Method of monitoring appearance of surface of tyre

A technology of tires, images, applied in the field of operation of external or internal appearance, which can solve problems such as inability to determine convergence, inability to determine the elimination of local optima, the need for verbosity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

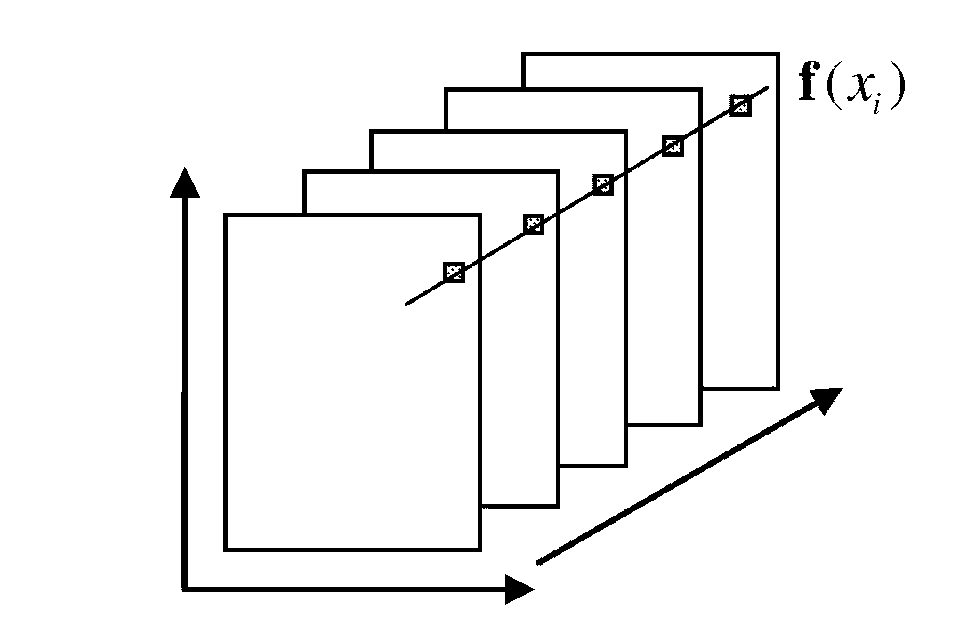

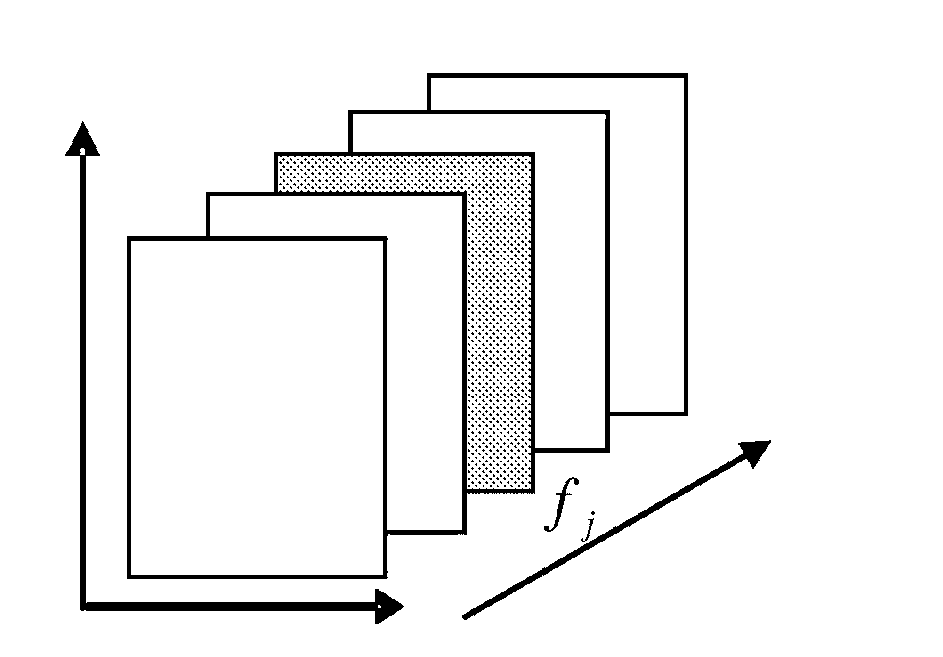

[0051] The detection method according to the invention comprises two distinct steps capable of revealing the presence or absence of anomalies and which can be considered as a training phase and a detection step, during which the factorial space, the transformation function and A classifier for detecting said anomalies on the surface of any tire to be classified.

[0052] The training phase begins by selecting at least one tire that includes a given anomaly visible on its surface. Anomalies of this type may be, for example, molding defects, oil stains, deviations of prestressing wires or creep of the rubber under the reinforcement layer, impurities, etc. Then, a two-dimensional black and white image of the anomaly is generated.

[0053] As will be shown later, this training phase can be made more robust by generating a series of two-dimensional images of said anomalies present on a number of different tire surfaces.

[0054] It is entirely possible to realize the invention by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com