Automatic film cutting device of film spreading machine

A technology of film laying machine and film device, which is applied in plant protection covers, metal processing, etc., can solve problems such as reduced operation quality, tooth removal, and excessive labor, and achieve stable and reliable performance, good film cutting effect, and high operation quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to describe the technical content, structural features, achieved goals and effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

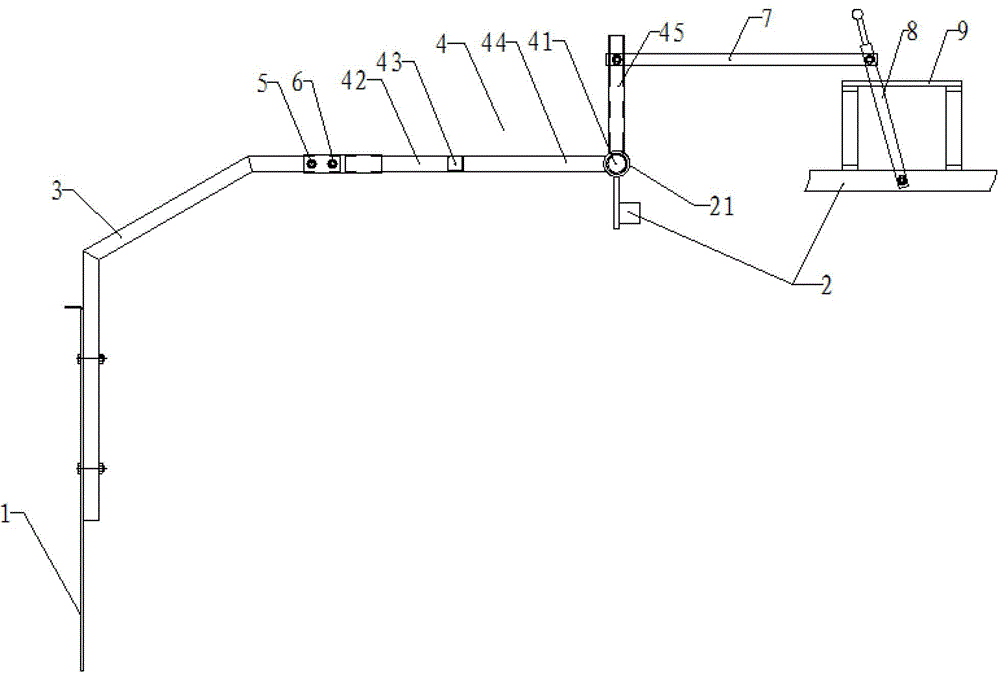

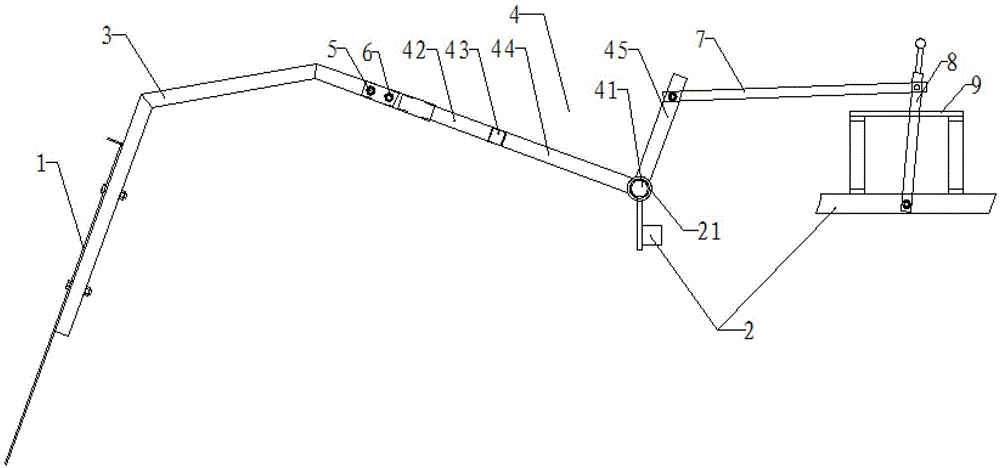

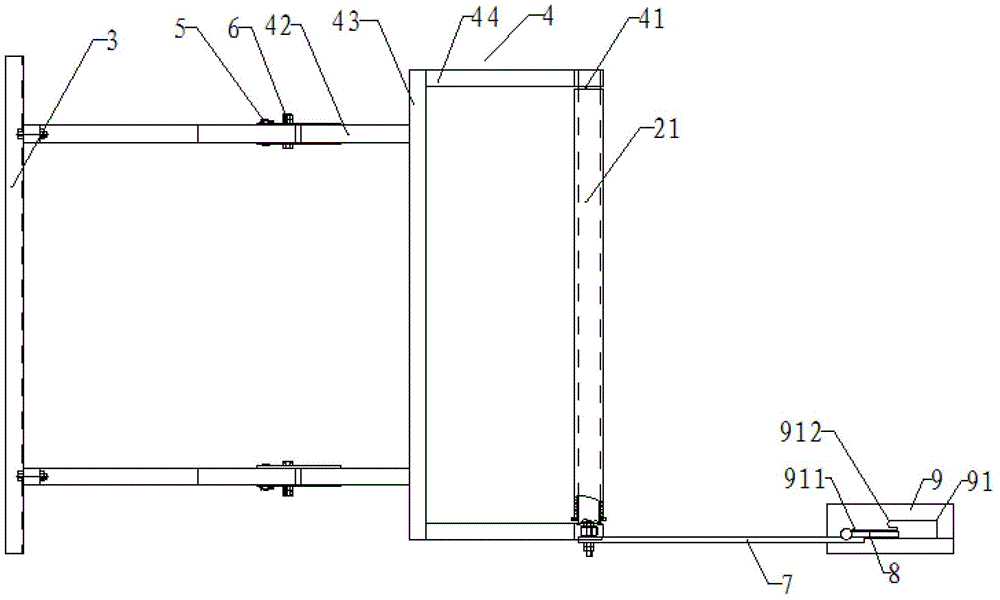

[0028] Please refer to the attached figure 1 to attach Figure 6 , as shown in the accompanying drawings, an automatic film cutting device of a film laying machine provided by the present invention includes:

[0029] cutter 1;

[0030] Cutter holder, the cutter 1 is fixed on the cutter holder;

[0031] The driving device, the cutter fixing frame is driven by the driving device to be swingably arranged on the frame 2 of the film laying machine, and the cutter fixing frame drives the cutter 1 to cut off the film covered on the furrow 10 while swinging.

[0032] When running, first start the driving device, the driving device drives the cutter fixed frame to swing on the frame 2 of the film laying machine, and further drives the movement o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com