Anti-explosion closing part of wall bushing and plugging method of wall bushing

A technology for through-wall sleeves and pipeline holes, which is applied in the direction of pipes/pipe joints/fittings, pipes, mechanical equipment, etc., which can solve the problems of difficult construction, poor sealing of the upper half of the pipe hole, and complicated construction, etc., to solve the problem of construction The order is chaotic, the airtight function is effective, and there is no effect of construction pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

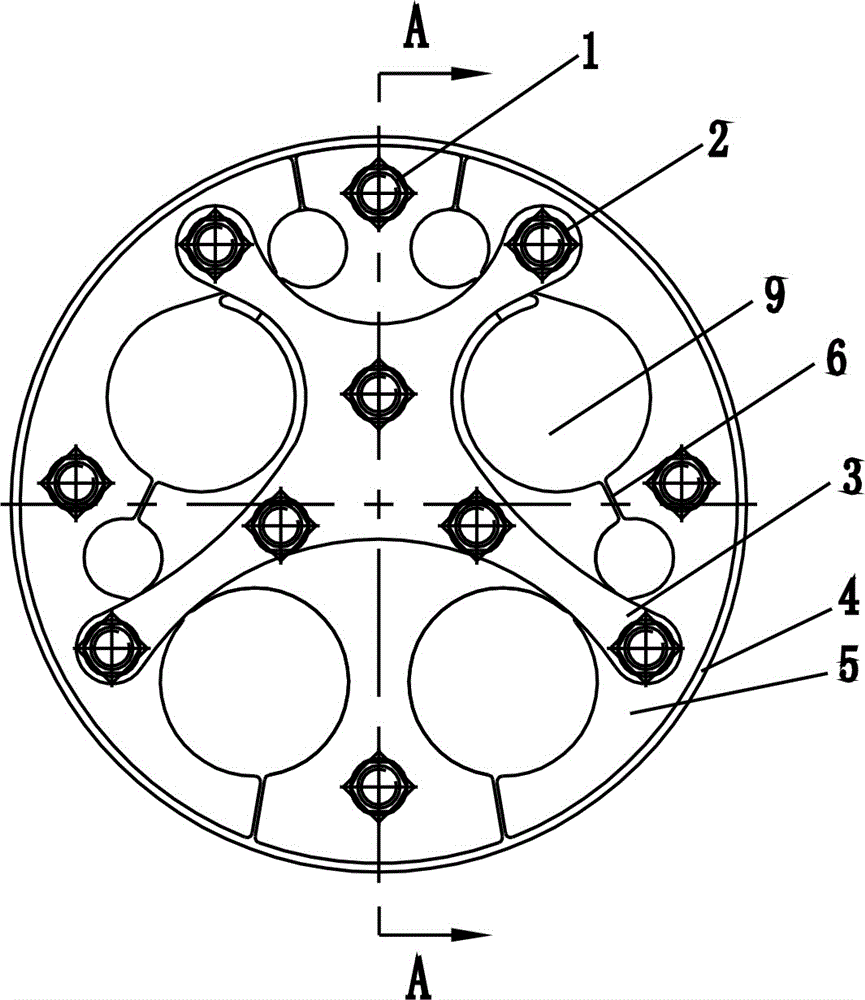

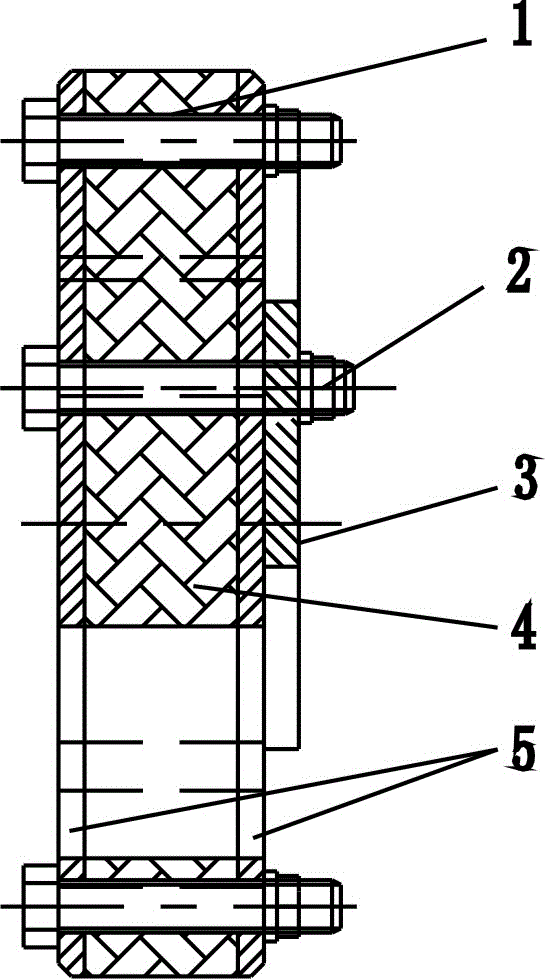

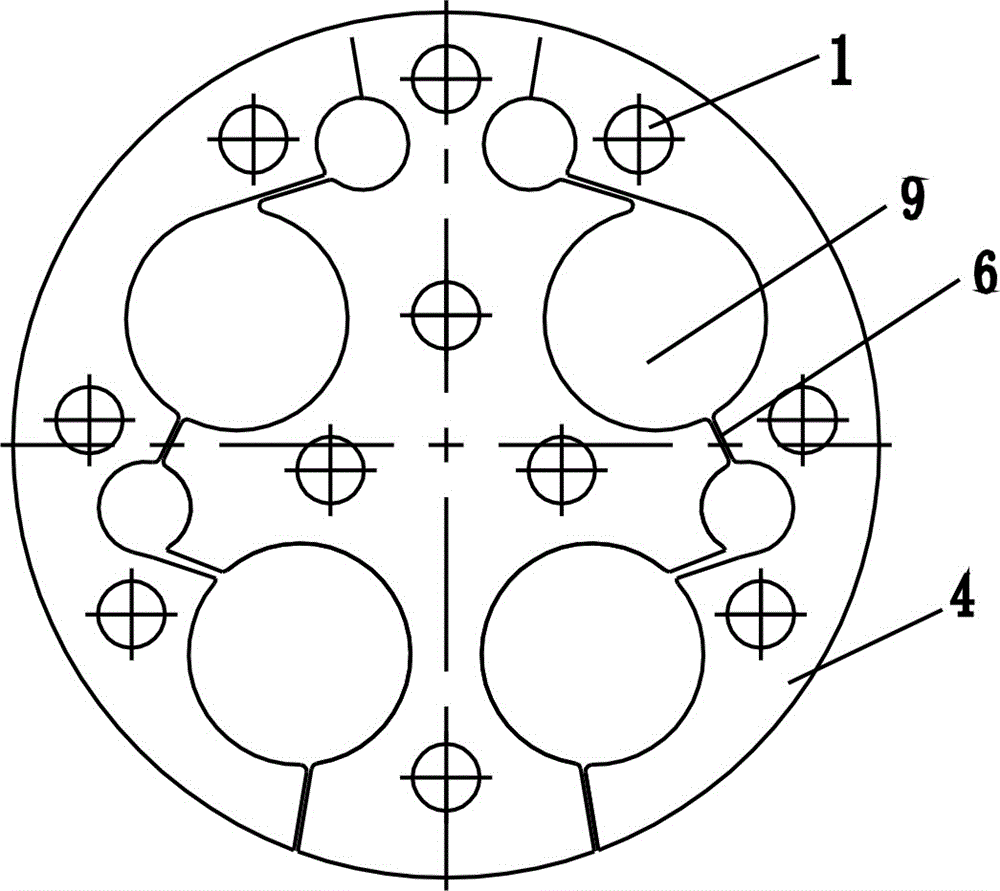

[0019] see Figure 1-5 , this embodiment includes an elastic and flexible extruded block 4, and splints 5 are arranged on both sides of the extruded block 4, and the splint 5 may be a steel plate with better rigidity. At least one pipeline hole 9 and at least one connection hole 1 are evenly distributed at the corresponding positions of the extrusion block 4 and the two splints 5, and the fastening parts for fastening and connecting the two splints and the extrusion block are arranged in the connection hole 1. Can be mating snaps, hinges or extruded bolts, nuts. This implementation case takes the bolt as an example, the fastening part connecting hole 1 is provided with a special bolt 2 with a special bolt tail, and a screw rod can also be used.

[0020] The extrusion block 4 and the two splints 5 are provided with cutting grooves 6 that divide the pipeline holes 9, and one of the splints or the outside of the two splints is provided with a cut groove 6 that spans the pipeline...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap