Control valve having a curved spring hinge serving as a non-return valve

A technology for controlling valves and elastic bands, applied in the field of proportional valves, which can solve the problems of backflow of operating medium and damage to other components, and achieve the effect of high flow rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

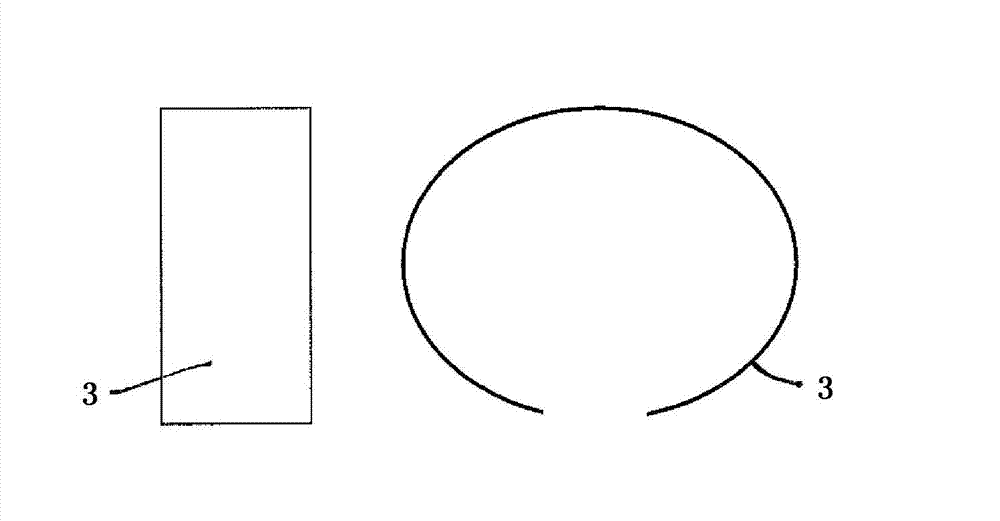

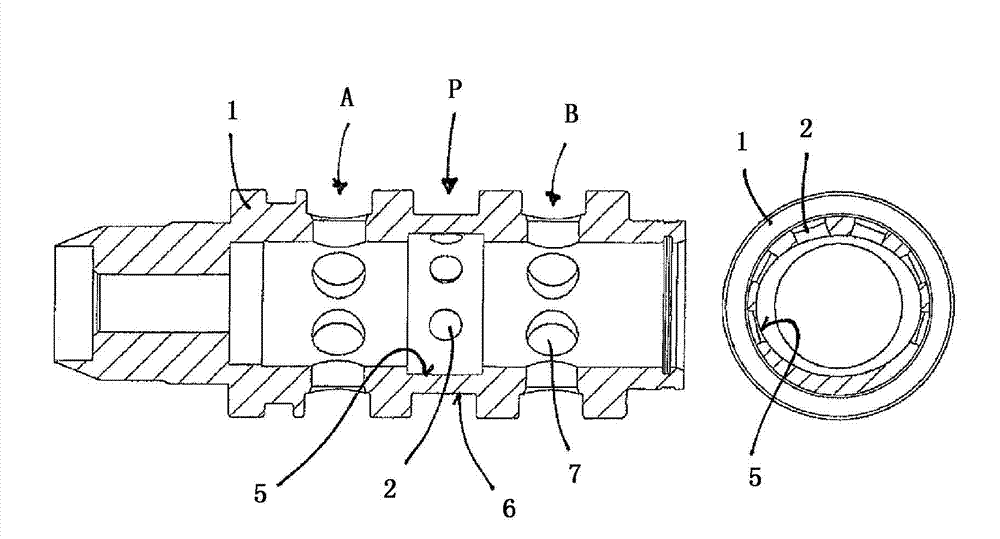

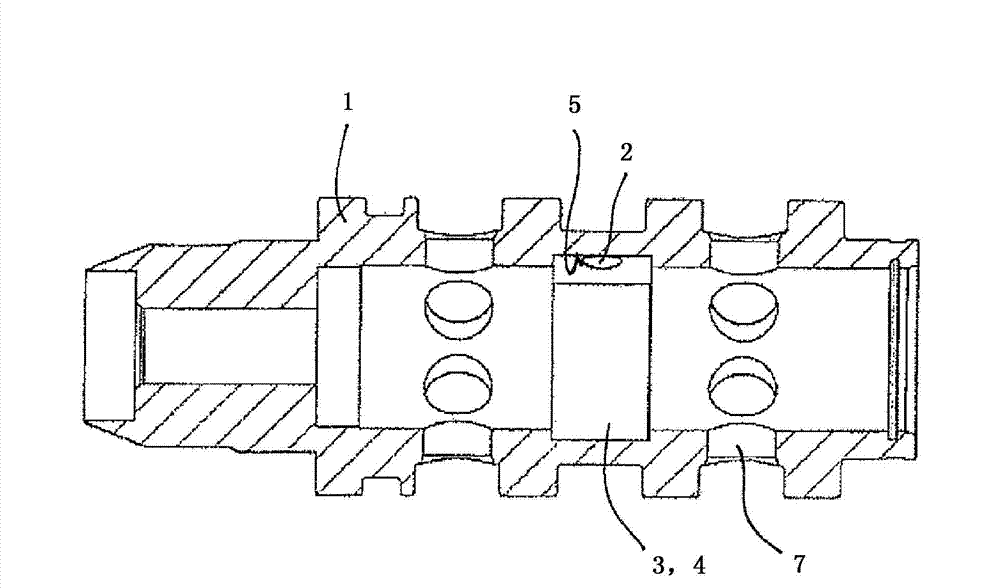

[0019] figure 1 and figure 2 The main elements of the control valve according to the invention, namely the elastic band 3 and the valve housing 1 , which can be used as check valve 4 , are each shown in a single view. exist image 3 and Figure 4 In the exemplary embodiment, the elastic strip 3 is inserted into the groove 5 on the valve housing 1 so that the elastic strip 3 bears against the groove 5 with a certain radial pretension. on the bottom of the tank.

[0020] as from figure 1 As can be seen in , the elastic strip 3, which can be used as a check valve 4, is bent into an oval shape so that the ends of the elastic strip 3 are spaced apart from each other. The spacing or opening between the ends of the oval shape ensures the elastic deformability of the elastic strip 3 inside the groove 5 . The width of the elastic strip 3 is constant and coordinated with the width of the groove 5 .

[0021] Such as figure 2 As shown, in the region of the opening 2 for hydrauli...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap