air dryer

A technology of air drying and air dryer, which is applied in the directions of air treatment device, gas treatment, separation method, etc., to achieve the effect of reducing cost, reducing assembly cost and simplifying structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

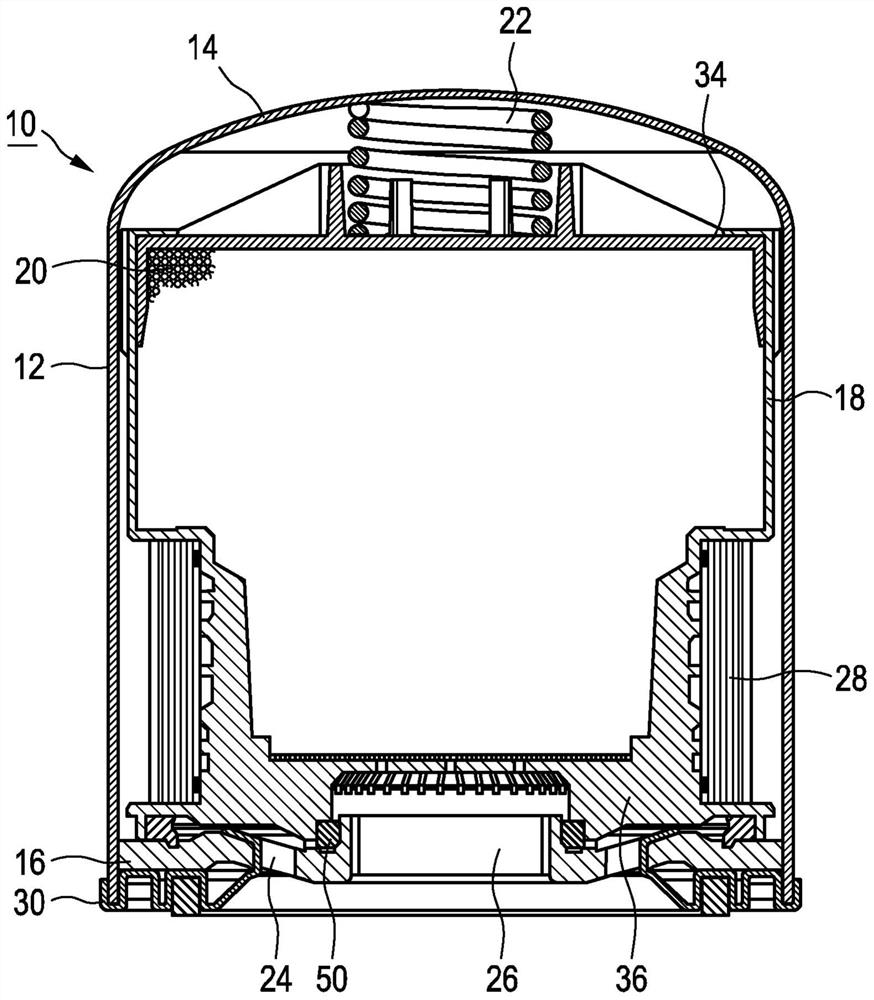

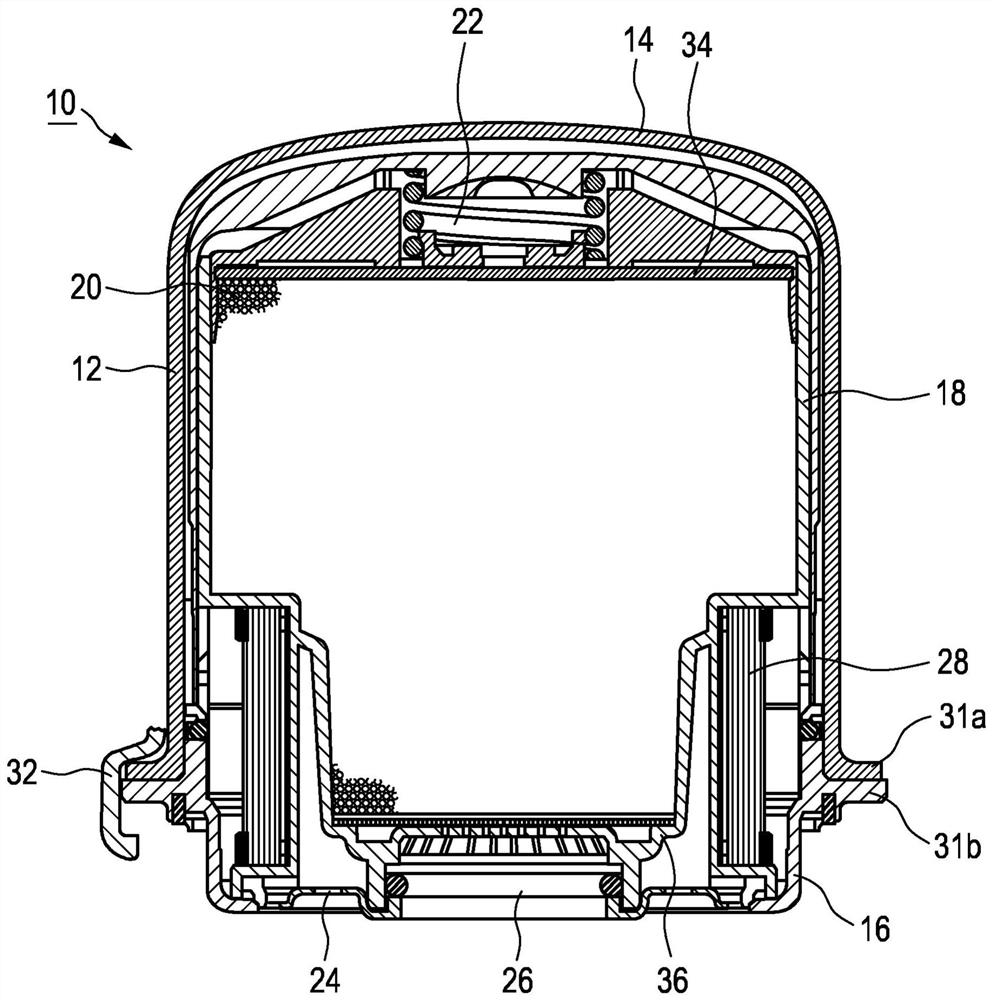

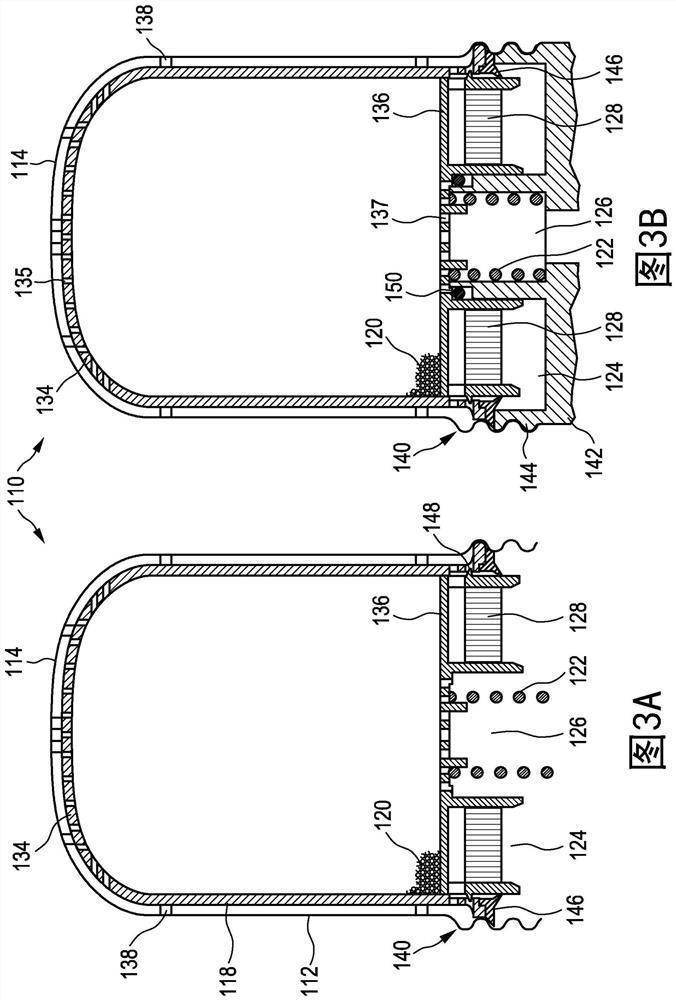

[0036] The invention is explained below in more detail by way of example with the aid of an air drying cartridge for a compressed air treatment device for a commercial vehicle. Components of the air drying cylinder according to the invention correspond to the components of the conventional air drying cylinder shown in FIGS. 1 and 2 and are designated with the same reference numerals, wherein the numeral "1" is added in front of these reference numerals.

[0037] In Figures 3 and 4, Figure A shows the air drying cartridge itself of the present invention, and Figure B shows the air drying cartridge assembled on the housing of the air dryer, respectively.

[0038] refer to Figure 3A and 3B , first, the air drying cylinder of the first embodiment of the present invention will be explained.

[0039] The air drying cartridge 110 has a substantially cylindrical cartridge housing 112 with a closed housing cover 114 which is formed in the form of a deep-drawn sheet metal. In the end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com