Surface grinder motor stator assembling and disassembling system and using method thereof

A technology for motor stator and surface grinder, which is used in electromechanical devices, manufacturing of motor generators, electrical components, etc., can solve the problems of scrapped stator, damaged enameled wire of motor stator, and non-concentric bumped enameled wire.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

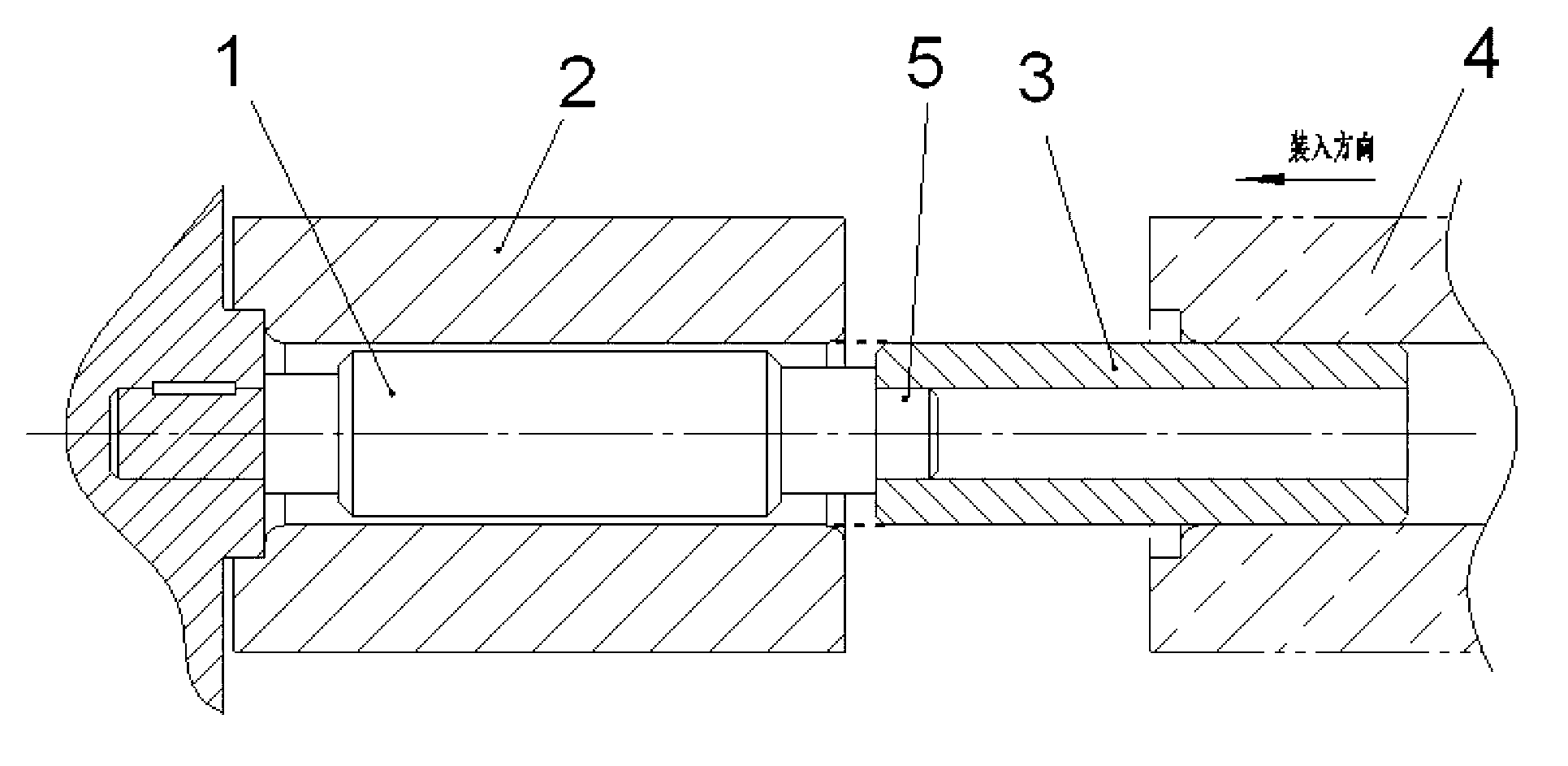

[0020] A motor stator disassembly system for a surface grinder, comprising a motor rotor 1, a motor stator 2, a stator guide sleeve 3 and a surface grinder 4, the motor stator 2 is arranged outside the motor rotor 1, and one end of the motor rotor 1 is provided with a positioning Step 5, the stator guide sleeve 3 is positioned on the outside of the motor rotor 1 at the positioning step 5, and the surface grinder 4 is connected to it at one end of the stator guide sleeve 3; the motor of the surface grinder 4 The center height is the same as the center height of the motor stator 2; the motor rotor 1 is set as a fixed non-detachable structure; the size of the stator introduction sleeve 3 matches the space size of the motor rotor 1; the stator introduction sleeve 3 The size is 300mm in diameter and 420mm in length; the stator guide sleeve 3 is made of steel; the size of the surface grinder 4 is 0.5m in width and 1.6m in length.

[0021] The use method of the surface grinder motor ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com