Safety pressure-relieving valve for explosion-proof compressed-air storing tank

A technology of compressed air and safety valves, applied in the field of safety pressure relief valves, which can solve the problems of explosion threats in the surrounding environment, no alarm function, and leakage of combustible gas, etc., and achieve the effects of simple structure, material cost saving, and overall quality reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with accompanying drawing.

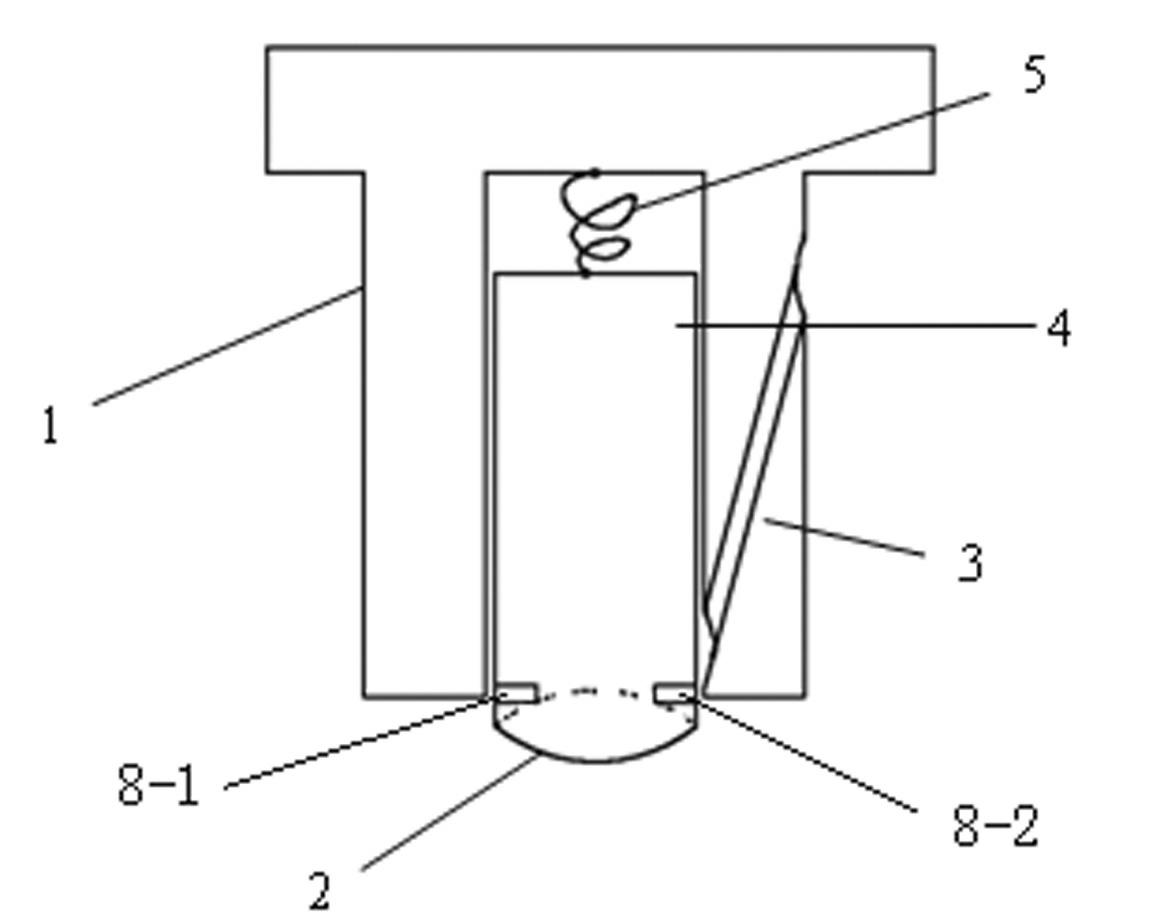

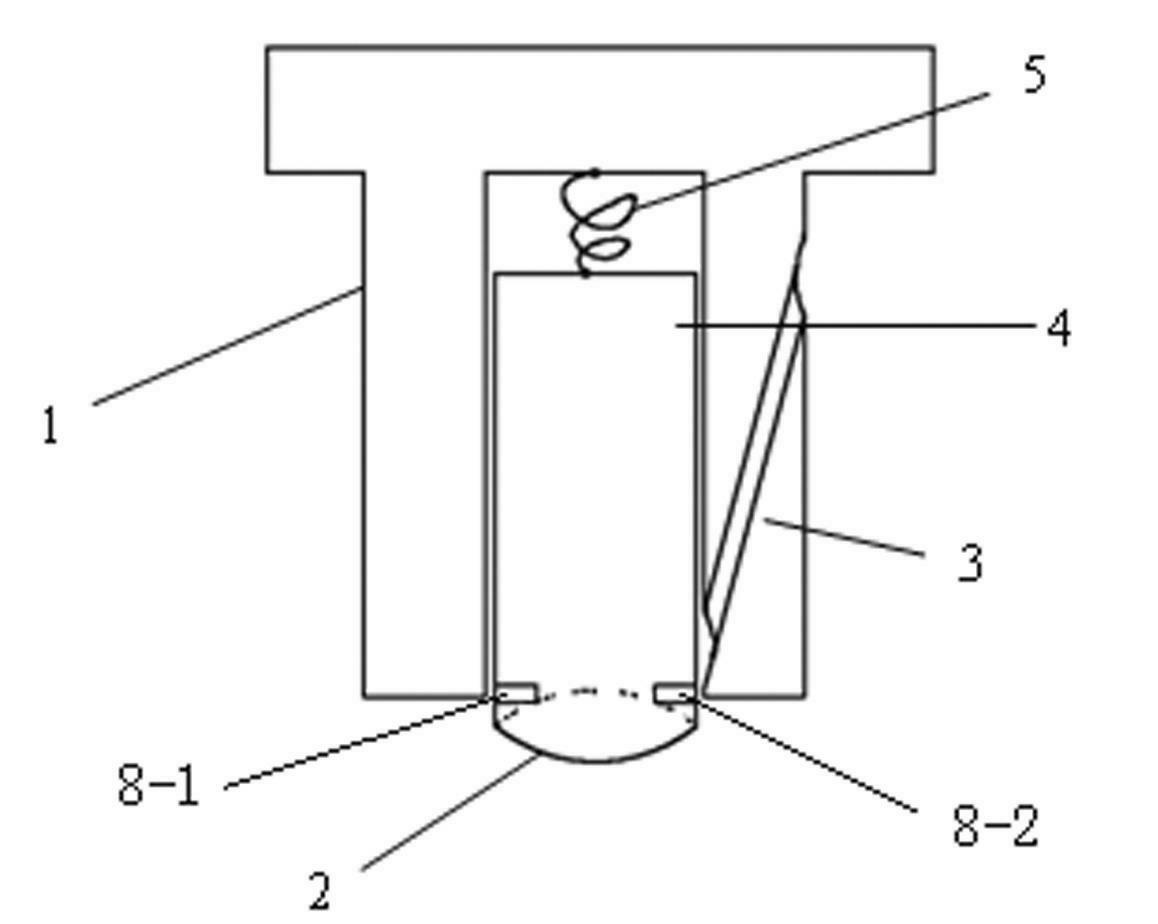

[0016] refer to figure 1 , the present embodiment includes a safety valve body 1, the safety valve body 1 is provided with a movable tappet 4, the movable tappet 4 is connected with the safety valve