check valve

A technology of check valves and valve components, which is applied in the direction of lift valves, control valves, valve devices, etc., and can solve problems such as low height of oil column

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

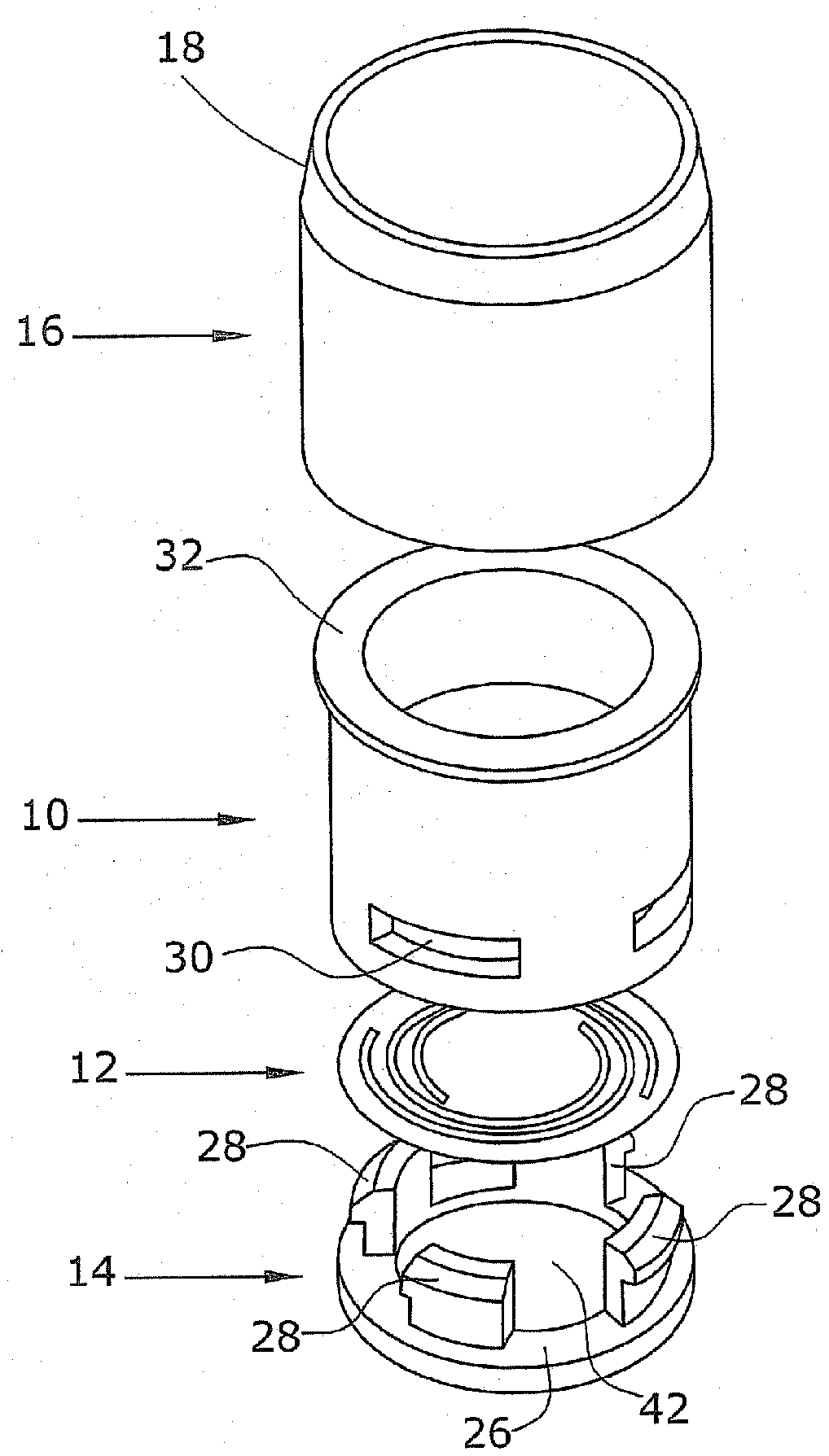

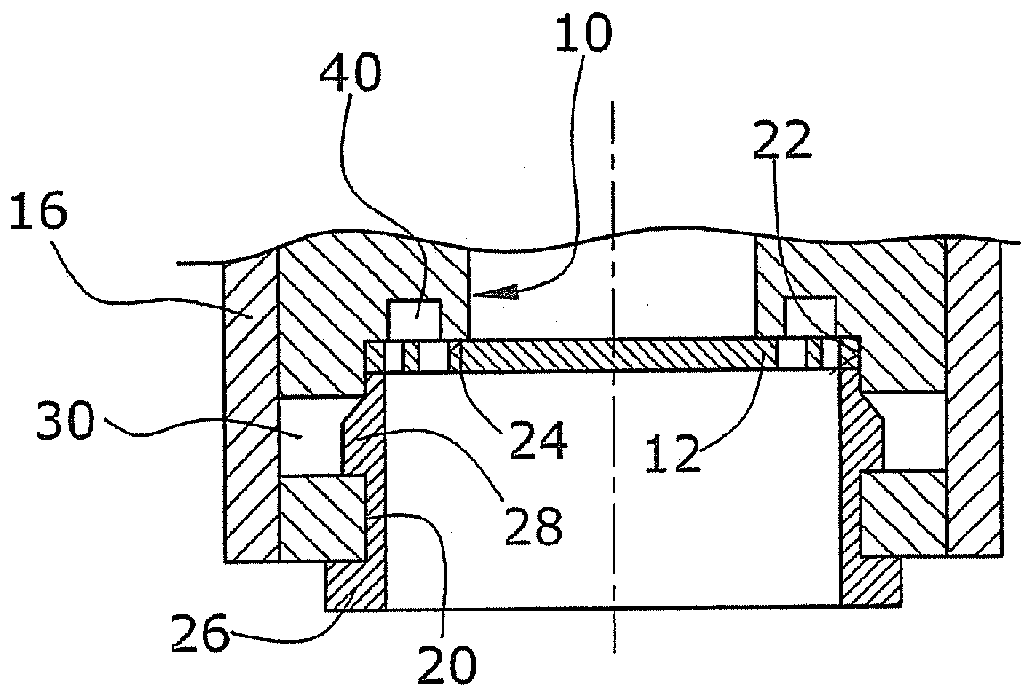

[0022] In the first preferred embodiment ( figure 1 and 2 ), the non-return valve has a plastic housing 10 in which a valve element 12 is arranged and fixed by means of a retaining element 14 . In the preferred embodiment, the housing 10 is surrounded by a metal sleeve 16 . In particular, the metal sleeve 16 can be inserted into an opening in the crankcase with an