Multipurpose coating and plating layer laser measuring arm

A measuring arm and multi-purpose technology, which is applied in the direction of measuring devices, optical devices, instruments, etc., can solve the problems of low measurement accuracy, large device volume, and high machining accuracy requirements, and achieve good economy, simple operation, and high precision. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in detail below in conjunction with specific embodiments.

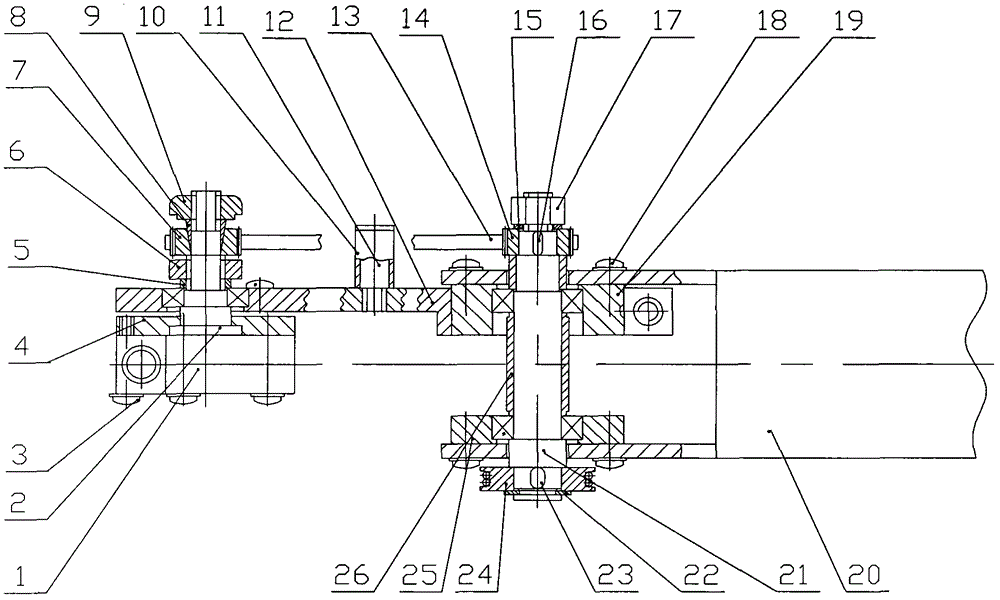

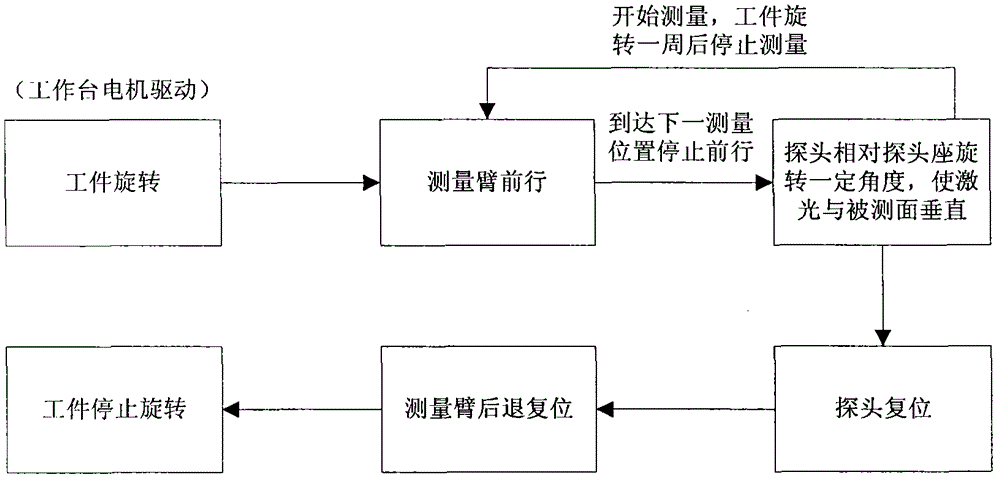

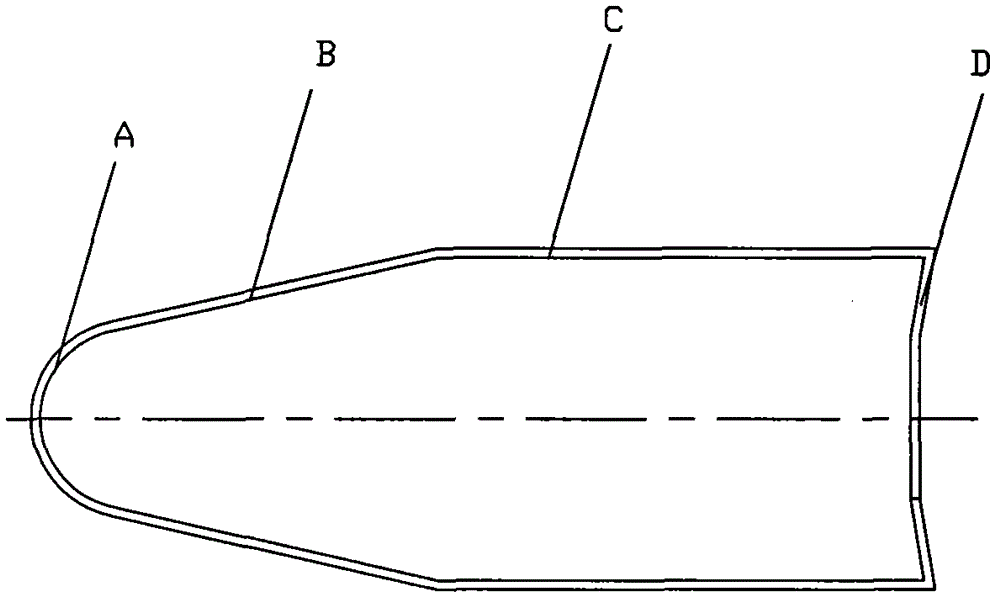

[0020] The multi-purpose coating laser measuring arm (for convenience, the multi-purpose coating laser measuring arm is referred to as the measuring arm hereinafter) includes a measuring system, a clutch device, a transmission system and a rotating device, a horizontal moving device and a vertical moving device (Fig. not shown in ), the measurement system uses a laser probe to measure the coating thickness of the measured surface, the clutch device is used to realize the separation and engagement of the measurement system and the transmission system, and the transmission system is used to drive the laser probe of the measurement system to achieve a certain angle of rotation The rotating device is used to switch between the general working mode and the special working mode of the measuring system, and the horizontal moving device and the vertical moving device are used to d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com