Pre-assembled structure assembly with friction clutch, corresponding transmission housing and corresponding motor vehicle

A technology for friction clutches and transmission housings, applied in clutches, fluid-driven clutches, mechanical-driven clutches, etc., to achieve the effects of reduced assembly costs, simple centering, and simple installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

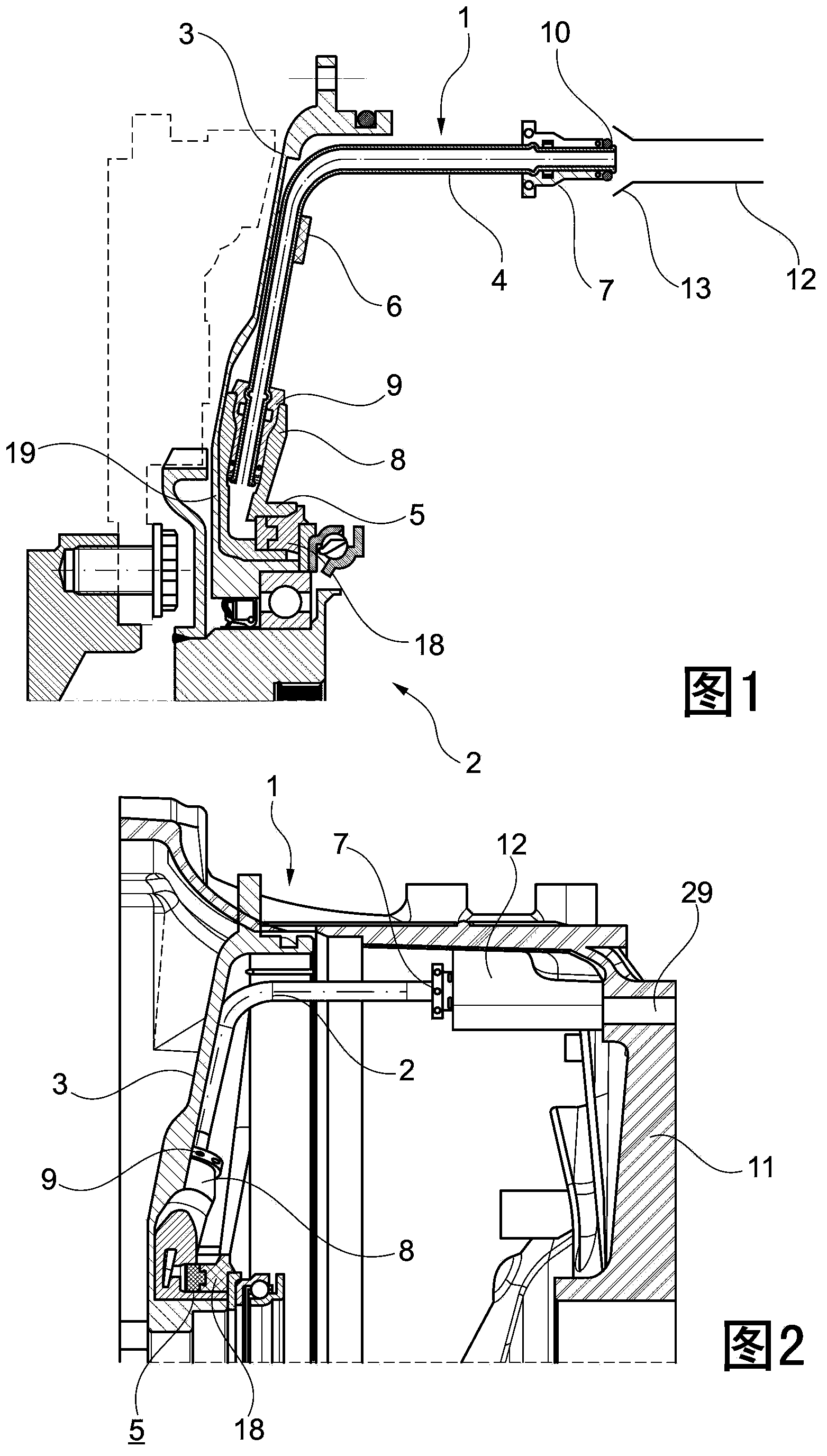

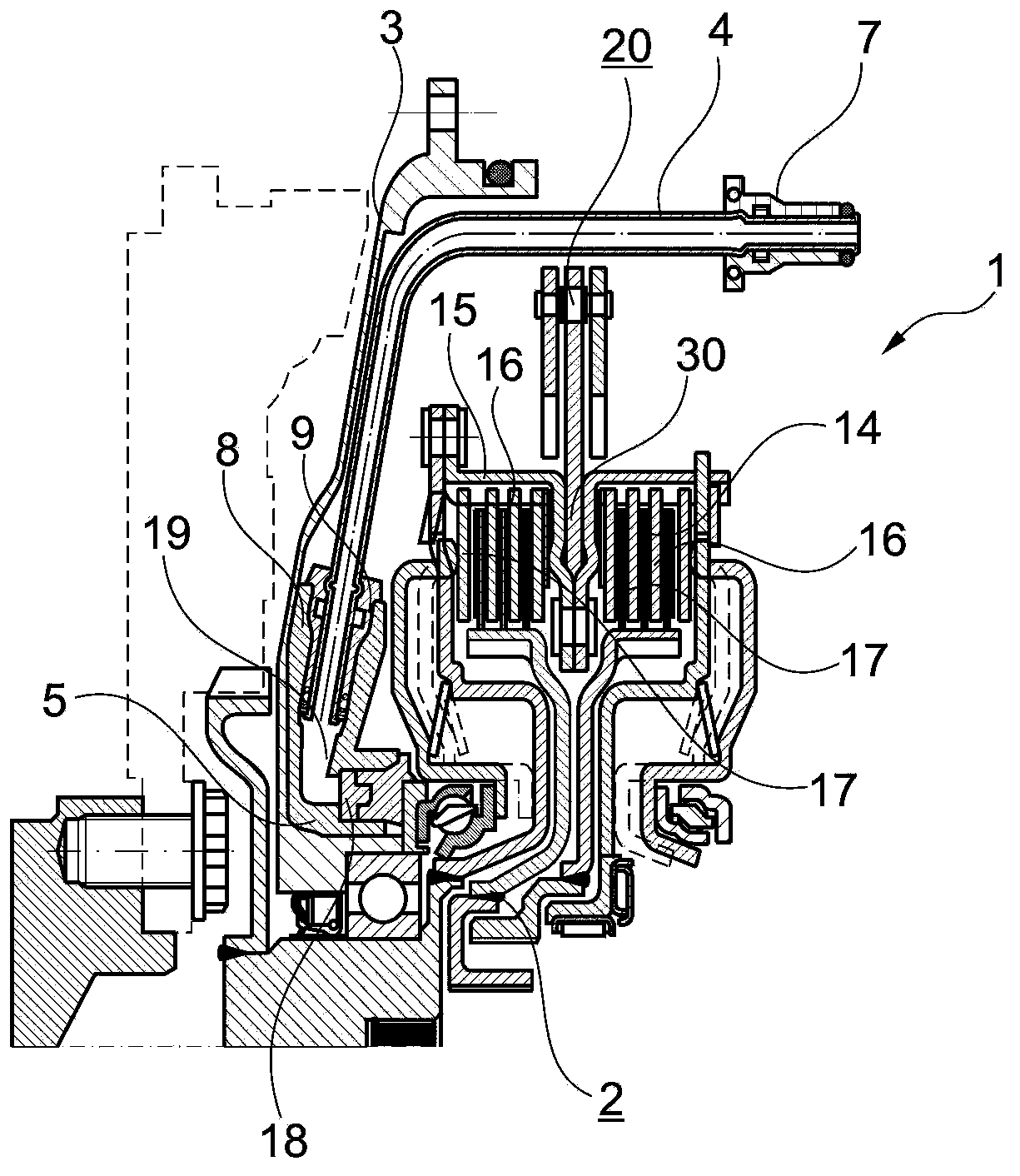

[0025] figure 1 A pre-assembled subassembly 1 is shown schematically with a friction clutch 2 , shown here only partially, with a clutch cover 3 . The friction partners of friction clutch 2 , which are not shown in this figure, can form one or more partial clutches. The at least one partial clutch is hydraulically actuated via slave cylinder 5 . For this purpose, the slave cylinder 5 is connected via a hydraulic line 4 to a master cylinder, not shown here, which is connected, for example, to a clutch pedal of a motor vehicle or operates automatically. Here, the hydraulic line 4 is fastened to the clutch cover 3 via a clamp connection 6 and has a connection 7 for connection to a counter-part (not shown here), which can be in the transmission housing or an intermediate part, for example. constitute. The hydraulic line 4 is preferably a rigid metal line, for example a rigid steel line. Via the extension 8 on the slave cylinder 5 and the corresponding extension 9 on the hydrau...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com