Method for enabling external rotor motor to controlly transform output parameters and external rotor motor

A technology of external rotor motor and output parameters, which is applied in the fields of motors, power management, electric vehicles, etc., can solve the problems of inapplicable vehicle use, small variation range, and inability to popularize special external rotor motors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

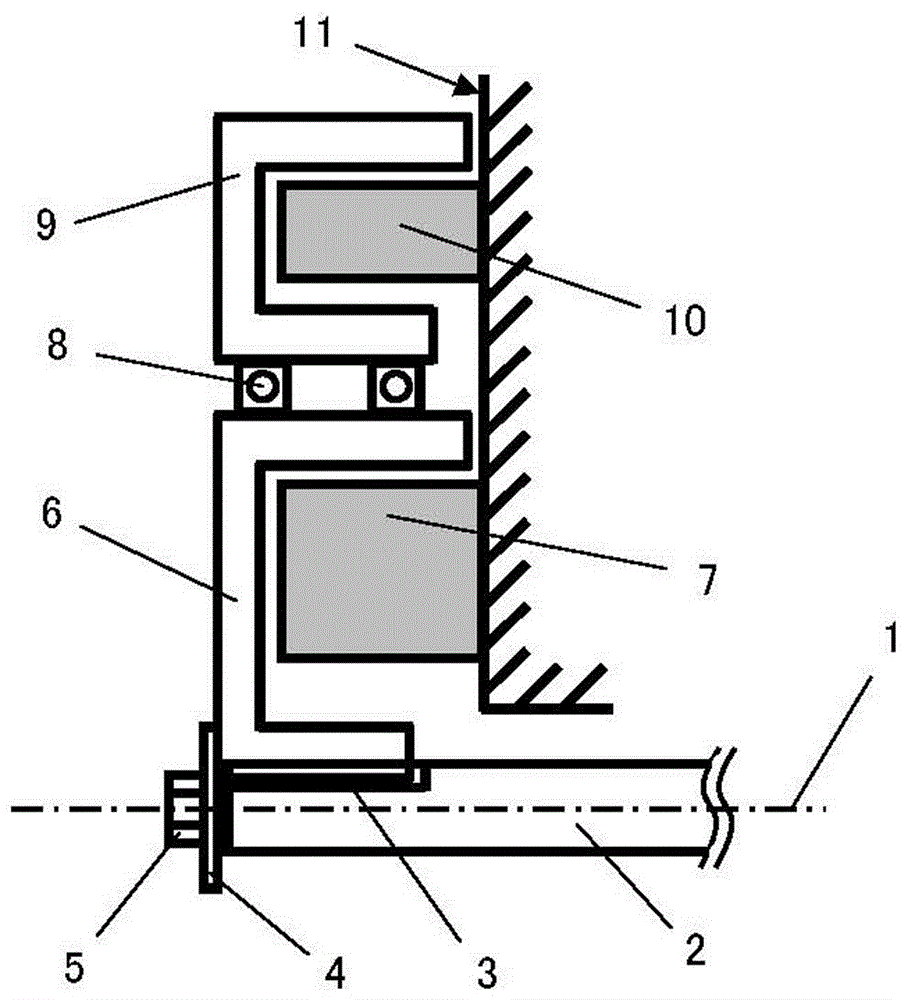

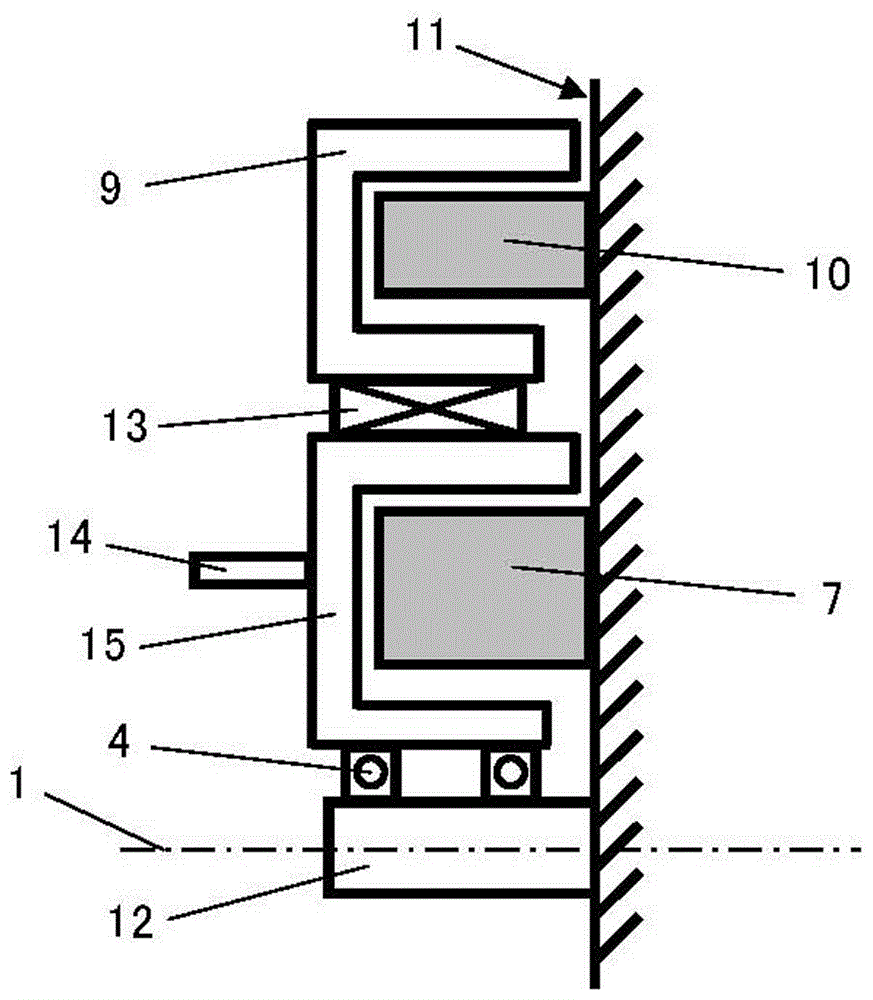

[0073] Further details will be given below in conjunction with various embodiments shown in the accompanying drawings.

[0074] The present invention proposes an external rotor motor capable of controlled transformation of output parameters, such as figure 1 and figure 2 As shown, it includes a first outer rotor motor unit and a second outer rotor motor unit. The first outer rotor motor unit includes a first stator 7 fixedly mounted on a fixture 11, and a first rotor 6, 15 rotating on the outer periphery of the first stator. The second outer rotor motor unit includes a second stator 10 fixedly installed on the fixture, and a second rotor 9 rotating on the outer periphery of the second stator 10 . The second rotor 9 connects or disconnects the first rotor 6 , 15 in a controlled manner. When the first rotor 6 , 15 is connected to the second rotor 9 , the second rotor 9 rotates with the first rotor 6 , 15 . When the first rotor 6 , 15 is disconnected from the second rotor 9 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com