Ramp starting method of electric drive tramcar for preventing sliding on ramp

A hill start, electric drive technology, applied in the direction of electric vehicles, control drive, electric energy management, etc., to achieve the effect of convenient on-board debugging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] A kind of electric drive mine car ramp start method that prevents the slope of the embodiment of the present invention, comprises the following steps:

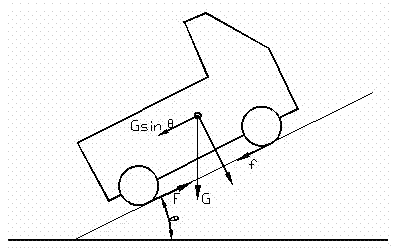

[0024] Step 1, such as figure 1 As shown in , the estimated gravity component Gsinθ when the vehicle is driving on a slope is calculated by the following formula 1,

[0025] F-(Gsinθ+f)=ma (1),

[0026] Where F is the motor torque, G is the gravity of the vehicle, θ is the gradient of the ramp, f is the resistance, m is the mass, and a is the acceleration;

[0027] The motor torque F is the force obtained by motor control, which is a known force and can be obtained through existing vehicle equipment; the preferred acceleration a is measured by the speed sensor; the resistance f is about 2% of the vehicle weight; it can be calculated from the known quantities above Get the gravity component Gsinθ of the vehicle along the ramp.

[0028] In the embodiment of the present invention, the corresponding relationship betwee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com