Laser diode control circuit, and laser diode control device provided with the circuit

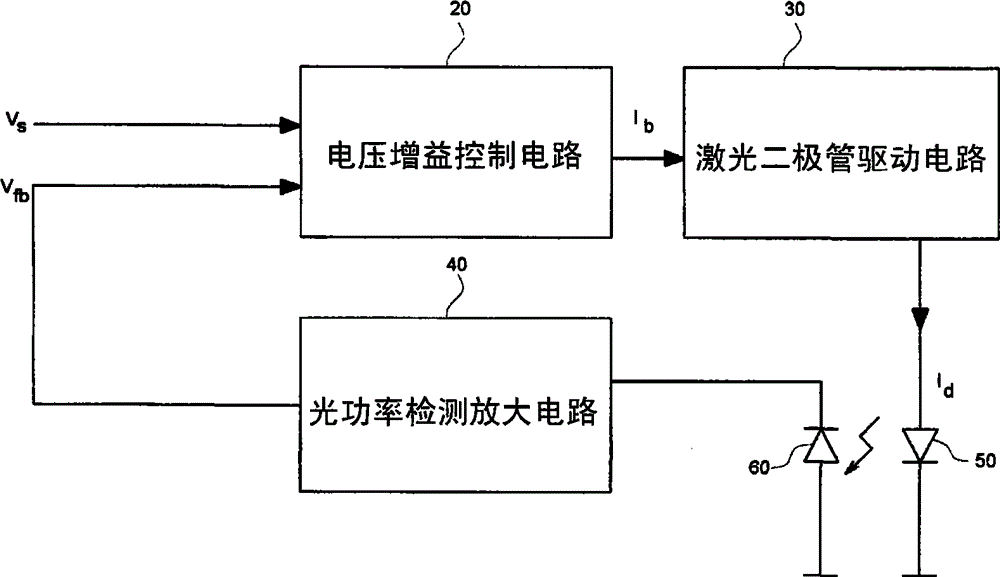

A technology of laser diodes and control circuits, which is applied in beam sources, optical recording heads, optical recording/reproduction/erasing methods, etc., and can solve problems such as manufacturing inconvenience, gain change, and burning read-write heads, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

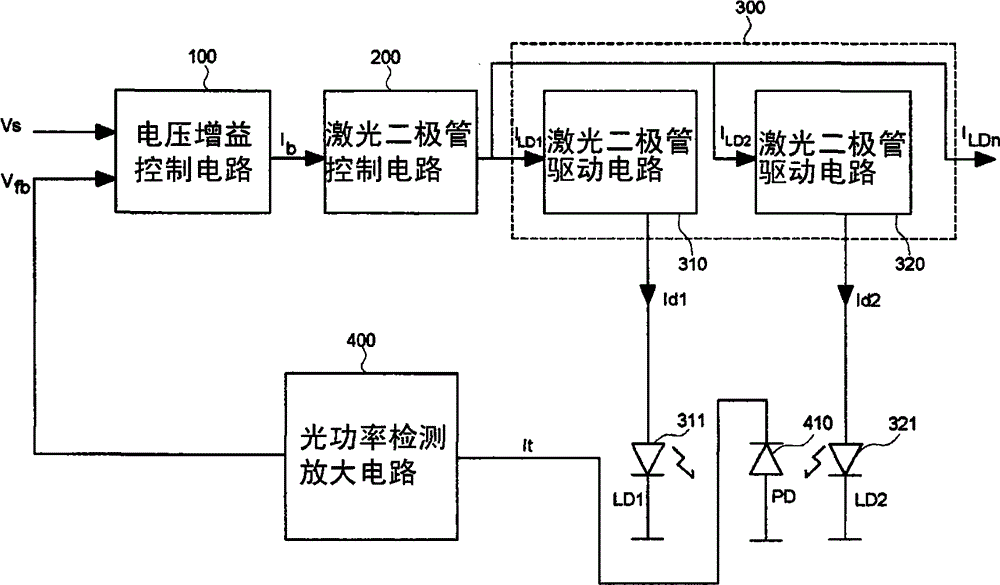

[0018] First, please refer to figure 2 , is a functional block diagram of the laser diode control device of the present invention. Such as figure 2 As shown, the laser diode control device includes a voltage gain control circuit 100, which can output a voltage and convert it into a current I b output to a laser diode control circuit 200, and then the output terminal of the laser diode control circuit 200 and a plurality of different laser diode drive circuits (for example: laser diode drive circuit 310 and laser diode drive circuit 320 are used to drive different laser diode drive circuits respectively. The driving circuit 300 composed of laser diodes 311 / 321) is connected, and then through the selection signal in the laser diode control circuit 200 (not shown in figure 2 in; will be image 3 shown and described in ) to select a laser diode drive circuit in the drive circuit 300 (for example: select the laser diode drive circuit 310) and make it output a current I LD to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com