Method and device for the internal oiling of a gear shaft that is arranged coaxially to the oil pump of a gearbox and drives the oil pump

一种变速器、泵轴的技术,应用在传动装置零件、润滑剂导管装置、润滑泵的压力润滑等方向,能够解决制造及维护成本负面、装配耗费等问题,达到成本降低、装配耗费降低、效率提升的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

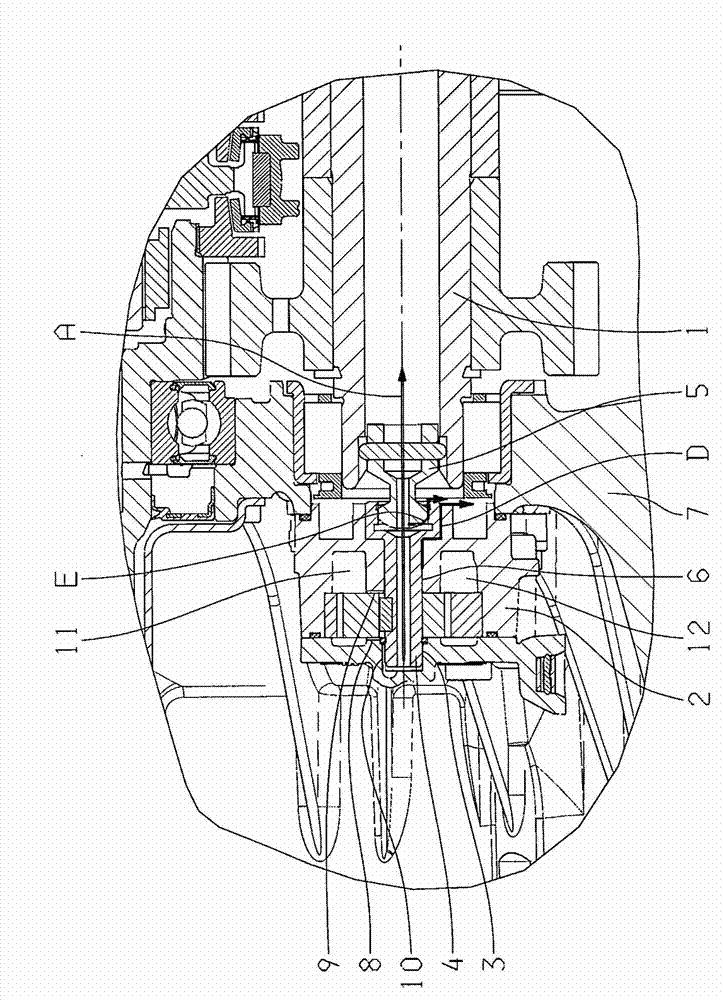

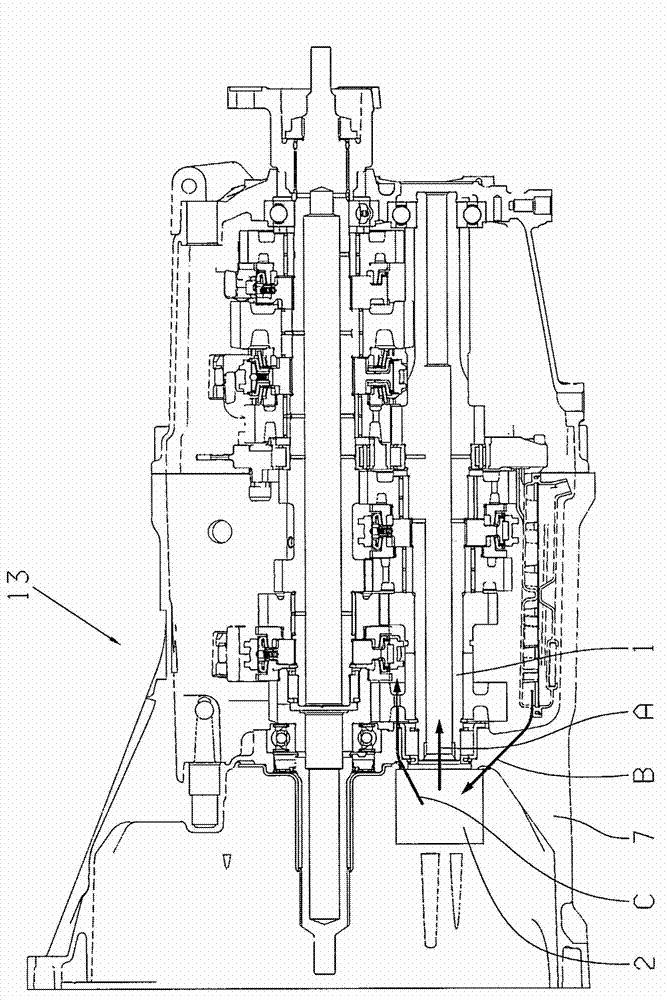

[0024] According to the invention, the internal oiling of the transmission shaft takes place via the already existing leakage oil of an oil pump integrated into the transmission. refer to figure 1 An oil pump 2 flanged to the clutch housing 7 is arranged coaxially with and driven by the transmission shaft 1 to be oiled.

[0025] According to the invention, leakage oil from at least one pump shaft bearing point 3 is guided into the pump shaft 4 which is designed as a hollow shaft and via a carrier which has an internal bore and connects the pump shaft 4 to the transmission shaft 1 to be oiled. 5 is transferred to the transmission shaft 1 which is to be oiled and which also has an inner bore. The leakage oil flow used to oil the inside of the transmission shaft 1 is in the figure 1 Indicated by arrow A.

[0026] In the event that the leakage oil quantity of the at least one pump shaft bearing point 3 is not sufficient for internal oiling of the transmission shaft 1 to be lubr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com