UV adhesive curing and production device

A technology of production device and curing machine, which is applied to devices and coatings that apply liquid to the surface, can solve problems such as time-consuming and labor-intensive, and achieve the effect of avoiding the use of manpower, improving work efficiency, and saving labor and time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with the accompanying drawings.

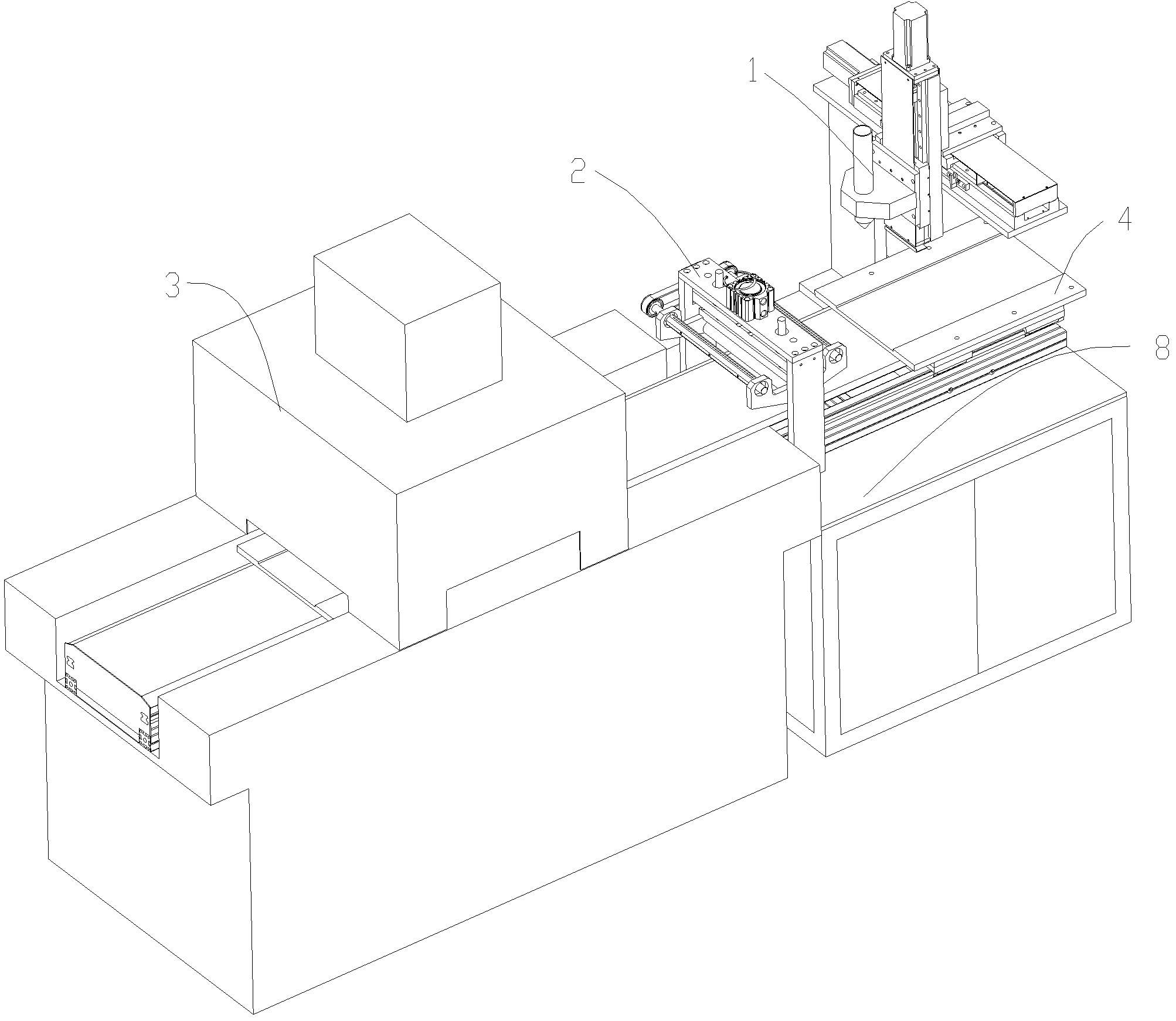

[0012] exist Figure 1-2 Among them, the UV glue curing production device includes a film, a template 4 that can be placed on the film, a glue dispenser 1, a glue rolling machine 2, a UV curing machine 3, and an automatic transmission device 5. The glue dispenser 1 can spot UV on the raw material film. Glue, and then the glue rolling machine 2 can roll the UV glue on the film flat, and finally the UV curing machine can cure the film after the UV glue is flattened at high temperature, and output the finished film. , glue rolling machine 2, and UV curing machine 3 transfer templates, so as to realize automatic transfer of film, save labor and time, and improve work efficiency.

