Manual hole pile digging method employing top-fixing water drilling method

A technology of manual hole-digging piles and water drilling method, which is applied in the direction of sheet pile walls, foundation structure engineering, construction, etc., can solve the problems of low construction efficiency, achieve the effects of reducing fixing time, improving foundation excavation efficiency, and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The implementation of the present invention will be described in detail below in conjunction with the accompanying drawings, but they do not constitute a limitation to the present invention, and are only examples. At the same time, the advantages of the present invention will become clearer and easier to understand.

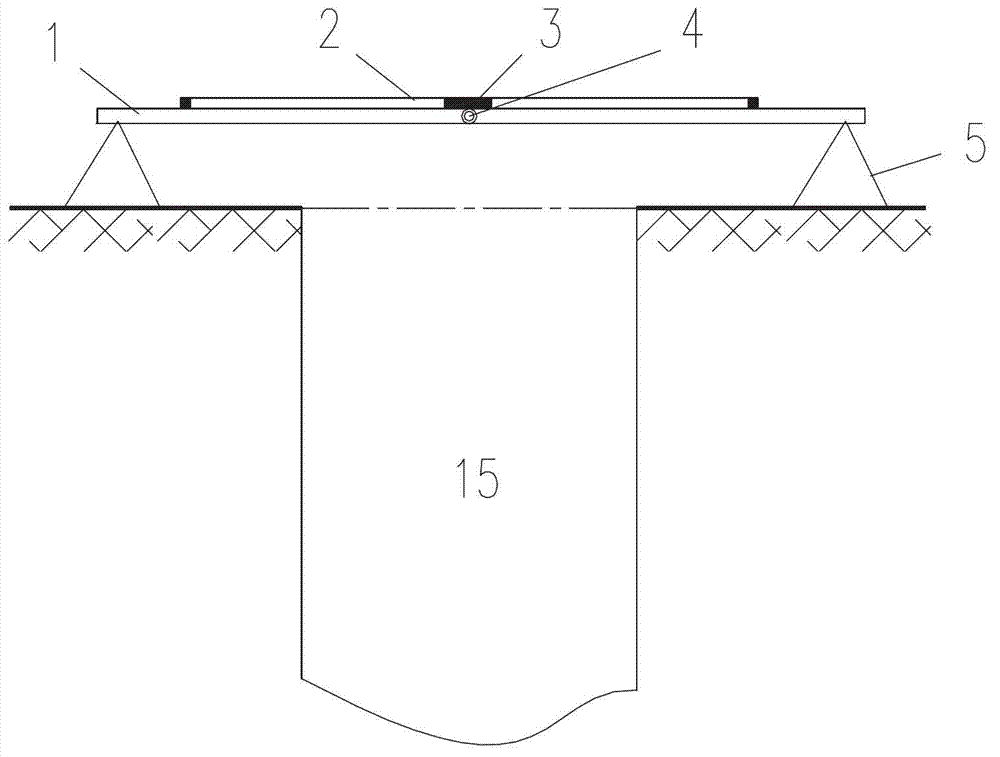

