Magnetic suspension bearing, motor, compressor and air conditioner

A magnetic suspension bearing and bearing stator technology, which is applied in the fields of compressors, air conditioners, motors, and magnetic suspension bearings, can solve problems such as high cost, connection quality problems, and complex wiring structures.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

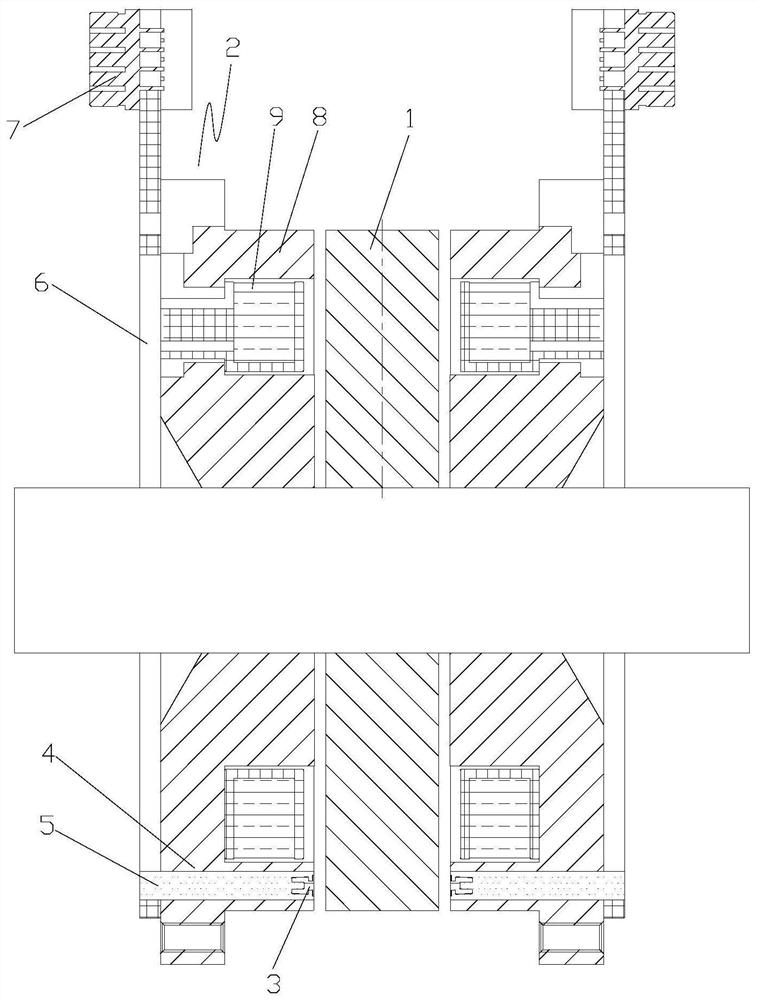

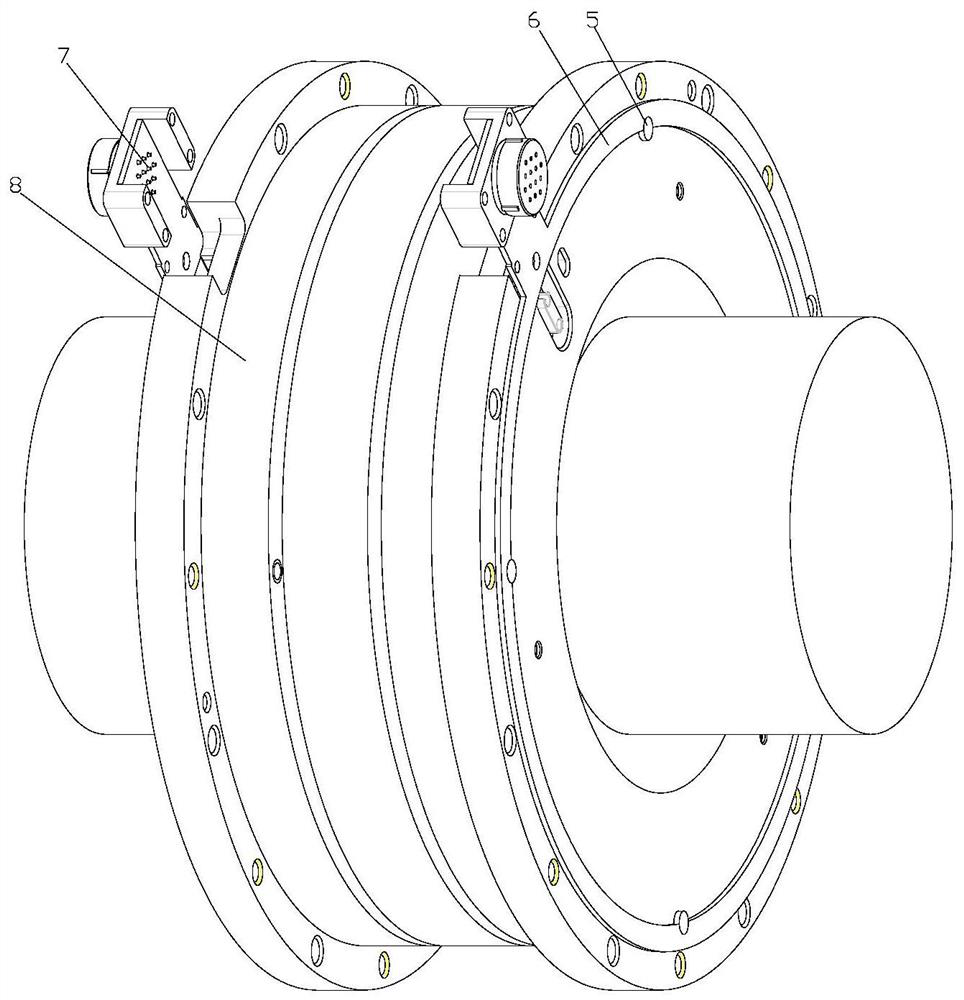

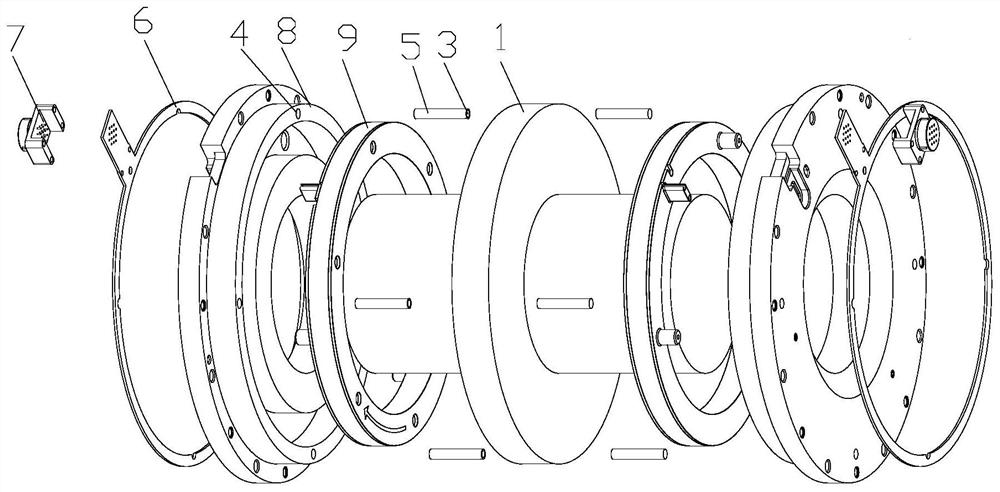

[0028] see in conjunction Figure 1 to Figure 5 As shown, according to the embodiment of the present application, the magnetic suspension bearing includes a thrust bearing 1, an axial bearing stator 2 and an axial displacement detection device 3, and the axial displacement detection device 3 is used to detect the axial position of the thrust bearing 1. The axial ends of the thrust bearing 1 are respectively provided with axial bearing stators 2, and at least one of the axial bearing stators 2 is provided with an axial displacement detection device 3, and the axial displacement detection device 3 and the axial bearing stator where it is located 2 is an integrated structure.

[0029] The magnetic suspension bearing forms an integrated structure between the axial displacement detection device 3 for measuring the axial position of the thrust bearing 1 and the axial bearing stator 2, and does not require a separate axial arrangement of the axial displacement detection device 3, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com