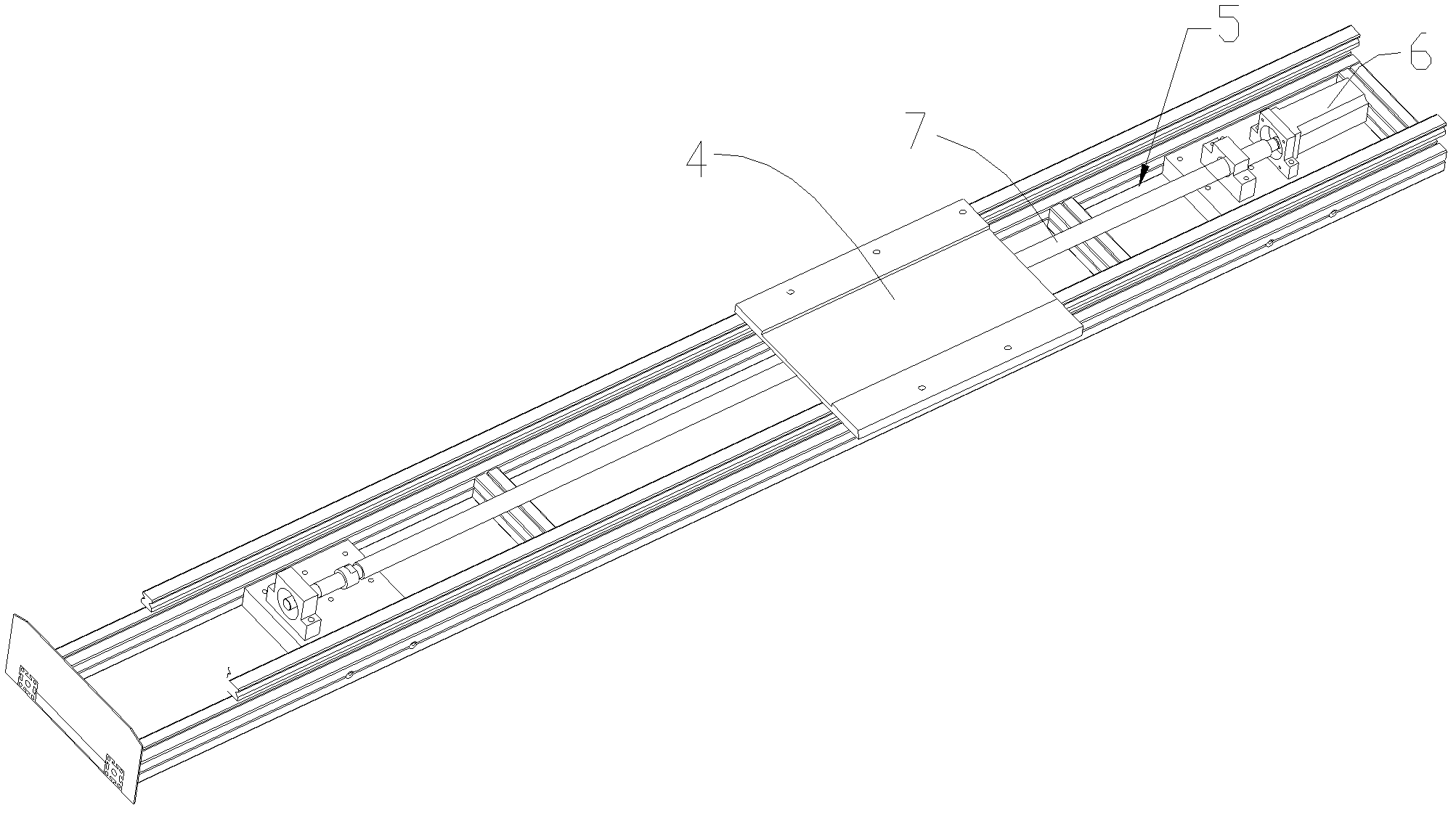

[0013] exist figure 1 and 2 Among them, the automatic transmission device 5 includes a motor 6, a rotating lead screw 7 whose coaxial center line is fixed on the output shaft of the mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com