phase grown carbon fibers, wherein the vapor-phase grown carbon fibers account for a mass of the total mass of the first coating The percentag...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com