Integrated monitoring system for wave soldering

A comprehensive monitoring system and wave soldering technology, applied in the direction of comprehensive factory control, comprehensive factory control, electrical program control, etc., can solve problems such as flux changes, equipment management personnel unable to understand information in time, equipment management personnel unable to understand in time, etc. To achieve the effect of improving effective management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Embodiments of the present invention are described in detail below in conjunction with accompanying drawings:

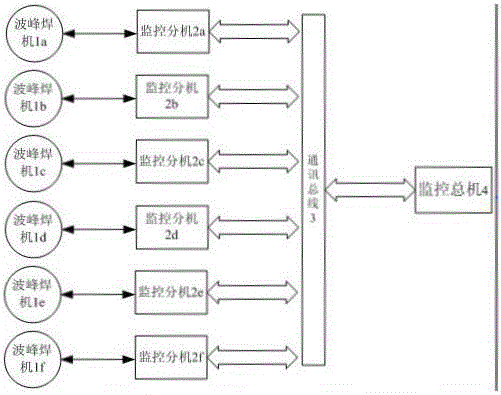

[0032] like figure 1 As shown, the wave soldering integrated monitoring system of the present invention includes at least one wave soldering machine, at least one monitoring extension, a monitoring switchboard 4 and a communication bus 3, and the monitoring extension is connected to the wave soldering machine correspondingly. The monitoring extension is connected to the communication bus 3 through a communication line, and the communication bus 3 is connected to the monitoring switchboard 4 through a communication line; wherein, the monitoring extension obtains the parameter information of the wave soldering machine connected to it in real time, The parameter information of other wave soldering machines acquired by other monitoring extensions is obtained in real time through the communication bus, and at the same time, the communication bus 3 also sends all pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com