body 1 through an elastic support member 5, the elastic support member 5 is a spring, and the movable tappet 4 is connected to the safety valve body 1. The lower end of the column 4 is provided with an elastic metal diaphragm 2, two metal contact pieces I 8-1 and metal contact piece II 8-2 are arranged above the elastic metal diaphragm 2, and a pressure relief groove 3 is provided on the safety valve body 1. The contact piece I 8-1 and the metal contact piece II 8-2 are connected in the early warning circuit.

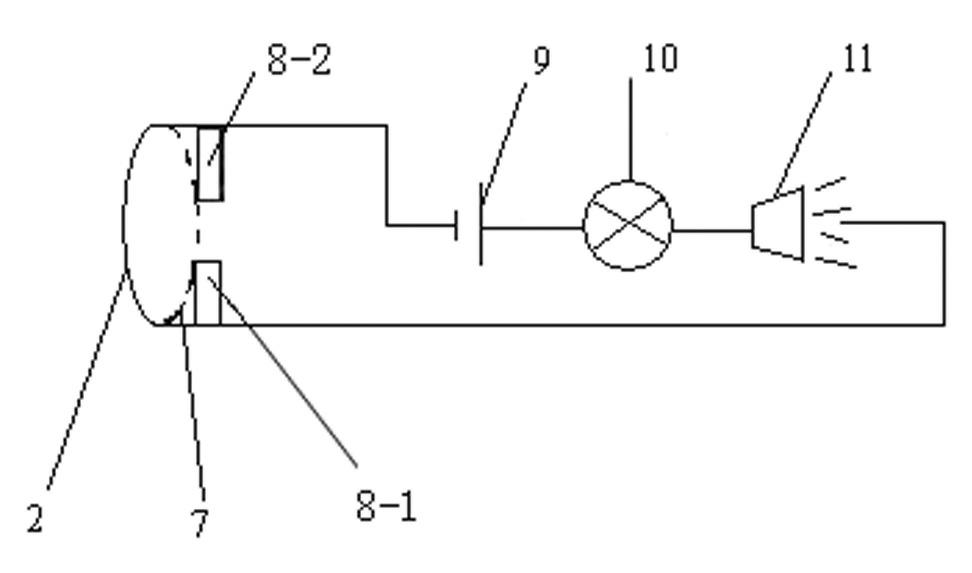

[0017] refer to figure 2 , The early warning circuit includes a power supply 9, a warning light 10, and a buzzer 11, and the power supply 9, the warning light 10, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com