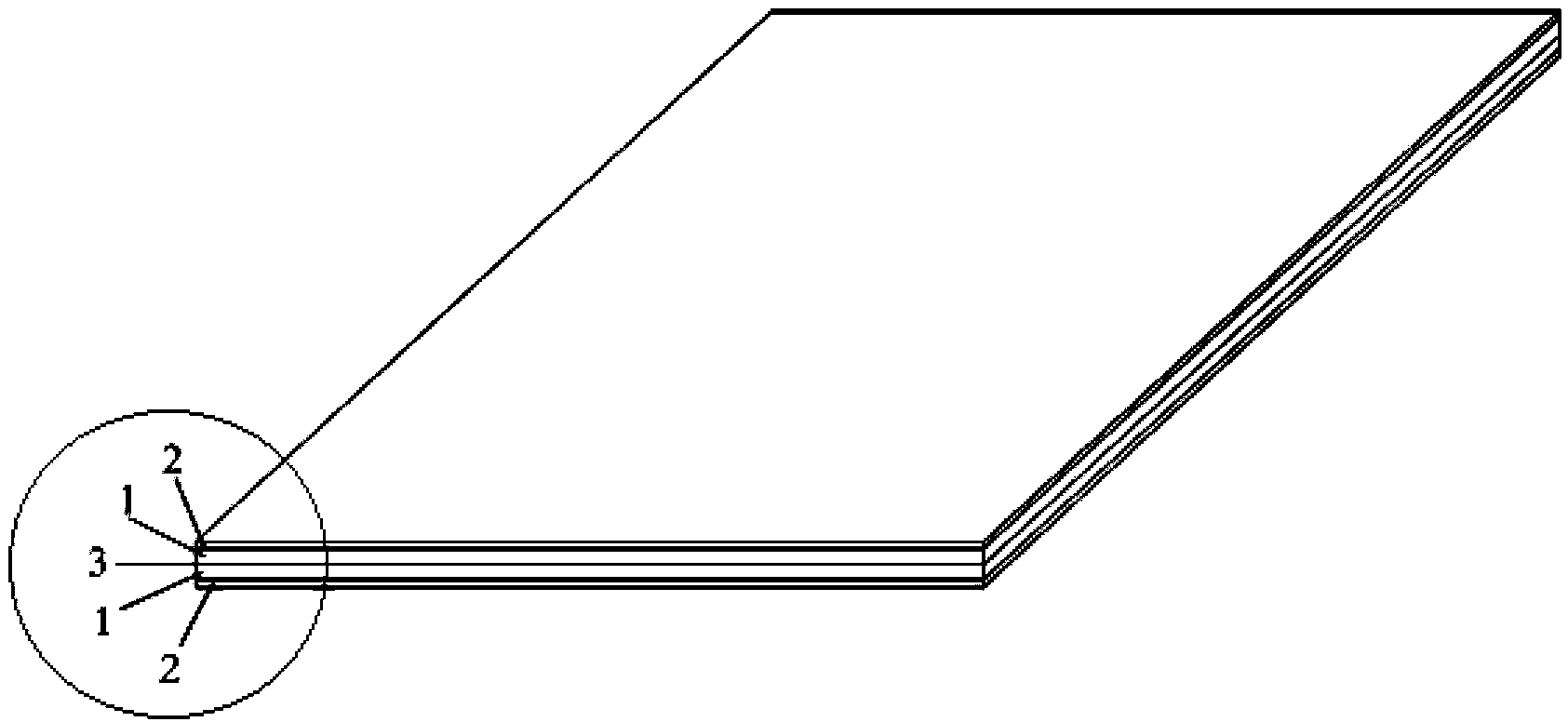

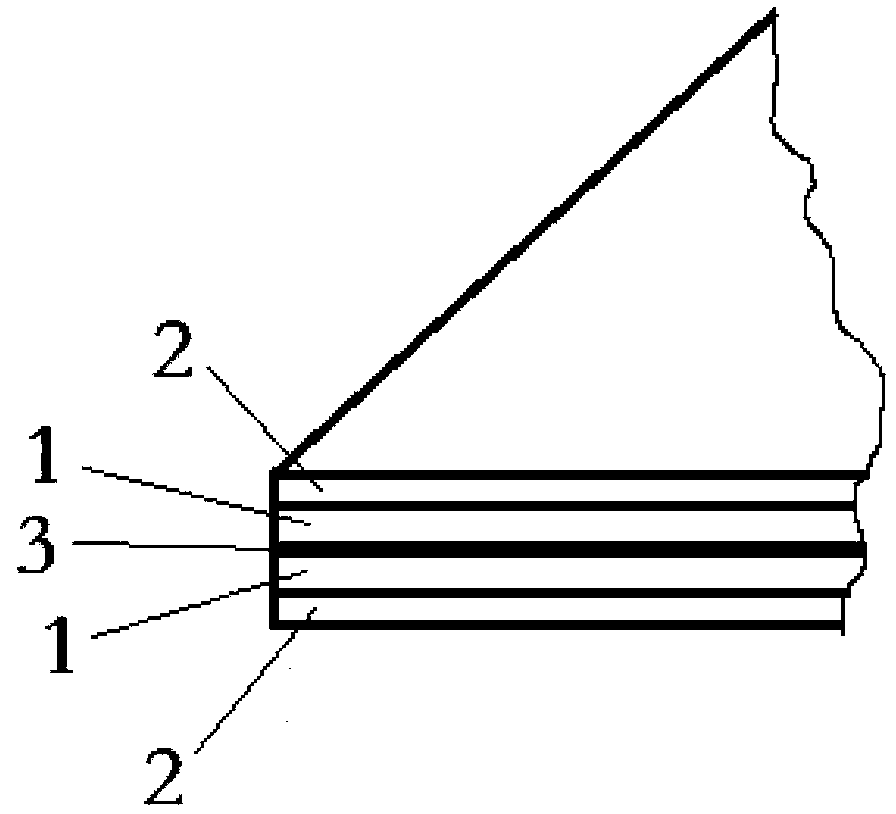

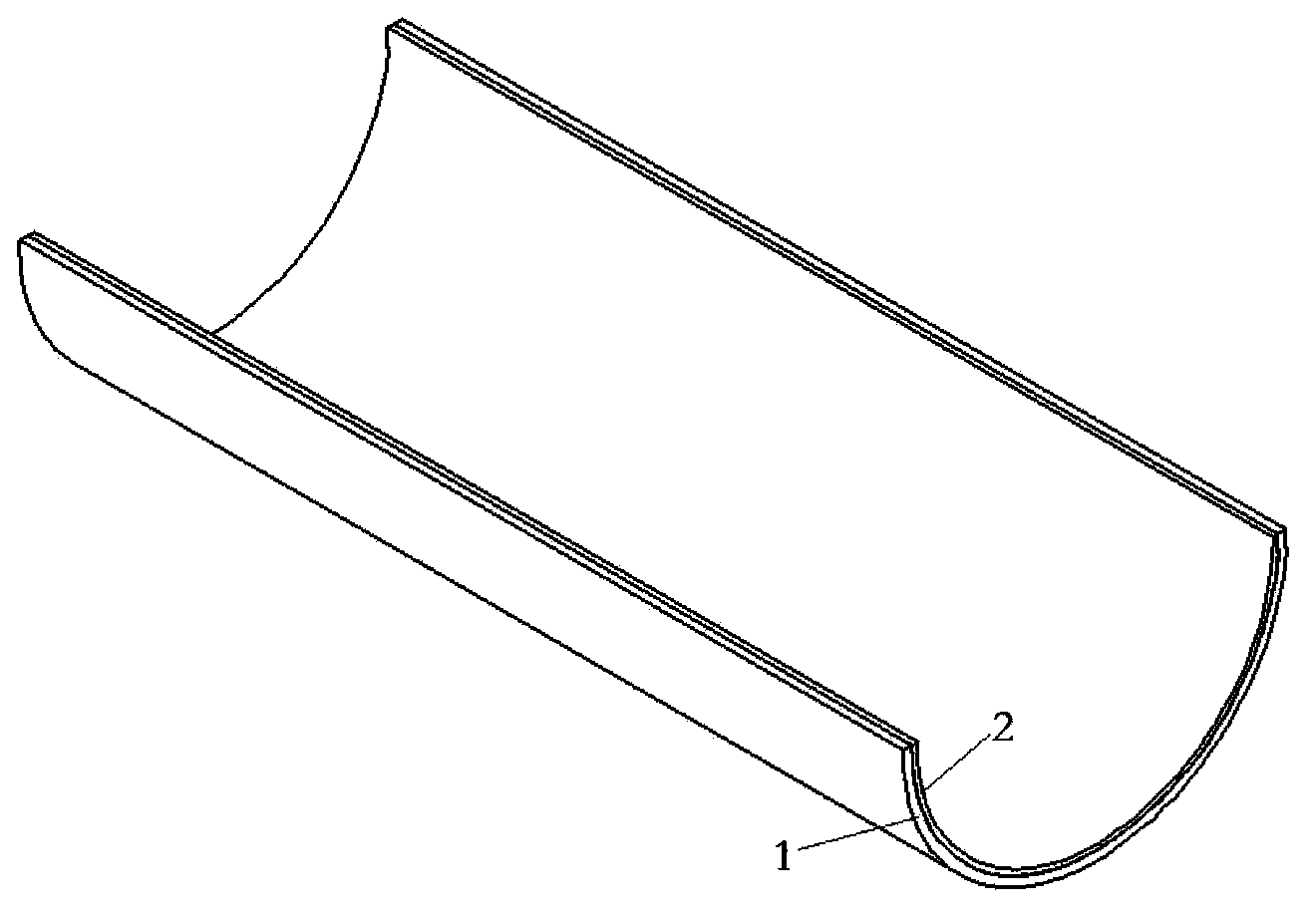

Shaft furnace cloth chute and manufacture method thereof

A technology of distributing chutes and blast furnaces, applied in the direction of arrangement of bells and funnels, etc., which can solve the problems of large differences in the properties of inner and outer layers of materials, and achieve the effects of small high-temperature deformation, consistent wear resistance, and reduced weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] In this example, the material of the lining layer is quenched and tempered wear-resistant steel NM360, the size is 20mm×2000mm×2200mm, and the quantity is 2 pieces; the material of the outer shell is low alloy structural steel Q345, the size is 30mm×2000mm×2200mm, the quantity is 2 pieces pieces.

[0037] The preparation method of blast furnace distribution chute comprises the steps:

[0038] 1) Surface cleaning: select two slabs of the outer shell layer and the inner lining layer of the blast furnace distribution chute with the same length and width, and clean any surface of the inner lining layer slab and the two surfaces of the outer shell layer slab to remove Surface oil, rust and oxide layer, and dry, the cleaned surface is clean and visible metallic luster;

