Explosion-proof source bottle for diffusion technology

A diffusion process and source bottle technology, applied in the directions of diffusion/doping, crystal growth, post-processing, etc., can solve the problems of blockage of the gas outlet pipeline, explosion of the source bottle, high danger, etc., and achieve the effect of avoiding danger.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

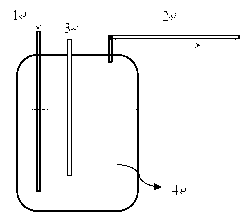

Image

Examples

Embodiment Construction

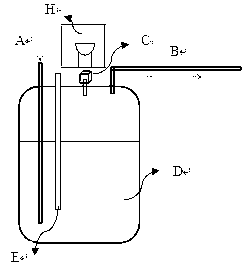

[0010] Below in conjunction with accompanying drawing, the technical scheme of the patent of the present invention is described in further detail.

[0011] Such as figure 2 As shown in the figure, an explosion-proof source bottle for the diffusion process is composed of an air inlet pipe, an air outlet pipe, a temperature measuring pipe, a metal block, and a buzzer. When the inlet pipe A is fed with nitrogen gas, the liquid phosphorus oxychloride D enters the furnace cavity from the outlet pipe B along with the small nitrogen carrying source, and the process of diffusion reaction begins. Install a metal block on the top of the explosion-proof source bottle. When the air pressure in the bottle is too high, the metal block is lifted to release the pressure, the circuit is turned on, and the buzzer alarms; when the air pressure is restored, the metal block falls, and the buzzer stops alarming. .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com