interference fit. The sleeve 16 has a section 18 in order to simply press the sleeve 16 into the opening with an interference fit.

[0023] In a first assembly step, the valve element 12 is figure 1 Inserted from below into the substantially cylindrical housing and fixed by means of fastening elements 14 .

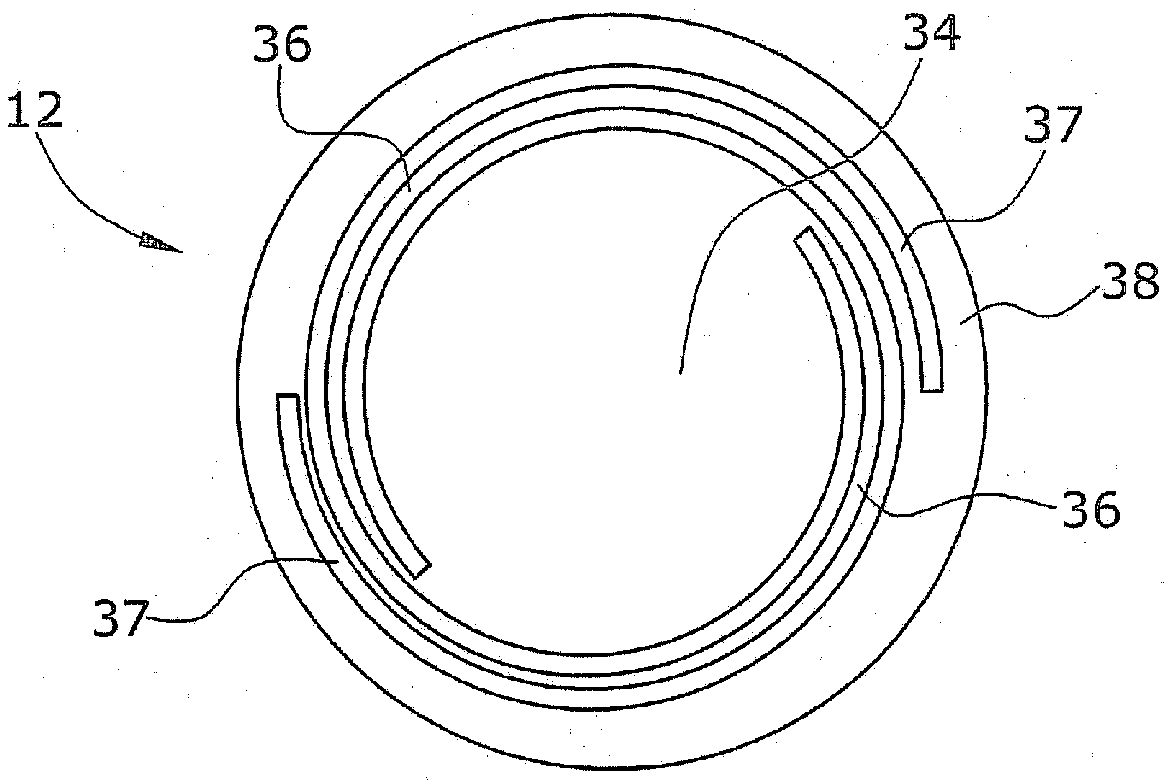

[0024] In order to ensure a secure fixation of the valve element 12 , in the exemplary embodiment shown the housing 10 has a cylindrical opening 20 through which the valve element 12 is inserted. Furthermore, the housing 10 has a platform and a constriction whose diameter is reduced to a cylindrical region 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com