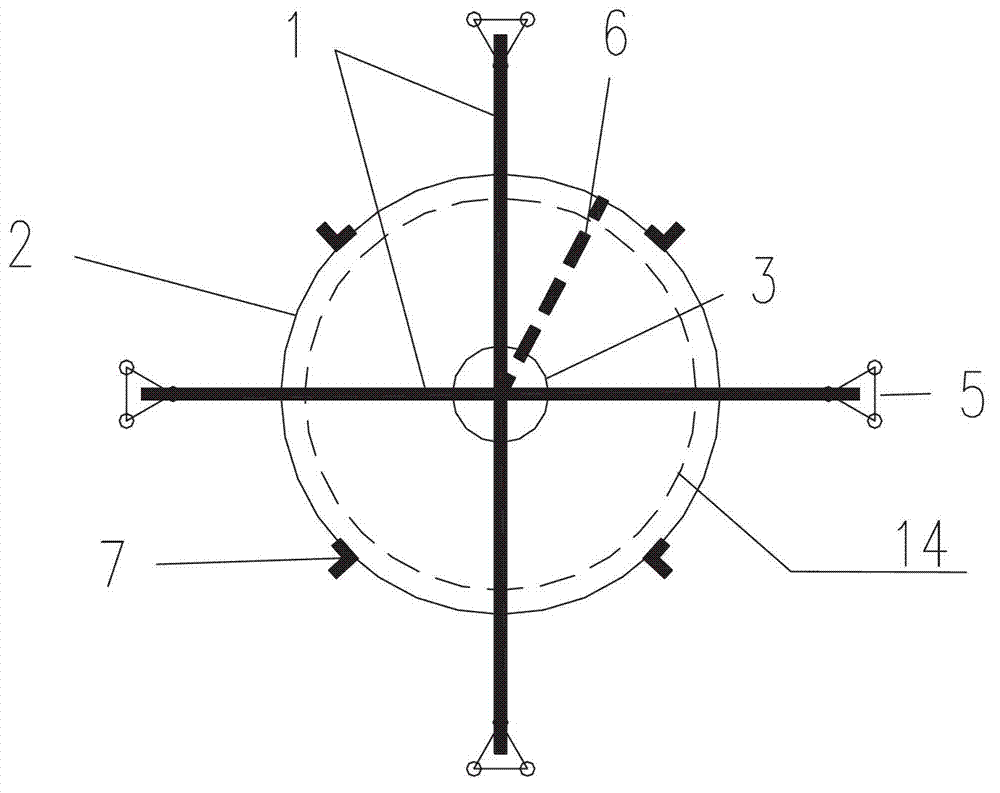

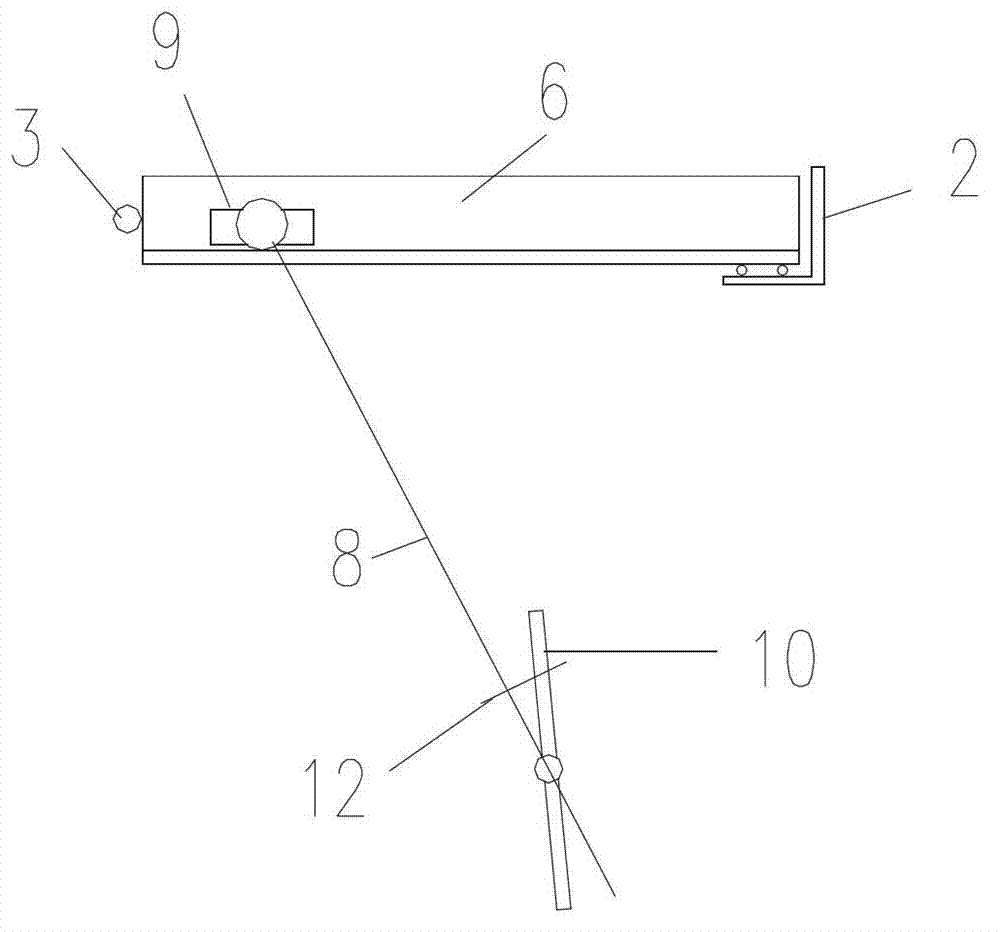

[0022] In this construction method, the top fixed rhinestone support is divided into external support and internal support. When the hole depth is less than 2 meters, use the external support method to fix the water drilling rig. When the hole depth is greater than 2 meters, the rigidity of the support system is required to increase, so it is more efficient to use the internal support method to fix the drilling rig.

[0023] Referring to the accompanying drawings as can be seen: the top of the present invention fixed water drilling method manual hole-digging pile method is characterized in that it comprises the following steps:

[0024] ① When the hole d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com