[0039]2) Blank assembly: stack the four slabs cleaned in step 1) together in the order of inner lining layer, outer shell layer, outer shell layer and inner lining layer, and align all around; Spray or coat...

Embodiment 2

[0047] The material of the lining layer in this embodiment is quenched and tempered wear-resistant steel NM400, the size is 20mm×2000mm×2200mm, and the quantity is 2 pieces; the material of the outer shell is austenitic heat-resistant steel plate 0Cr18Ni9Ti, the size is 30mm×2000mm×2200mm, Quantity 2 pieces.

[0048] The preparation method of blast furnace distribution chute comprises the steps:

[0049] 1) Surface cleaning: select two slabs of the outer shell layer and the inner lining layer of the blast furnace distribution chute with the same length and width, and clean any one surface of the inner lining layer slab and the two surfaces of the outer shell layer slab to remove Surface oil, rust and oxide layer, and dry, the cleaned surface is clean and visible metallic luster;

[0050] 2) Blank assembly: stack the four slabs cleaned in step 1) together in the order of inner lining layer, outer shell layer, outer shell layer and inner lining layer, and align all around; Spr...

Embodiment 3

[0058] In this embodiment, the material of the lining layer is quenched and tempered wear-resistant steel NM360, the size is 20mm×2000mm×2200mm, and the quantity is 2 pieces; the material of the outer shell is 1Cr18Ni9Ti, the size is 30mm×2000mm×2200mm, and the quantity is 2 pieces.

[0059] The preparation method of blast furnace distribution chute comprises the steps:

[0060] 1) Surface cleaning: select two slabs of the outer shell layer and the inner lining layer of the blast furnace distribution chute with the same length and width, and clean any one surface of the inner lining layer slab and the two surfaces of the outer shell layer slab to remove Surface oil, rust and oxide layer, and dry, the cleaned surface is clean and visible metallic luster;

[0061] 2) Blank assembly: stack the four slabs cleaned in step 1) together in the order of inner lining layer, outer shell layer, outer shell layer and inner lining layer, and align all around; Spray or coat a layer of high-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com