Temporary roof cover of nuclear island safety shell

A containment and temporary technology, which is applied in the field of temporary roof, can solve the problems of failure to meet the construction progress and safety requirements of the third-generation nuclear power project, labor and time-consuming installation and disassembly, and equipment cannot be protected, etc., to achieve simplified transmission and layout, Reduced man-hours, flexible opening and closing operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to make the present invention more comprehensible, preferred embodiments are described in detail below with accompanying drawings.

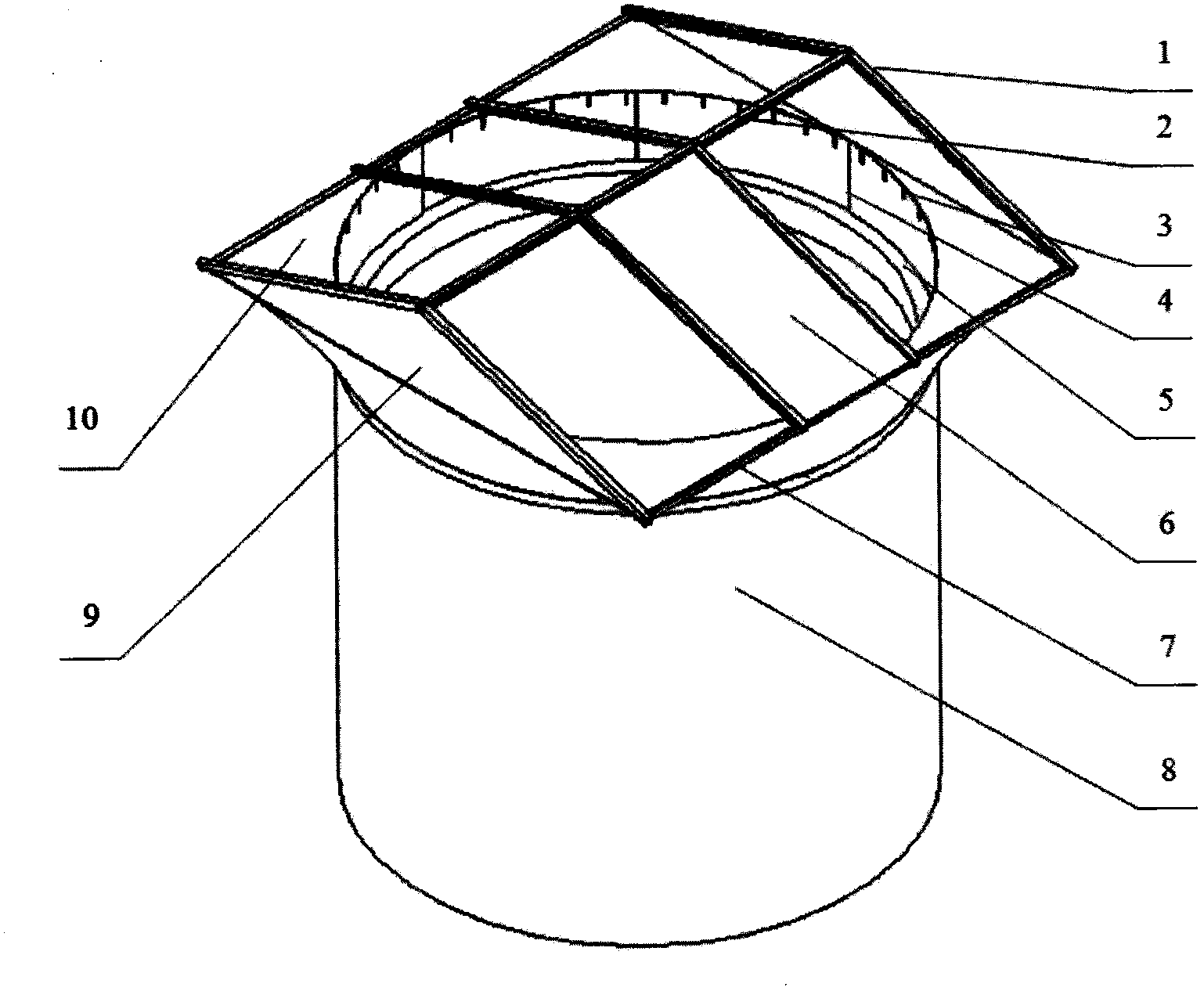

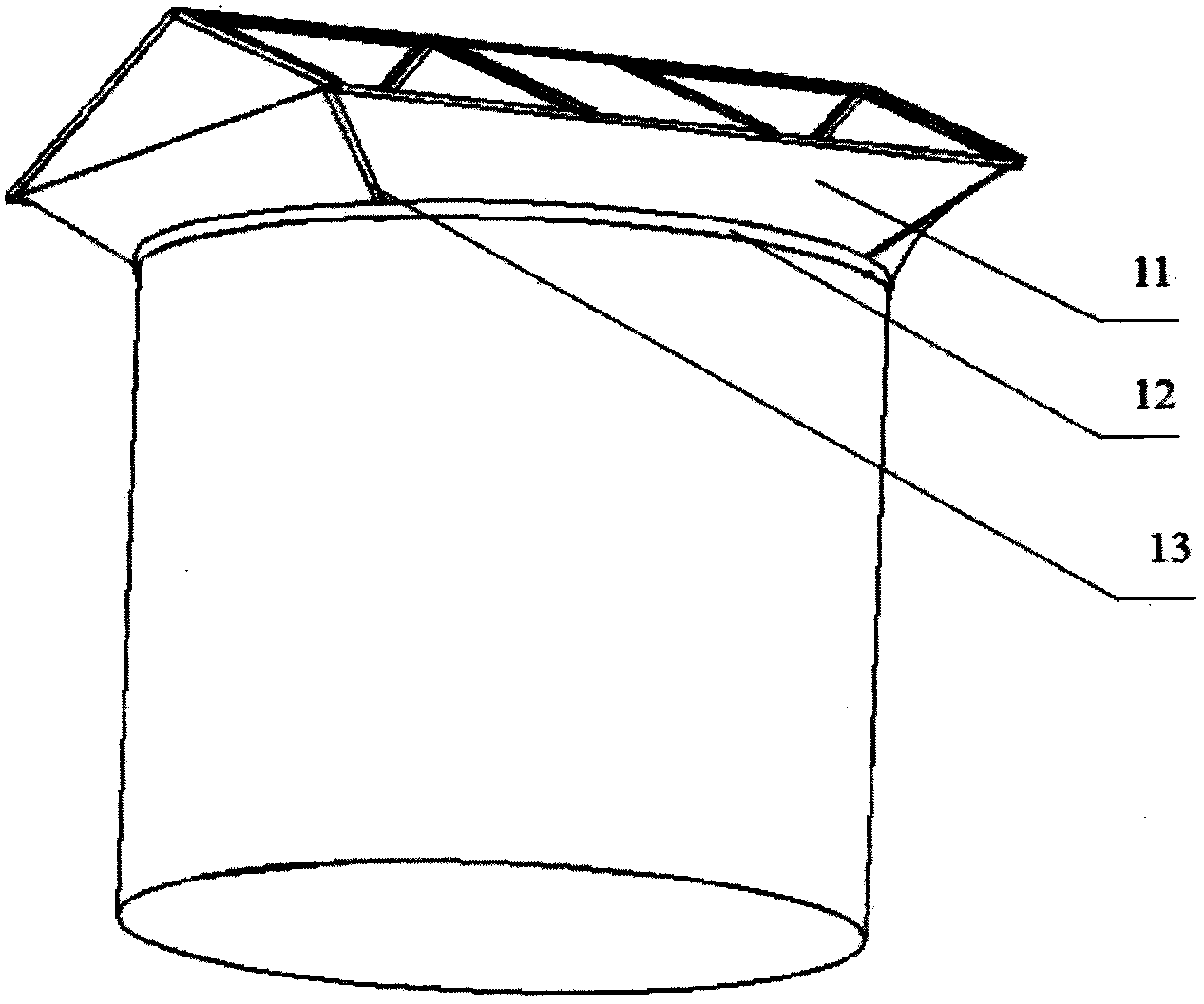

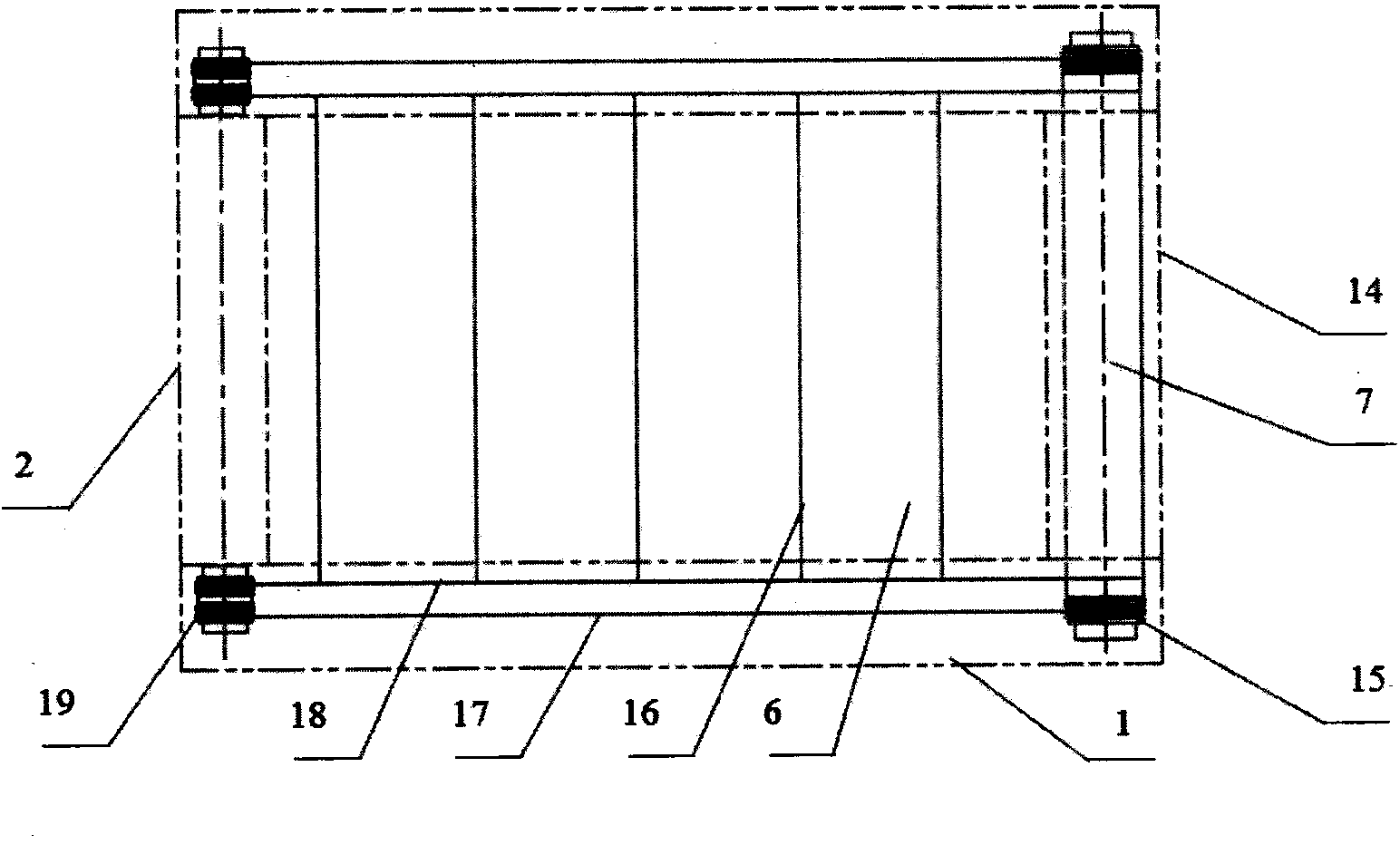

[0019] Such as figure 1 and figure 2 As shown, the temporary roof of the nuclear island containment vessel disclosed in this embodiment includes a roof-shaped three-dimensional frame on the top, and the three-dimensional frame is the top cover of the temporary roof of the entire nuclear island containment vessel. The section of the space frame is triangular. The space frame comprises beams 2 at the top. The crossbeam 2 can be designed as three independent sections, and a certain section can be temporarily disassembled when hoisting super-large and super-long pieces. The first waterproof material 9 is respectively fixedly installed on the left and right sides of the beam 2 in a direction perpendicular to the cross-section of the three-dimensional frame. Four oblique and detachable slanting beams 1 are connected to the front an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com