A steam generator heat transfer tube defect inspection device and its application method

A technology of steam generator and defect inspection, applied in nuclear power generation, nuclear reactor monitoring, reactor and other directions, can solve problems such as missed inspection, and achieve the effect of preventing water leakage and good sliding sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

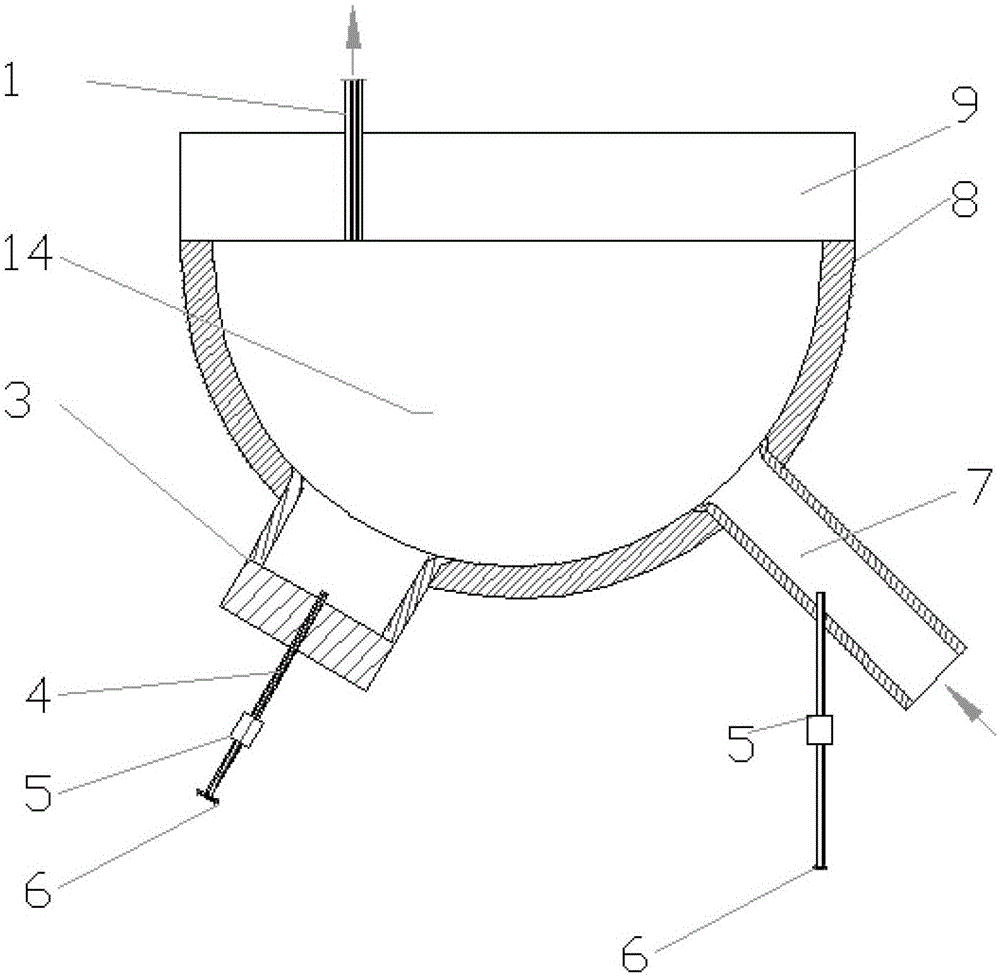

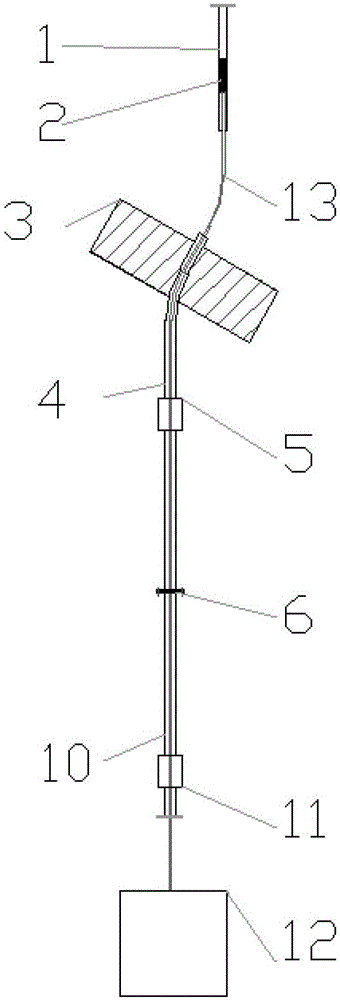

[0026] The present invention provides a defect inspection device for a heat transfer tube of a steam generator and a method for using the same. The present invention will be further described below with reference to the accompanying drawings and specific embodiments.

[0027] A steam generator heat transfer tube defect inspection device, characterized in that: the device consists of a probe mechanism 2, a catheter 13, a first catheter sheath 4, a second catheter sheath 10, a valve 5, a sliding seal assembly 11, and a connecting flange 6. and the pusher 12;

[0028] The front end of the catheter 13 is connected with the probe mechanism 2, and the rear end is connected with the pusher 12; a first catheter sheath 4 and a second catheter sheath 10 are arranged outside the catheter 13, and the two are connected through the connecting flange 6; the first catheter sheath penetrates the human body The hole cover plate 3 or the lower head nozzle 7, the first catheter sheath 4 is welded...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com